🔵 Best Seller: C-Plane Sapphire

2 Inch (50.8mm) Wafer

Orientation: C-Plane (0001) ±0.2°

Thickness: 430µm

Polish: Single Side Polished (SSP)

The standard substrate for GaN LED research.

Sapphire Quote Request

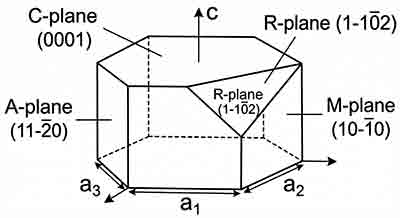

Specify Orientation (C, R, A, M) and Grade.

Or, Buy Online and Start Researching Today!

Why Buy From Us?

- All Orientations: We stock C, R, A, and M-plane.

- Small Quantities: Buy 1 wafer or a full cassette of 25.

- Custom Thickness: We can polish down to 100µm or provide thick 1mm+ windows.

In-Stock Sapphire Inventory

We carry standard sizes from 10mm squares up to 8-inch wafers.

| Diameter | Orientation | Thickness | Polish | Application | Link |

|---|---|---|---|---|---|

| 2" (50.8mm) | C-Plane (0001) | 430µm | SSP | GaN / LED | Buy |

| 2" (50.8mm) | R-Plane (1-102) | 430µm | DSP | SOS / RFIC | Buy |

| 4" (100mm) | C-Plane (0001) | 650µm | SSP | Microfluidics | Buy |

| 6" (150mm) | C-Plane (0001) | 1,000µm | DSP | Optical Window | Buy |

| 10x10mm | A-Plane (11-20) | 500µm | DSP | Hybrid Circuits | Buy |

Selecting the Right Orientation

Sapphire is anisotropic, meaning its properties depend on the crystal cut. Choosing the wrong orientation can ruin your epitaxial growth.

1. C-Plane (0001)

The most common orientation. It is chemically stable and has a lattice match suitable for Gallium Nitride (GaN) growth, making it the industry standard for blue/green LEDs and laser diodes.

2. R-Plane (1-102)

Preferred for Silicon-on-Sapphire (SOS) applications. R-plane sapphire allows for the hetero-epitaxial growth of silicon, used in high-speed RFICs and pressure sensors due to its excellent electrical isolation.

3. A-Plane (11-20)

Used for hybrid microelectronic applications requiring a uniform dielectric constant and high insulating characteristics. It is also often used for optical windows where birefringence needs to be minimized along specific axes.

Growth Methods: KY vs. CZ vs. EFG

Not all sapphire is created equal. The growth method determines the defect density and cost.

| Method | Full Name | Characteristics | Best For |

|---|---|---|---|

| KY | Kyropoulos | High optical quality, low defect density. | Large diameter (6"+) LEDs & Optics |

| CZ | Czochralski | Fast growth rate, good for C-axis rods. | Laser rods, smaller substrates |

| EFG | Edge-defined Film-fed | Grows ribbons/tubes/sheets directly. | Cost-effective tubes, specialized shapes |

| HEM | Heat Exchanger | Large boules, good homogeneity. | Large optical windows |

Optical Properties

Sapphire is a rugged optical material with a transmission range from 150nm (UV) to 5500nm (IR). It is extremely hard (Mohs 9), second only to diamond, making it scratch-resistant and ideal for harsh environments.

- Refractive Index: ~1.77 (Visible)

- Thermal Conductivity: ~25 W/m·K (at 100°C) – significantly better than glass.

- Melting Point: 2040°C – survives high-temperature processing where quartz would fail.

🔬 Case Study: Durability & Cleaving

The Challenge: A researcher needed 4" and 6" substrates capable of withstanding:

- High temperatures (up to 200°C).

- Highly alkaline solutions (pH > 12).

- Multiple reworks (stripping photoresist and reusing the wafer).

The Solution: We supplied C-Plane Sapphire. Beyond its chemical inertness, C-Plane is the "softest" orientation relative to others, making it the easiest plane to cleave for downstream processing.

Reference Case #199562