My first choice would be free-standing n-type GaN, but I may be able to use GaN on sapphire or other substrates if the thickness is at or above the upper limit you specify of 10 microns. We will be making measurements with a scanning tunneling microscope so the samples should be relatively "flat" but I cannot specify a number for the bow, etc. This must be n-type GaN, and I would appreciate any specifications such as dopant type and approximate concentration, resistivity, crystal orientation, etc.

Scanning Tunneling Microscopy | Research & Production

Substrates Used for Scanning Tunnel Microscopy (STM)

A corporate scientist requested a quote for the following:

Please reference #205966 for specs/pricing.

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

Electron Tunneling Microscope Terms

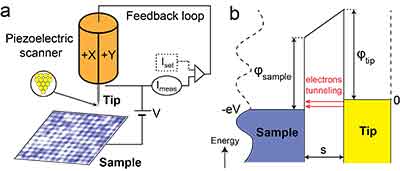

Scanning tunneling microscopy allows researchers to map the atom-by-atom surface of a conductive sample without using electron beams or light, and has been providing insights about matter at the atomic level for almost four decades. Scanning Tunneling Microscopy can be a difficult technique, requiring extremely clean, stable surfaces, sharp tips, great vibration isolation, and complex electronics. Scanning Tunneling Microscopy (STM) is an experimental technique that is based on the quantum tunneling principle of electrons between two electrodes separated by a potential barrier, typically used to image surfaces of materials at sub-atomic resolution.

- Scanning electron

- Probe microscopy

- Piezoelectric scanner

- Microscopy techniques

- Microscopy works

- Tunneling electrons

- Cconductive probe

- Force microscopy

- Electron microscopes

- Microscopes work

- Magnetic sample

- Probe tip

- Optical microscopes

- Tunneling currents

- Electron beams

Postdocs Using Silicon Wafers for Scanning Tunneling Microscopy

A postdoc requested a quote on the following:

I am looking for Si (111) P type B doped, res: 0.005-0.05 ohm, one side polished. The application is to calibrate a scanning tunneling microscope using the 7x7 Si(111) reconstruction. Ideally, the samples should be 1x10x0.5 mm (0.5 mm being maximum), but I can cut them to that size if need be. Do you have any product that meets these requirements?

Please reference #224408 for specs/pricing.

University Phd Using Gallium Nitride for Scanning Tunneling Microscopy

I'm writing to ask for a quote for a GaAs crystal with the following requirements: Resistivity at 77K or 4K less than 1 Ohm*cm, with possible n-doping Possibility to cleave on 110 facet Thickness between 0.2 mm and 1 mm Radius of 1-2 Inches Please let me know if this would be possible. I am asking for the crystals to use for Scanning Tunneling Microscopy measurements.

Reference #262927 for specs and pricing.

PhD Students Use Silicon Carbide Substrates for Scanning Tunneling Microscopy

I am a PhD Student. We are looking to purchase 4H-SiC wafer that has C-face epi-ready / cmp polished. Could you please provide quote for such product?

We'd like 4H-SiC (0001) research grade with C-face cmp polished. Wafer size isn't too important for us, but around 3" diameter would be good.

Our plan is to use this to make epitaxial graphene by annealing the SiC at high temperature in ultra-high vacuum and probe with scanning tunneling microscope.

Reference #269522 for specs/pricing.

What is Scanning Tunneling Microscopy

Scanning tunnelling microscopy (STM) was used for the first time to create a high-resolution image of a single atom-thick layer of silicon. Scanning tunneling, using an orderly vertical side surface 111 with a diameter of 1.5 mm and a depth of 0.1 mm. The structure of silicon and its interaction with other materials such as glass, metal and silicon dioxide (S2) are investigated with scanning tunnelling microscopes. Scanning Tunnelings, a view of two-dimensional silicon at a low level and its interactions with each other by means of scanning tunneling. Scanning tunnellers, where the order of 111 sides of each surface is ordered by the thickness of one-hundredth of an inch (1 mm) on each side. [Sources: 2]

Under the scanning tunnelling microscope there is an extended STM of Si-100, which shows darker structures next to the atomic stages. Scanning tunnelling microscope, in which the ST M is extended and shows the dimers and structure of the neighboring atomic step. [Sources: 6]

Scanning tunneling microscope with a function - oriented scanning method for Si-100, a high resolution image of the atomic structure of a Si-100 atom. [Sources: 9]

Scanning tunneling microscope with a functional - oriented - scanning method for Si-100, a high resolution image of the atomic structure of a Si-100 atom. [Sources: 5]

However, the optical image interface of mobile phones is not designed for microscopy and creates distortions in the imaging of microscopic samples. Repeated measurements can be made with a mobile phone without a high-resolution camera and using a microscope. [Sources: 5, 11]

Scanning tunneling microscopy can provide a lot of information on the topography of a sample when used with adaptation. With the adaptation, the information obtained is almost limitless, and it is possible to visualize different facets of the system under investigation. [Sources: 10, 15]

STMs, like lithography, can be used to tunnel electrons without changing the actual sample surface and without altering the surface of the sample itself. [Sources: 9]

The ability to replace silicon lattices with arsenic atoms in a controlled manner is important for the replacement of isolated dopan atoms, which is necessary if the dopan substances are to be activated. STM-based methods that investigate graphene-aln heterojunctions are also interesting because of the potential for their use in the manufacture of electronic devices. Further applications of advanced STM and methods will contribute to the development of novel devices that incorporate high-performance, cost-effective and highly efficient electronic components. The use of nano-fats based on graphene and alN represents a major development in scanning probe microscopy. [Sources: 0, 1, 3]

The laboratory has developed an automated tissue processing system with a slide-activated monochromatic aberration corrected dual-beam scanning probe microscopy system. This is a novel imaging technique aimed at developing high-performance, cost-effective and highly efficient imaging systems for biomedical applications. [Sources: 5]

In this microscope, an extremely sharp needle is used to feel atoms and molecules during scanning, similar to a laser beam. The STM is beamed into an electron-based microscope that uses the quantum mechanical effects of tunnelling. [Sources: 13, 14]

Electronics are needed to measure the current, scan the tip and translate the information into a form that can be used for STM imaging. [Sources: 4]

In semiconductors, we work on the STM branching, which is considered as a band - bending potential. Based on the measurement of the current at the tip of the sample, the STM can analyze the conductor of a semiconductor sample. The strip bends must be analysed for quantitative variations of the load carrier distribution, which are derived from the StM measurements. [Sources: 0, 7, 11]

To build up the potentials, we use CPD voltage mapping, and the position of the hydrogen atoms is determined by Fourier image analysis. The oxide thickness is between 0.32 and 1.0 - 35 nm, as can be seen from the scan and shown at junction 72. We use a high-resolution laser scanning tunnel microscope (HSTM) to determine the locations of each hydrogen atom by Fouriers image analysis. [Sources: 0, 8]

Simultaneously with the latest developments in molecular electronics, the ability to study the structure and properties of materials on atomic length scales up to 16 nm has advanced. In addition to AFM, Binnig and Rohreras' scanning tunneling microscopes have produced a number of related instruments and techniques that have revolutionized the ability to observe, study, and manipulate previously unobservable materials such as semiconductors and semiconductors. [Sources: 11, 12]

Sources:

[1]: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC7146850/

[2]: https://phys.org/news/2017-10-image-perfectly-smooth-side-surfaces-d.html

[3]: https://www.mdpi.com/2079-4991/10/9/1794/htm

[4]: https://www.nanoscience.com/techniques/scanning-tunneling-microscopy/

[5]: http://optimusconstructora.com.pe/weykv/american-optical-series-110-microscope.html

[6]: https://luxentrealty.com/k0zlv/si-band-structure-vasp.html

[7]: https://www.nrel.gov/materials-science/scanning-tunneling.html

[8]: https://www.nature.com/articles/s41467-018-05171-y/

[9]: https://en.wikipedia.org/wiki/Scanning_tunneling_microscope

[10]: http://mhamidian.com/si-stm/

[11]: https://www.pnas.org/content/102/25/8838

[12]: https://www.ibm.com/ibm/history/ibm100/us/en/icons/microscope/

ues/electronic/microscopy/

What are Challenges Associated With Scanning Tunneling Microscopy (STM)

Scanning Tunneling Microscopy (STM) is a form of microscope that allows scientists to see surfaces at an atomic level. Developed in 1981, STM was invented by Gerd Binnig and Heinrich Rohrer of IBM Zürich. They were awarded the Nobel Prize in Physics for this discovery in 1986. In the meantime, STM continues to revolutionize the field of science by enabling scientists to examine objects with ten times the lateral resolution of a conventional microscope.

STM uses a nanoscale probe to measure the topography and local electronic properties of a sample

STM operates in two modes: constant height mode and constant current mode. Constant height mode involves maintaining the probe tip at a constant height while scanning the sample. The tip then measures changes in the tunneling current at different locations. Constant current mode is suited for a variety of surfaces and can be used to image the topography and local electronic properties of a sample.

The most common type of STM measurement is topograph measurement. It involves rastering the tip across the sample at a fixed bias V and adjusting the position of the probe in z-direction so that the measured current remains at a predetermined setpoint value. Topographic measurements can be used to determine the shape of crystals, nanoparticles, and metal surfaces.

STM is a form of scanning probe microscopy that uses a nanoscale probe to measure the surface topography and local electronic properties of a material. Researchers can use this technique to map materials in nanometer-scale detail and manipulate individual atoms. It has transformed nanotechnology and continues to play a key role in research.

STM can also be used to analyze biological samples. The STM tip is held in contact with the membrane via a feedback loop. Unlike contact mode AFM, the STM tip cannot follow an AFM tip, which oscillates at a ca. 90kHz. Therefore, the topography of the membrane is revealed.

STM can image objects at ten times the lateral resolution of a conventional microscope

A scanning tunneling microscope can image objects with a lateral resolution of 0.1 nanometers. It can also create 3-D surface images. These images are recorded digitally, allowing for further processing. These microscopes are highly accurate and can image objects at ten times the lateral resolution of a conventional microscope. However, they can be tricky to use.

One major advantage of a scanning tunneling microscope is the ability to image objects at ten times the lateral level. This enables scientists to see subtle details of a specimen's structure. While traditional microscopes use three lenses to magnify objects, scanning tunneling microscopes can image objects up to 0.1 nanometers in width, making them the most detailed and accurate tools for detecting viruses and other pathogens.

The main drawback of the scanning tunneling microscope is that its electron conductivity is not as good as that of biological samples. This is a significant barrier for the application of the STM, which is why it is not widely used for biological samples. But these two instruments are similar in principle, and the STM has many benefits. It can image objects up to 0.1 nanometers in size, which is about 10 times more than conventional microscopes can image.

The scanning tunneling microscope was invented in 1981 by Gerd Binnig and Heinrich Rohrer at the IBM Zurich Research Center. Its high lateral resolution allows researchers to view objects down to the atomic level. It is even possible to image individual atoms. In addition, it can reveal the density of electrons on a surface. These microscopic particles play important roles in radioactive decay, so they can't be easily detected with conventional microscopes.

STM can also image objects at a higher lateral resolution than conventional microscopes. Its lateral resolution is ten times higher than conventional microscopes. The STM is capable of imaging objects at ten times the lateral resolution of a conventional microscope. These improvements can greatly increase the productivity of the microscope. The STM's lateral resolution is a key factor in determining the quality of microscopy.

STM can image objects at 0.1 nanometer

A scanning tunneling microscope is an instrument for imaging materials at a microscopic scale. It works by utilizing an electrical current to image objects at a fraction of a nanometer. Its lateral resolution is ten times greater than that of a traditional microscope. It can image objects at 0.1 nanometers and is particularly useful for studies in the nanoelectronics industry.

The basic physics of scanning tunneling microscopy can be modeled using the quantum mechanics of electrons. In a quantum mechanical model, an object hitting a wall would bounce back and pass through the wall, but an object of a small mass would pass through. Electrons are wavelike particles, and their wavelike nature results in greater probability of tunneling than larger mass objects.

In order to view the smallest objects in the universe, a microscope must be able to view their atoms. Using traditional light microscopy, objects can only be observed up to 500 nanometers in size. Alternatively, electrons can be used as a substitute for visible light. The latter is more accurate and has a much lower wavelength. A good light microscope is capable of imaging objects up to 500 nanometers.

The main components of a scanning tunneling microscope include a conducting tip, a piezoelectrically controlled height, an x-y scanner, and a computer. The scanning tip's radius of curvature dictates the resolution of an image. If two tips are used, double-tip imaging occurs, which means that two tips contribute to tunneling. Carbon nanotubes are used to produce sharp tips.

STM uses a piezoelectric effect, which was discovered by Pierre Curie in 1880. This effect is caused by a voltage across the crystal. The voltage reverses the effect, elongating or compressing the crystal. STM uses piezoelectric materials to scan objects. One typical piezoelectric material is lead zirconium titanate.

Is Scanning Tunneling Microscopy (STM) Noisy

STM is a type of microscope that uses a nanoscale probe to measure surface topography and local electronic properties. These measurements allow the creation of a map of surface properties that has resolution exceeding that of the optical microscope. This technique can even visualize single atoms. However, there are many limitations and challenges associated with STM. Here are some of them. This article will discuss the key challenges associated with STM.

Noise is an inherent problem in scanning tunneling microscopy, and the primary challenge is reducing its effect on image quality. One way to reduce noise is to design a microscope with an active mechanical noise cancellation system. This design features two independent STMs that share a nearly identical mechanical transfer function. This enables the instruments to sense almost identical background mechanical noise. Another method, called active mechanical noise cancellation (AMNC), involves applying noise to the second STM. This technique results in a dramatically improved signal-to-noise ratio.

Noise is an intrinsic problem in scanning tunneling microscopy, especially when the samples are tiny. This is a major obstacle to performing high-quality imaging. Fortunately, the technology is evolving at a rapid pace. For instance, it is easier to improve the image quality of a large sample than a small one. Moreover, this technology requires less mechanical noise than the conventional STM method. This is because the sample-tip tunnel junction is very stable.

The STM operates by applying a bias voltage between the tip and the sample. The magnitude of the current varies according to the sample's electronic properties and topography. However, the characteristic decay length of the STM tip is about one tenth of a nanosecond. However, the electron-hole-hole ratio and the characteristic height are important parameters that affect the resolution of the final image. Despite these limitations, STM is an essential tool for researchers.

Despite the high noise, STM has improved image quality and resolvability with the number of images. Its noise-to-signal ratio increases as the sample temperature increases, which makes STM more noisy. The noise-to-pixel ratio of an image is proportional to the number of averaged frames. This is related to the standard deviation of noise. However, STM is noisy, but its improvements are impressive and should be explored.

Video: Scanning Tunnel Microscopy (STM) Explained