⚡ Rapid Metal Coatings

Gold (Au) / Titanium (Ti)

Standard adhesion stack: 50nm Ti + 100nm Au.

Available on Silicon, Glass, or Sapphire.

Request a Coating Quote

Specify your substrate, film materials, and thicknesses.

Or, Buy Online and Start Researching Today!

Substrates We Coat

- Silicon Wafers: Prime, Test, and Mechanical grades.

- Glass Wafers: Fused Silica, Borofloat 33, Soda Lime.

- Sapphire: C-plane, R-plane, and A-plane.

- Ceramics: Alumina (Al2O3) and Aluminum Nitride (AlN).

- SOI Wafers: Silicon-on-Insulator substrates.

- Customer Supplied: We can coat your own wafers.

Thin Film Deposition Capabilities

UniversityWafer provides both R&D and production-scale coating services using advanced Sputtering (Perkin/Elmer 4410, MRC 903) and Electron Beam (E-Gun) Evaporation systems.

1. Sputtered Films Inventory

Sputtering is ideal for alloys, dielectrics, and achieving excellent adhesion.

| Category | Materials Available |

|---|---|

| Conductive Metals | Aluminum (Al), Gold (Au), Silver (Ag), Copper (Cu) |

| Adhesion Layers | Titanium (Ti), Chrome (Cr), Ti-W (90/10) |

| Refractory Metals | Molybdenum (Mo), Tungsten (W), Tantalum (Ta), Niobium (Nb) |

| Magnetic Metals | Nickel (Ni), Iron (Fe), Cobalt (Co) |

| Dielectrics (Oxides) | SiO2, Al2O3, TiO2, ITO (Indium Tin Oxide) |

| Nitrides | Silicon Nitride (SiN), TiN, TaN |

2. E-Beam Evaporated Films

Evaporation allows for high-purity deposition and lift-off processing.

| Category | Materials Available |

|---|---|

| Noble Metals | Platinum (Pt), Palladium (Pd), Gold (Au) |

| Soft Metals | Indium (In), Tin (Sn) |

| Oxides | Hafnium Oxide (HfO2), Yttrium Oxide (Y2O3), Indium Oxide (In2O3) |

| Fluorides | MgF2, CaF2, BaF2 (for optical coatings) |

Application Spotlights & Case Studies

🔋 Case Study: Carbon Coatings for Conductivity

Challenge: A researcher needed a conductive, amorphous Carbon thin film (1-2µm) on 4-inch SOI wafers. The goal was to create an electrically conducting film that was not shiny.

Solution: We utilized a specialized sputtering process to deposit Carbon. While 1-2µm is difficult due to stress, we successfully deposited ~8,000Å (0.8µm) with a refractive index of n=1.25 (indicating a Diamond/Graphite mix). The measured film stress was 913 MPa (compressive).

💎 Case Study: Diamond-Like Carbon (DLC)

Application: Hard coatings for wear resistance.

We supplied 100mm Silicon wafers coated with single-crystal Diamond films (CVD epi). The client requested thicknesses of 0.25µm and 0.50µm on Si(111) substrates, which are preferred for subsequent etching of pyramidal holes.

⚡ Case Study: Electrochemical Impedance

Application: Bio-sensing electrodes.

Researchers studying amyloid B-Oligomers utilized our Gold-Coated Silicon Wafers as stable electrodes for Electrochemical Impedance Spectroscopy (EIS). The inert nature of gold on silicon provides a perfect platform for sensitive biological measurements.

Understanding the Process

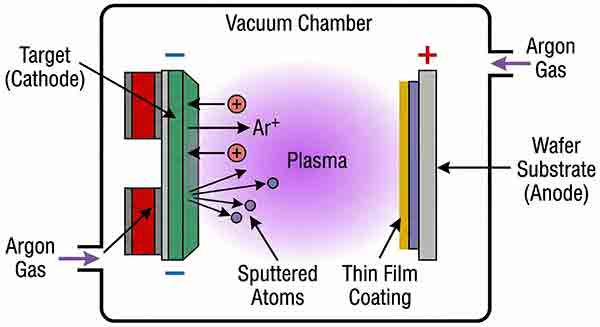

Sputtering

Sputtering involves ejecting material from a "target" source onto the wafer using high-energy plasma. It offers excellent step coverage and adhesion, making it ideal for coating complex topographies or MEMS devices.

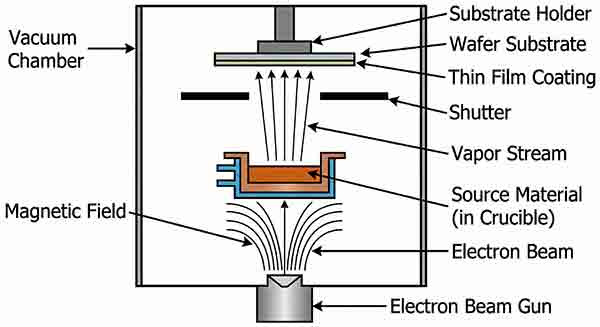

E-Beam Evaporation

An electron beam melts the source material in a vacuum, causing it to evaporate and condense on the wafer above. This method is preferred for "lift-off" processes and depositing high-melting-point metals like Tungsten or Platinum.