Could I get a quote for 50 MW-4-FHC (100mm Mock Aluminum Wafers)?

What are Mock Wafers and What are They Used For?

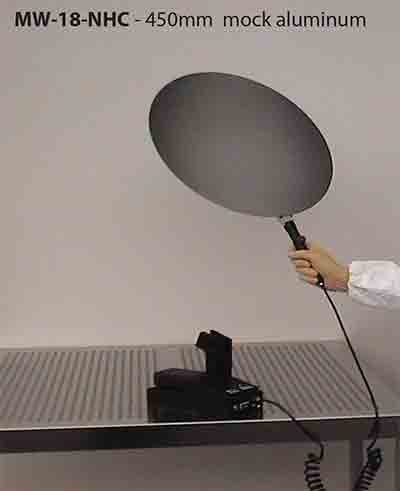

Mock Aluminum Wafers

Durable Mock aluminum wafers are durable. Unlike Silicon, they cannot be broken! Al wafers are medium to dark matte gray/black in color, and are 10 to 15% heavier than silicon wafers. Their diameter is within SEMI guidelines. Al wafers are perfect for prototyping and prototype manufacturing processes. These products also make handling wafers easy and safe.

An engineer at a semiconductor foundry requested the following quote:

Reference # 287693 for specs and pricing.

Get Your Quote FAST! Or, Buy Online and Start Researching today!

Custom Anodized Colors Available

What are Mock Aluminum Wafers Used For?

Mock aluminum wafers, also known as dummy wafers or test wafers, are used primarily in the semiconductor industry for various purposes, including equipment testing, calibration, and process development. These wafers are made of aluminum or other materials and are designed to mimic the properties of actual semiconductor wafers, such as silicon wafers, but at a lower cost.

The key uses of mock aluminum wafers include:

Equipment Testing and Calibration: Before running actual production wafers through semiconductor manufacturing equipment, mock wafers are used to test and calibrate the equipment. This ensures that the machinery is functioning correctly and is set up properly for the specific processes it will perform.

Process Development and Optimization: Engineers use mock wafers to develop new semiconductor fabrication processes or to optimize existing ones. Since these wafers are less expensive than actual semiconductor wafers, they provide a cost-effective way to conduct experiments and make adjustments without wasting valuable materials.

Training: Mock wafers are used for training purposes, allowing personnel to practice handling wafers and operating equipment without the risk of damaging expensive semiconductor wafers.

Troubleshooting: If there are issues in the manufacturing process, mock wafers can be used to troubleshoot and identify the source of the problem without the risk of ruining actual production wafers.

Overall, mock aluminum wafers play a crucial role in the semiconductor industry, helping to reduce costs and improve the efficiency and quality of the manufacturing process.

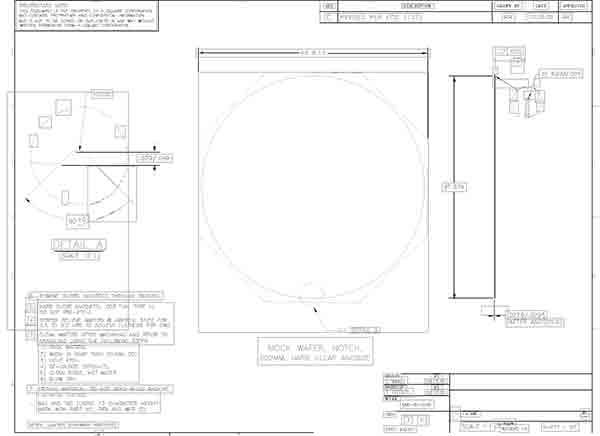

Aluminum Mock Wafers Silicon Replacement

Used as durable, shatterproof replacements for semiconductor silicon wafers for training, robotic calibration, particle shield, identification, equipment demonstration

and promotional applications. Mock wafers are precision manufactured from 6061 T-6 aluminum

alloy. Each Al wafer is chemically etched and heat-treated

to improve flatness and surface hardness and

durability. It is a medium to dark matte gray/black in

color. Each wafer is approximately 10% to 15% heavier

than a silicon wafer of similar size and profile. Dimensions

of diameter and notch are within SEMI standards.

Mock wafers can include silk-screened artwork,

engraving, color or other modifications on a custom

basis.

particle shield, identification, equipment demonstration

and promotional applications. Mock wafers are precision manufactured from 6061 T-6 aluminum

alloy. Each Al wafer is chemically etched and heat-treated

to improve flatness and surface hardness and

durability. It is a medium to dark matte gray/black in

color. Each wafer is approximately 10% to 15% heavier

than a silicon wafer of similar size and profile. Dimensions

of diameter and notch are within SEMI standards.

Mock wafers can include silk-screened artwork,

engraving, color or other modifications on a custom

basis.

| Wafer Size | Type | Ordering Park | Finish |

| 75mm | Flat | MW-3-FHC | Bare Aluminum |

| 75mm | Flat | MW-3-FNP | Hard Clear Anodized |

| 100mm | Flat | MW-4-FHC | Bare Aluminum |

| 100mm | Flat | WM-4-FNP | Hard Clear Anodized |

| 125mm | Flat | MW-5-FHC | Bare Aluminum |

| 125mm | Flat | MW-5-FNP | Hard Clear Anodized |

| 150mm | Flat | MW-6-FHC | Bare Aluminum |

| 150mm | Flat | MW-6-FNP | Hard Clear Anodized |

| 150mm | Notch | MW-6-NHC | Bare Aluminum |

| 150mm | Notch | MW-6-NNP | Hard Clear Anodized |

| 200mm | Flat | MW-8-FHP | Bare Aluminum |

| 200mm | Flat | MW-8-FNP | Hard Clear Anodized |

| 200mm | Notch | MW-9-NHC | Bare Aluminum |

| 200mm | Notch | Notch MW-8-NNP | Hard Clear Anodized |

| 300mm | Notch | MW-12-NHC | Bare Aluminum |

| 300mm | Notch | MW-12-NNP | Hard Clear Anodized |

| 450mm | Notch | MW-18-NHC | Bare Aluminum |

| 450mm | Notch | MW-18-NNP | Hard Clear Anodized |