Benefits of Spin-on-Glass

A researcher requested the following quote:

"I'm looking for a spin-on glass (SOG) material that can be spin- coated with a micrometer thickness of (2~5 microns). Can I get this thickness using your product by a single spin-coating or multiple spin-coatings? Is your SOG's refractive index closed to fused silica (quartz) or HSQ?"

coated with a micrometer thickness of (2~5 microns). Can I get this thickness using your product by a single spin-coating or multiple spin-coatings? Is your SOG's refractive index closed to fused silica (quartz) or HSQ?"

Compared to gas diffusion doping, Spin-on doping uniformity is better. The variance across a wafer is between 0.5% and 1% and variance from wafer to wafer ranges between 1% - 2%.

Reference #265115 for specs and pricing. Buy as few as one wafer online and start researching today!

Get Your Quote FAST! Buy Online and Start Researching Today!

Spin On Glass

In addition, there are still many applications of spin-on glass technology, and these applications are gaining the various benefits discussed here. Spin on glass can satisfy new applications and their needs and can form compounds that differ in their chemical composition and properties. The substituents have a high binding energy to silica and dissolve when the spun glass layer is exposed to high temperatures during curing. [Sources: 3, 5]

In addition, the inventive TEOG - TEOS Spin - on glass has an additional advantage: there is no stress - altered flexibility of the glass based on spin. Through experiments, we have found that if processed correctly, the spinning glass described here can overcome the disadvantages mentioned above. In our work, a treated dielectric based on diluted deionized water as a viable solution for producing a powerful, cost-effective, and environmentally friendly spin on glasses.

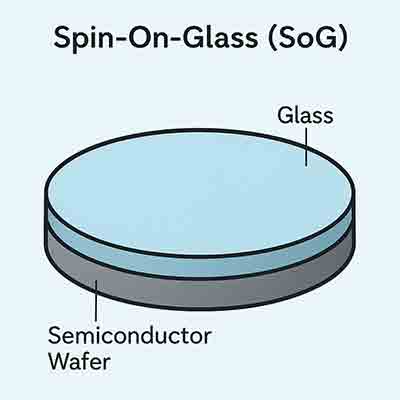

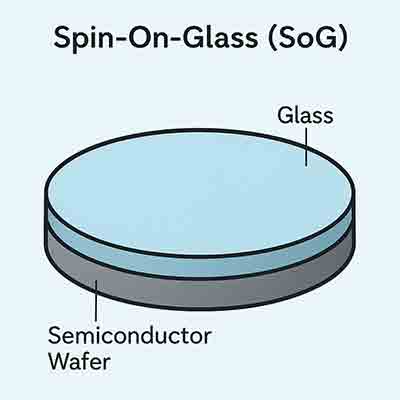

What is SOG?

Video Explaining Spin-on-Glass.

The planarized spin - on glass (SOG) - forms next to the first silicon oxide layer. The high selectivity of etching is crucial to remove the previous etching step and protect the metal from etching. In our work, the suction is applied to a glass layer and the CVD (silicon oxide barrier layer) is slowly etched. At the same time, the "etch recirculation" is carried out using reactive ion etching (RIE) under conditions that etch the SOG at the same speed as the glass layers, but at a much slower rate. [Sources: 1, 4, 8]

Another problem that makes etching - reprocessing - on glass layers more difficult is that the thick spinning film also detaches from the substrate during subsequent processing. Here the spin on glasses can become very thin and is a big step, which is connected with the use of stacked capacitors. Even in the case of a thin layer of etched spun glass, the exposed edges can lead to interlevel shorting and other reliability problems. Another problem that annoys the etch-back process is regions where a significant step is embedded in the underlying substrate, such as on the surface of the glass layer. [Sources: 1, 3]

Spin on glass can become quite thin when using the spin-coater process, especially with thin glass layers. [Sources: 1]

The spin - on glass composition in this invention is stable, even if it is increased to a temperature of more than 1,000 degrees Celsius (3,500 degrees Fahrenheit). The reaction, which lasts two hours or more at ambient temperature, will effectively influence the composition of the glasses. Spin of glass occurs in alloys that are known to be resistant to the effects of high temperatures, such as high pressure, high heat and high humidity. At minus degrees there is no significant effect on the properties of the alloy or on its magnetism, which seems to be practically unused in daily life. [Sources: 2, 3, 7]

The present invention concerns a coating solution using a semiconductor product commonly referred to as spin - on glass composition. This is a liquid silicon mixture that can be applied to the surface of semiconductors on a wafer and then spun to create the coating layer on the top. In this technique, the spin on the glass composition fills the recessed areas of the wafer resulting from various insulating and conductive regions. For example, a spin of glass materials can be either a siloxane - a base material marketed under the trade name accuglass by Allied Signal Corp. - or a glass - a material such as glass. [Sources: 1, 3]

Although the spin on glass as a liquid precursor has a levelling effect, the thickness fluctuates greatly due to the underlying substrate. [Sources: 1, 3]

Spin-on Silicon-Based Dielectrics

One disadvantage of spin on the glass composition is that it cannot control the plasma etching rate or the produced layer, as it is sensitive to the O 2 concentration. This minimises the micro-loading that would otherwise lead to non-flat surfaces that would be created by micro-loading. Although gasification can be eliminated by removing the metal, a number of other problems associated with etching on the back may occur, some of which are normally carried out with a plasma etching device, such as lack of selectivity. [Sources: 1, 3]

Sources:

[0]: https://shibaura.pure.elsevier.com/en/publications/spin-on-glass-film-treatment-technology-using-a-fluoroalkoxysilan

[1]: https://www.google.fr/patents/US5461010

[2]: https://en.wikipedia.org/wiki/Spin_glass

[3]: https://patents.google.com/patent/US5152834A/en

[4]: https://www.freepatentsonline.com/5747381.html

[5]: http://www.google.com/patents/US5910680

[6]: http://www.scielo.org.mx/scielo.php?script=sci_arttext&pid=S0035-001X2016000300282

[7]: https://scitechdaily.com/new-whirling-state-of-matter-discovered-self-induced-spin-glass/

[8]: https://www.google.com.na/patents/US5631197

[9]: https://www.science.gov/topicpages/s/spin-on+glass+sog.html

coated with a micrometer thickness of (2~5 microns). Can I get this thickness using your product by a single spin-coating or multiple spin-coatings? Is your SOG's refractive index closed to fused silica (quartz) or HSQ?"

coated with a micrometer thickness of (2~5 microns). Can I get this thickness using your product by a single spin-coating or multiple spin-coatings? Is your SOG's refractive index closed to fused silica (quartz) or HSQ?"