Silicon for Laser Scan Mirrors

Silicon for Laser Scan Mirror

A researcher wanted to use our silicon wafers to fabricate a laser scan mirror.

Buy as few as one silicon wafer!

A researcher requested the following quote. I want to use your silicon wafer's mirror surface to fabricate laser scan mirrors. The problem is that I am not sure what to order?

Get Your Quote FAST!

What is a Laser Scan Mirror?

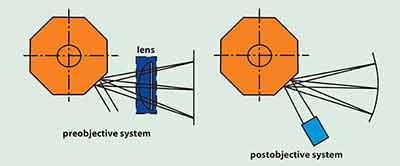

Laser scan mirrors redirect a laser beam to a specific location. The mirror sweeps the laser beam  across a surface or through a volume of space. Laser scan mirrors applications include 3D printing, laser cutting, laser engraving, and laser ranging. The shape of the mirror can be a flat mirror or a curved mirror, depending on the specific scanning system requirements.

across a surface or through a volume of space. Laser scan mirrors applications include 3D printing, laser cutting, laser engraving, and laser ranging. The shape of the mirror can be a flat mirror or a curved mirror, depending on the specific scanning system requirements.

Why Use Laser Scan Mirror?

The mirror has high laser damage threshold, which may satisfy requirements for stable, long-term operation of the scan mirror. Scanning Motion in Mirror Systems The scanning motion in the mirror system is affected by manufacturing errors, assembly gaps on each axis, the mirrors roughness, and the curvature of projection surfaces. There is no hysteretic movement on the line-pattern, which indicates the independent 2D movement of the mirror scanning system caused by two electromechanical actuators.

Reflection off retro-reflecting tape on the stylus

A laser scan mirror has two or more laser beams scanning above a planar surface. One or more of the beams may be retro-reflecting. If so, a sensor can be positioned near the light-reflecting perimeter and detected at the instant that the light beam impinges on the stylus. The resulting signal can be used to identify the point of the corresponding stylus.

The laser beams in the first and second scan planes are swept across the planar surface in a resonant manner. Each is nominally reflected off a light-reflecting perimeter located around the perimeter of the data surface. However, the tiniest amount of displacement from the surface causes the reflection to diverge from the plane.

Tangent to the centerline of the surface of the laser scan mirror

For optimal scanning, an optical scan mirror must be monolithic and have high performance and a low moment of inertia. In addition, it must have an effective heat dissipation mechanism. These requirements require the development of an improved scan mirror, which includes an optical and support section. The proposed solution simplifies the design and allows for highly efficient practical implementation.

Parabolic mirror focuses it onto a detector

A new, innovative method for generating a voltage signal during the impingement of a laser beam onto a stylus has been discovered. This method provides high scan frequencies, with minimal computation requirements.

Self-Calibration

Developing user-oriented calibration approaches is a hot topic in the laser scanner industry. For example, the Leica HDS 3000 and Callidus 1.1 self-calibrate their indoor 3D calibration fields.