AlN on Si Wafers

The semiconductor industry is constantly searching for new materials that offer better performance.

Existing materials, like silicon, have been pushed to their limits and we need a new material that can offer better performance.

UniversityWafer, Inc's Aluminum nitride on silicon wafers offers many advantages over existing materials. It has a low dielectric constant, which means it can be used to make smaller and faster transistors. It also has excellent mechanical properties, making it ideal for use in high-stress applications. And its low thermal conductivity makes it an ideal material for thermal management applications.

We have a large selection in stock. Please send us your specs for an immediate quotel.

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

Aluminum Nitride (AlN) on silicon wafers combine the high thermal conductivity and wide bandgap properties of AlN with the scalability and cost advantages of silicon wafers. AlN-on-Si templates are widely used for HEMT structures, RF and microwave devices, MEMS, and high-power electronics research where low defect density, strong thermal management, and compatibility with standard silicon processing are required. UniversityWafer, Inc. supplies AlN-on-silicon wafers in multiple diameters, orientations, and template thicknesses to support both academic and industrial R&D.

AlN Wafers Cassetted

![]()

What are Aluminum Nitride on Silicon Wafers?

Aluminum nitride (AlN) is a ceramic material that is often used in conjunction with Silicon (Si) in a variety of applications. The combination of these two materials can be used to create composite materials with improved electrical, thermal, and mechanical properties.

One common use of aluminum nitride silicon is in the production of high-frequency electronics, such as RF filters and power amplifiers. The combination of aluminum nitride and silicon allows for the creation of devices with improved thermal conductivity and high power handling capabilities.

Aluminum nitride silicon is also used in the production of microelectromechanical systems (MEMS), which are tiny devices that are made up of microelectronic and mechanical components. The combination of aluminum nitride and silicon allows for the creation of MEMS devices with improved thermal stability and electrical performance.

In addition to these applications, aluminum nitride silicon is also used in the production of LED lighting, in the aerospace industry, and in research and development for a variety of other applications.

Aluminum Nitride (AlN) on Silicon Wafers

We have a large selection of in stock AlN on Si wafers. See below for just some of what we have in stock. Let us know which item(s) interested you. Or please send us your specs and quanity for an immediate quote.

| AlN-on-Silicon Wafer Series – Prime Grade / For HEMT | ||||||||

|---|---|---|---|---|---|---|---|---|

| Diameter | Orient. | Substrate Thickness | Surface Finish | AlN Template | Conduction | Grade | Qty | Status |

| 2" | (001)/(111) | P/Boron Si | SSP | 25 nm | Un-doped, SI | Prime | 5–25 | By Order |

| 4" | (001)/(111) | P/Boron Si | SSP | 25 nm | Un-doped, SI | Prime | 5–25 | By Order |

| 6" | (001)/(111) | P/Boron Si | SSP | 25 nm | Un-doped, SI | Prime | 5–25 | By Order |

| 8" | (001)/(111) | P/Boron Si | SSP | 25 nm | Un-doped, SI | Prime | 5–25 | By Order |

| 6" | (001)/(111) | P/Boron Si | SSP | 100 nm | Un-doped, SI | Prime | 5–25 | By Order |

| 6" | (001)/(111) | P/Boron Si | SSP | 150 nm | Un-doped, SI | Prime | 5–25 | By Order |

| 6" | (001)/(111) | P/Boron Si | SSP | 200 nm | Un-doped, SI | Prime | 5–25 | By Order |

| Notice: | ||||||||

| 1. Custom AlN wafers available from 2"–8" | ||||||||

| 2. SSP = Single Side Polished | ||||||||

| 3. BSP = Both Sides Polished | ||||||||

| 4. Pricing depends on quantity | ||||||||

| 5. Available: Prime, Epi-ready, or As-grown | ||||||||

| 6. Template thickness uniformity: < 10% | ||||||||

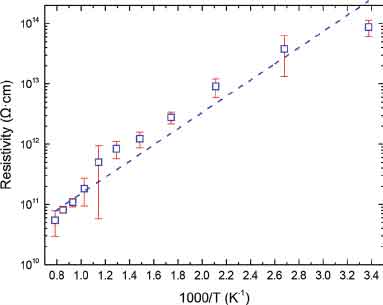

| 7. Resistivity > 10⁶ Ω·cm | ||||||||

How Aluminum Nitride on Silicon Wafers Can Help in Electronics

Aluminum Nitride on Silicon Wafers is a new type of semiconductor material that offers unique properties. The aluminum nitride ceramic has a low dielectric constant and excellent mechanical properties. It is non-toxic and has a linear expansion coefficient similar to that of silicon. In addition, it has low thermal conductivity. This combination of properties makes aluminum nitride an ideal material for many electronic applications.

A thin film of aluminum nitride is a form of semiconductor material. It is highly conductive and can withstand high temperatures. It is also resistant to electromagnets and has a high boiling point. As a result, it is commonly used in mobile phones and other electronics. However, it is not advisable to process Aluminum Nitride on Silicon Wafers without proper annealing.

and can withstand high temperatures. It is also resistant to electromagnets and has a high boiling point. As a result, it is commonly used in mobile phones and other electronics. However, it is not advisable to process Aluminum Nitride on Silicon Wafers without proper annealing.

Aluminum Nitride is also an excellent electrical insulator. It can be used in solar cells. But its high thermal conductivity makes it potentially hazardous when exposed to sunlight. Therefore, it is a good material for electronics. While it does not conduct electricity or heat, it is highly conductive. As a result, Aluminum Nitride is an excellent material for making semiconductors. It is a good alternative to Beryllium Oxide, and has similar thermal expansion properties to a silicon wafer.

Besides being a good electrical insulator, aluminum nitride on silicon wafers also has low thermal conductivity. For this reason, it is frequently used in solar cells. In addition, it is a reliable material in semiconductor devices. And it is also low in toxicity. But how can it help in electronics? The answer lies in the process of deposition. Aluminium Nitride on Silicon Wafers

The aluminum nitride on Silicon wafers is an ideal substrate material for many applications. It has similar thermal expansion properties to a silicon wafer and it is chemically inert. Its high thermal conductivity and low electrical resistance make it a suitable material for many electronic applications. This makes Aluminum Nitride on Silicon Wafers the best choice for electronics. And it's environmental-friendly.

Compared to silicon, aluminum nitride on silicon wafers has excellent electrical conductivity and a low thermal expansion coefficient. These properties make it a great semiconductor material. In addition to electronics, it is also safe for the environment. The material has low thermal conductivity and is a strong insulator. Its thermal resistance and high temperature resistance make it a great material for semiconductor applications.

Aluminum Nitride on silicon wafers are a great alternative to Beryllium Oxide for electronics applications. Its low cost and non-toxic properties make it a desirable alternative for a silicon wafer. This semiconductor material is also useful for electronic applications. It can also be machined. There are many advantages of using this material on a chip. It is a very versatile substrate for electronics manufacturing.

The material is extremely durable. It is suitable for a wide variety of electronic applications. Its low thermal conductivity and high electrical insulating ability make it a superior material for electronic devices. Unlike silicon, it is non-toxic and easy to fabricate. In addition to electronics applications, it has a low dielectric constant. It is also an excellent substitute for silicon in high-speed lasers.

Although aluminum nitride is a good thermal conductor, it can be toxic when exposed to it. It is also an excellent material for microelectronics and solar cells. It is non-toxic and eco-friendly. It is used in smartphones and other devices that require superior thermal insulation. It is also a good candidate for printed circuit boards. If it meets your specifications, it's a great choice for PCs.

Aluminum Nitride on Silicon Wafers is an excellent electrical and thermal insulator. It also resists corrosion. In addition to its electrical and thermal properties, it is also a good choice for semiconductors. But, when you choose a PCB for your VCSEL module, be sure to choose an aluminum nitride one. This material offers superior protection against heat and is an excellent choice for a PCB.

What Is Aluminum Nitride Used For?

What is aluminum nitride used in? Aluminium nitride is an inorganic compound consisting of aluminum and nitrogen, with the chemical formula AlN. Its properties include high thermal conductivity, electrical resistivity, and corrosion resistance. This compound is also known as azanylidynealumane. This material is manufactured by carbothermal reduction of aluminium oxide. During the manufacturing process, sintering aids are added to the alloy to make the final product dense enough to meet the technical specifications. The material is used for many applications, from surface acoustic wave sensors to insulators.

AlN is commonly available in substrates that are 1 mm thick and can be laser cut.  However, thicker forms of the material can be expensive to manufacture and may require a custom material and significant machining. In smaller quantities, the metal can be used for laser cutting or other manufacturing processes. A more versatile product is a semiconductor made from aluminum nitride based on gallium nitride.

However, thicker forms of the material can be expensive to manufacture and may require a custom material and significant machining. In smaller quantities, the metal can be used for laser cutting or other manufacturing processes. A more versatile product is a semiconductor made from aluminum nitride based on gallium nitride.

Aluminum nitride is a covalently bonded material. It has an hexagonal crystal structure and can be laser cut or etched. These types of nitride are stable at extremely high temperatures under inert atmospheres and form a layer of aluminum oxide on their surfaces. It is unstable in hydrogen and carbon dioxide atmospheres, and it dissolves and hydrolyzes slowly in water and mineral acids.

Aluminum nitride is a dense technical ceramic material that is very difficult to work with. It is difficult to process and machine, and it is not recommended for smaller scale manufacturing. As a result, it is most often manufactured in large scales. Aside from encapsulating semiconductors, it is also used for a variety of other applications. It can also be used to make optical materials and lenses.

Aluminum nitride is a very useful material in a variety of applications. It is a high-temperature material that has excellent electrical and thermal conductivity. It is also used in high-power electronics and LED lighting technology. It is also a good heat-dissipation material. Although it is a highly-conductive material, it is highly flammable and causes skin and eye irritation.

Aluminium nitride is an inert material. Its melting point is 2517 degC. Its thermal conductivity is approximately 4.9 mm/K. The material is stable in inert atmospheres and can be sintered in a variety of ways. It is highly resistant to molten metal. It is also an electrical insulator. Its thermal resistance makes it a valuable material for semiconductors.

What is aluminum nitride used in? It is a soft metal and has an oxidized surface. It is also an excellent conductor of electricity. It can be laser cut to produce light-emitting diodes. Some applications use this material for heat-shielding. It is very durable and can be applied in various areas. You can find it in almost any metal in a variety of applications.

Aluminum nitride is a technical ceramic material. It features high electrical insulation and thermal conductivity. It is mainly used in semiconductors and high-power electronics. It can also be found in mobile phones. A microelectromechanical system that contains AlN can be found in many modern smartphones. It is commonly used in RF filters. In addition, AlN is used as a piezoelectric layer in micromachined ultrasound transducers.

Aluminium nitride is a ceramic material with high thermal conductivity. It is commonly used as a semiconductor material because of its high thermal conductivity. Its high thermal conductivity makes it ideal for semiconductors. Its high electrical insulation properties make it a perfect material for sintered bodies. It is also used in many other applications. It is an excellent thermal dissipation material.

Aluminum nitride is an insulator ceramic with high thermal and electrical conductivity. It has a low expansion coefficient and is highly resistant to oxidation, so it is a suitable choice for many types of semiconductors. The high thermal and chemical resistance of aluminum nitride makes it a preferred material for a wide variety of uses. There are also many other applications where it is an excellent thermal and electrical conductor.