Blogging for Wafers

Semiconductor Blog Carousel

Get Your Question Answered FAST!

What is Moore's Law?

Moore's law is not a natural law, but one made up to provide future expectation that the density of a microchip will double, on average, every two years. This decreases the chips speed while increasing its performce.

The cost of the chip is miniscule to the designing of the chip architecture. The smaller you go the harder it is to fabricate how the electrons flow and what connects to what.

It's often believed that Moore's Law will soon end. However this seems highly unlikely as engineers are working hard to extend the future of the law.

Silicon Wafer Blog

-

Top Things You Should know About Silicon Wafers

-

Best Silicon Wafer Etching Processes

-

Things You Should Know about Silicon Wafer

-

What is Extreme Ultraviolet Lithography and What Silicon Wafer Specs Do you Use?

-

How do you make Silicon Wafers into Computer Chips

Will Gallium Nitride (GaN) Replace Silicon (Si)?

What is Micropipe Defect Density?

What Silicon Wafer Should I Use for Spin Coating?

What Silicon Wafers are Used To Fabricate Electrodes Used In Lithium Ion Batteries?

What is Sum Frequency Generation, and What Wafers do I Use for Research?

Wafers Used to Fabricate Quantum Cascade Lasers (QCL)?

What Are The Advantage and Disadvantages of MOCVD?

Differences Between Amorphous and Crystalline Solids?

What Silicon Wafers Are Used for Scanning Electron Microscopy (SEM)?

What Silicon Wafers Can Be Used for Helium Beam Research?

Silicon and The Process of Ion Implantation

What Glass Wafers Used for Optical Darkfield Imaging

What Silicon Wafer Should I use to Fabricate Single Electron Transistors?

What Substrate Should I Use for Underwater Solar Energy Generation?

What Silicon Wafers are Used for Anisotropic Wet Etching?

What are Silicon Electronics and What do They Look Like?

What are Silicon Wafer Crystalline Defects?

What are the Pros/Cons of Gallium Arsenide Solar Cells?

How Do Photovoltaics Work?

What is Space Based Semiconductor Chip Fabricaton?

What are the advantages of Silicon Germanium (SiGe) in semiconductor technology?

What Silicon do I Use for Optical Filters in Transmission?

What GaN HEMT Wafers Can I use for Power Applications?

What is the Sheet Resistiance of Graphene on PET Samples?

What is Germanium (Ge)?

How to Grow Zinc Oxide (ZnO) Nanowires with Gold (Au) Coated Silicon Wafers?

What N-type Polysilicon Wafers are Used in MOCVD depositions?

What Silicon Wafers are Used Transmit THz Wavelengths

What Silicon Wafers do I use to Grow Pollen on?

What Float Zone Silicon Wafers for Infrared Spectroscopy Measurements?

What do Silicon Wafer Wells Look Like?

What is the dielectric properties and optical properties of 200mm Sapphire Wafers?

What is Cryogenic Design?

Why Use Highly-Doped Silicon Wafers?

What is the Thermal Behavior of Sapphire Wafer?

What Wafers are used for MEMS Based Acoustic Resonators

What is Black Silicon Wafer Applications?

Advantages and Disadvantages of MOVCD

Silicium Wafers for German Semiconductor Industry

Silicon Carbide Wafer Supplier

Silicon Wafer Materials

What Cassette Should I Use for Substrate Packaging?

What Is A Graphene Sensor?

What Is Barium Titanate (BaTiO₃) Crystal Substrates?

How To Choose The Right Silicon Wafer?

What Electronic Wafers Should Be Used for Research and Production?

What is RCA Cleaning?

Substrates for Semiconductor Engineering

What are Doped Semiconductors?

What are Semiconductor Standards?

Learn About Scratch/Dig on Substrates

What Substrates are Used to Fabricate Film Bulk Acoustic Resonators?

What Substrates Used to Fabricate Nanoparticles?

What Substrates are Used for THz Spectroscopy

What Alpha Quartz Do You Need for Your Research?

What Substrates Are Used Under an Optical Microscope?

Why Ultra-Flat Substrate Surfaces Are Essential for van der Waals Experiments?

What Strontium Titanate (SrTiO3) Wafers are need for Research and Production?

Mohs Hardness of Semiconductor Substrates

Substrates Used in Integrated Circuit Design

All Semiconductor Substrates Listed

What Are III-V Semiconductors?

What Substrates Are Used to Fabricate mmWave Devices?

Where Can I Buy Quartz Boats?

Semiconductor and Wafer Processing Quartz Boats

Photolithography Process

USA Made 200mm 4H Silicon Carbide Silicon Wafers

What's the Imporance of RoHS Standards?

Fluorine-doped Tin Oxide (FTO) Substrate Applications

Semiconductor Equipment

What Substrates Are Used to Fabricate Pyroelectric Detectors?

Unleashing Nanofabrication: Best Silicon Wafers Revealed

Affordable Sapphire Wafers: Powering Optoelectronic Innovations

Comparing SOI Wafers: 150mm vs 200mm

Understanding Raman Spectroscopy for Material Analysis

Revolutionizing Photonics: Top Silicon Wafers for Advanced Applications

Illuminating Choices: Silicon Wafers for Light Tech

Silicon vs. Sapphire Wafers for Optoelectronics

Revolutionizing Photonics: Top Silicon Wafers for Advanced Applications

What Substrates Are Used For Polaritonic Research?

What are Polar Materials Substrates?

What Substrates Are Used to Fabricate Visible-Light Communications Systems?

What are the Wafer Manufacturing Steps?

Best Silicon Wafer Specs to Fabricate Cutting-Edge Electronics

What Substrates Are Used to Fabricate Amorphous Transistors?

Substrates Used To Fabricate Actuators

What Are Reclaimed Silicon Wafers?

Diamond Semiconductor Substrate Advantages

Sapphire Substrates used to Fabricate LED Sensors

4H Silicon Carbide Substrates for Ev Power

FC-BGA vs. FC-CSP: Choosing the Right IC Substrate for AI, 5G, and HPC Packaging

From Lab to Fab: Why Engineers Choose III-V Substrates

Why GaN is Challenging Silicon in the Semiconductor World?

Unlocking Microelectronics: Best Silicon Wafers for Research

Revolutionizing Industries: Top 5 Applications For Silicon Carbide Wafers

Unveiling the Marvels of Ultra-Thin Silicon Wafers

Revolutionizing Solar Cells with Epitaxial Wafers

Revolutionary MEMS Sensors Transforming Industrial Applications

Silicon Carbide Wafers for Extreme Heat: Powering High-Temperature Electronics

Unlocking Power: Silicon Carbide Wafers in Electronics

Mastering Sapphire Wafer Maintenance for Long-Lasting Performance

Sapphire Wafers: Powering High-Frequency Electronics

Revolutionizing MEMS with Innovative Thin Films

Maximizing the Use of Silicon Wafers in MEMS Technology

Learn About Ultra-Thin Silicon Wafer Technology

How to Choose Custom Wafer Sizes: A Comprehensive Guide

Optimize Your Research with SIMOX Wafers

Popular Silicon Wafer Variations for Microelectronics

Best Techniques For Etching Silicon Wafers

Lithography Techniques For Silicon Wafers: Advanced Processes for Semiconductor Manufacturing

Best Practices For Handling Silicon Wafers

Doped Vs Undoped Silicon Wafers: A Comprehensive Comparison

Best Thermal Oxide Deposition Techniques for Silicon Wafers

Substrates Used to Fabricate Quantum Transistors

Substrates Used With Polypyrrole

Diamond-Like Carbon (DLC) Coatings on Silicon Wafers: Applications in Semiconductor Fabrication

Substrates Used for Dielecrtric Metasurfaces

Substrates Used to Fabricate Power Electronics

Wafers Used to Fabricate Nanopore Membranes

Silicon Wafers Used to Fabricate Photovoltaics

Silicon Carbide Substrate Manufacturing

Silicon Carbide vs Silicon Wafer Performance/Price

What are the Benifits of Silicon-on-Insulator Performance?

Choosing The Correct SOI Wafer Specs

SOI Wafers for Microelectronics

Silicon-On-Insulator Used To Fabricate Integrated Circuits

SOI Tech Used to Fabricate MEMS Devices

Silicon-on-Insulator (SOI) Research Guide

Comparing Silicon Wafer Types

Quartz Substrates for Precision Timing Technologies: MEMS, Quartz & Atomic Solutions

What Substrates Are Used to Fabricate MEMS Based Audio for Earbuds?

What Is Space Based Manufacturing?

Applications of Optical-Grade Lithium Niobate Wafers

How To Maximize Silicon Wafer and Other Substrate Polishing

Lithium Tantalate Substrate Applications

Customized Lithium Niobate (LiNbO₃) Substrates — Applications & Specifications

Discover Applications of Lithium Niobate (LiNbO₃) in Photonics

How to Choose the Correct LiNbO3 Substrate for Your Application

How to Choose The Right Lithium Tantalate Wafers for Your Application

Discover the Best Lithium Niobate Wafer

What are Lithium Niobate Wafer Sizes?

What GaN on Sapphire Substrate is Right for My Research?

Learn about Anistropic Etching of Silicon Wafers

Empowering Researchers with Precision Semiconductor and Dielectric Substrates

What Silicon Substrates are used for Aerospace Efficiency

What Substrates For Organic Photovoltaics Solar Cell Research?

What is a Technical Datasheet?

What Substrates Are Used To Fabricate Flexible Electronics?

Lithium Niobate Substrates for Advanced Nonlinear Optics

What Substrates Used in Attenuated Total Reflectance (ATR)?

Best Lithium Niobate Substrates for Non-linear Optics

Lithium Tantalate Properties for RF Applications

How To Polish Lithium Niobate Wafers

Lithium Niobate SAW Wafers

What are SAW Device Applications?

Lithium Tantalate Substrate Applications

What are SAW Integration Best Practices?

Thin Film LiNbO3 Substrates

Where Can You Buy 12 Inch Silicon Carbide Wafers?

Whate Is The Silicon Wafer Price and Other Substrates In India?

What SiO2 thickness on Silicon substrates is the best for growing 2D materials?

What Gelpak Do I Need For Packaging My Wafers?

What Graphene Specification Are Required To Fabricate Graphene Sensors?

What LiNbO3 Specs Are Used To Fabricate SAW Delay Lines?

What Dry Thermal Oxide on Glass Specs Do I Need for Nanorod Fabrication?

What Gallium Arsenide Wafers Are Suitable for Eeducational Laboratory Testing Of Photovoltaic Cells?

What Is The Difference Between Siicon-vs-Silicone

What Is the Most Economical Silicon Wafers used To Fabricate Integrated Circuits and Electronic Components?

Where Can a Research Go To Purchased Wafers and Receive Wafer Services?

What Is The Most Common Substrate To Fabricate Silicon-on-Chips(SoC)?

The Silicon Bohr Model: A Simple Way to Understand Complex Semiconductor Physics

Etching Silicon Wafers to Fabricate Micro-Planar Heat Pipes

What Silicon Wafer and Other Substrate Services Do You Provide?

What Substrate Specs Do You Need To Fabricare Nanochips?

How Do You Prepare Silicon Carrier Wafers for Reactive-Ion Etching?

Vertical Gallium Nitride Substrates

What are Structure of Schottky Barrier Diodes?

What Wafers used for Reactive-Ion Etching?

What is Crystalline Silicon (C-Si)?

What ZnSe Wafers Are Used For Testing X-Ray Electron Spectroscopy?

InGaP Thin Film Substrate for Photonic Metasurfaces

Best Doping Techniques for Silicon Wafers: Diffusion, Ion Implantation & More

P-Type vs N-Type Silicon Wafers: How to Choose the Right Substrate for Your Device

Silicon Wafer Doping Techniques Compared: P-Type, N-Type, Undoped, and Process Choices Explained

Ultra-Thin vs Standard Silicon Wafers: Which Is Right for Your Next Device?

Innovative Substrate Solutions for MEMS: From Silicon to Advanced Materials

How To Choose Wafer Characterization Equipment

Choosing the Ideal Silicon Wafer for Semiconductor Devices

Silicon Wafer Thickness Standards Explained

Ultra-Thin Silicon Wafers Explained

Diamond-Coated Wafers for Advanced Thermal Management in AI and Power Chips

What is Wafer Level Packaging?

What Substrates Are Used for NanoSIMS applications?

Silicon Wafers Used for Prototyping

What Are High-Quality Silicon Wafers

What Is The Importance of Silicon Wafer Resistivity?

Why Use Czochralski Grown Silicon Wafers?

Boron vs. Arsenic Doped Silicon Wafers

What Are Silicon-on-Sapphire Wafer Applications?

What Are Bare Silicon Wafers Used For?

Barium Flouride Substrates for IR Applications

What Silicon Wafer Specs Are UsedTo Fabricate Computer Chips?

What is a Periodic Table?

Thermal Oxide Used for Optical Coating Research

What is Kerf Waste in Semiconductors?

What Silicon Wafer Spec Is Used for Bonding?

Importance of Silicon Diameters

Different Substrate Diameters Explained

What Is The Difference Between Prime and Test Grade Silicon Substrates?

What Substrate Specs Are Used to Fabricate Optical Sensors?

What are Thin Solid Films?

SOI vs Bulk Silicon Wafer Performance

Choosing The Correct Silicon Diameter

Difference Between 100mm and 150mm Silicon Wafers

Why Choose 150mm Silicon Wafers for Higher Throughput and Lower Risk?

The Difference Between Float Zone and Cz Silicon Wafers

What Prime-Grade-Silicon-Wafers Should You Use For Device-Testing

Why Are Double-Sided Polished Silicon Wafers Used In Optics

4h Silicon Carbide Prime Grade vs Test Grade Substrate

What Gallium Arsenide Substrates Used For Photonics Research

What Indium Antimonide Substrates are used for IR Sensing MWIR Detectors

What Lithium Niobate Wafer Specs are used for Next-Generation Optical Modulators?

What Sapphire Wafers Are Used For?

What Is The Price of Electrostatic Wafer Chucks?

Optimizing 2D Material Growth: Selecting Substrates for Graphene and TMD Nanosheets

We have the blogs to help answer your questions!

We can answer any substrate question! Just ask!

Silicon Wafer Blog

Top Things You Should Know About Silicon Wafers

How to Pick Silicon Wafers for Electronics Fabrication?

Modern Dicing Techniques for Advanced Materials

What Quality Assurance Standards Are There for Semiconductor Substrates?

Choosing The Correct Silicon Carbide Substrates for Your Research

Optimizing Wafer Testing

Silicon-on-Insulator Wafers Vs. Conventional Substrates

Epitaxial vs. Standard Silicon Wafers: A Complete Guide

Guide to Plasmonics and Photonics Wafers

Choosing Semiconductor Materials: A Comprehensive Guide

What is Optical Grade Silicon?

What Are Bonded Silicon on Insulator Layers on Your Capacitors?

Top Things You Should know About Silicon Wafers

What are Coin Roll Silicon Wafers?

What is Multicrystalline Silicon?

What is X-Ray Diffraction?

What is Dislocation Density?

What is Molecular Beam Epitaxy (MBE)?

Silicon Fabrication Methods

Can Graphene be Used In Making Airplanes?

Best Silicon Wafer Etching Processes

Things You Should Know about Silicon Wafer

Things You Should Know about Silicon Wafer

How do you make Silicon Wafers into Computer Chips

Will Gallium Nitride (GaN) Replace Silicon (Si)?

What is Micropipe Defect Density?

Why are Silicon wafers Round?

Why is Silicon a Widely Used Semiconductor?

Why Graphene Processors are needed for Quantum Computers

Why is it so hard and hence expensive to control the TTV under 0.5 µm?

What is the Density of Silicon?

How Many Silicon Solar Panels Needed to Power The World!?

What Silicon Wafer Spec Would you Use for Research and Development of Inkjet Printers?

III-V Substrates Will Dramatically Change Cloud Storage for Greater Profits

Is the Composition of Silicon Germanium (SiGe) Conrollable?

Why are Microchips Made from Silicon?

What is Graphene Used In?

How Fast Is Gallium Nitride (GaN) Semiconductor Device Market Growing?

Can Gallium Nitride UV Devices Help Mitigate COVID-19 and Other Viruses?

What Silicon Wafer Specs Should I Use Femtosecond Spectroscopy?

What Silicon Carbide (SiC) Wafer should i use for a van der Pauw sensor?

When Will Silicon Carbide (SiC) Replace Silicon (Si) in Power Electronics

Can you Deposit Metal Films on Sapphire?

What Is A Semiconductor and Why Should You Care?

Graphene Deposited on Silicon for the First Time Will Result in Faster, Low Power Semiconductors

Where Can I Learn About Silicon & Semiconductors?

What is the difference between Research and Prime Grade Silicon Carbide (SiC) Wafers?

Do you offer glass wafers that are infrared compatible?

The Truth About Bulk Semiconductor Crystals

What Silicon Wafer Should I Use for Micro-Machine Waveguides?

What is the Shockley Queisser Limit

What is Photonics-based Computing?

Where Can You Find InGaP Substrates?

Can GaN Substrates Make Ultraviolet LEDs to Fight The Covid-19 Virus

GaN Epitaxy Wafers to Combat Corovirus using UVC LEDs

How to Prepare Silicon Wafers

A Quick Overview of Silicon-on-Insulator Fabrication

How to Pick a Silicon Wafer Supplier

How to Make a Computer Chip

Why is Gettering Important to Wafer Fabrication?

Float Zone (FZ) Silicon Wafer Facts

Advantages and Disadvantages of Gallium Arsenide Solar Cells

Will Silicon Chiplets to Replace Traditional Mother Boards?

What Wafers are used in Quartz Crystal Microbalance (QCM) Sensors?

Silicon Microphone Defined

What are HRFZ Silicon Wafers?

What Silicon Wafer Spec Should I use?

Thin Thermal Oxide on Silicon to Fabricate One Atom Thick Transistors

1.2 Trillion Transistors on a 12 Inch Silicon Wafer

What is Scanning Tunneling Microscopy?

What Is An Optical Resonator?

C-Si Wafers Used for Hologram Research

What Sapphire Wafers Are Used for Oil Immersion-Microscopy?

What Wafers are used to Calibrate Film Thicknesses?

Why are Silicon Carbide (SiC) Better than Sapphire and Glass for Bonding with Silicon?

What Carrier Wafers are Used in Plasma Etch Systems?

What GaN Specs are Used for RF Schottky Barrier Diode application (SBD)?

What are high-power RF Avalanche Transit Time diode?

What is Silicon's Refractive Index?

How to Measure Silicon Wafer Resistivity Using Four Point Probe?

What Silicon Wafers are Used to Fabricate Internet of Things (IoT) Devices?

How do you Prepare Silicon Wafers for Reactive-Ion Etching (RIE)?

What is a Compound Semiconductor?

How to Model Calibration of Poly Si Thin Film Growth?

What are Nanochip?

What is Electrochemical Atomic Layer Deposition (ALD)?

What are Nanocomposite?

What Wafer Spec are Use to Fabricate Membrane-Based Nanocalorimeter Devices?

What Are Silicon Nitride Wafer Uses?

What is A-Axis Sapphire?

Challenges in Testing and Characterizing Silicon Photonic Devices

What is a SiC Wafer?

What is a MOSFET?

What is CMOS?

What Threatens Moore's Law?

What is the Difference Between Borosilicate and Soda Lime Glass?

What is a MOCVD Reactor?

Does Adding Carbon to Silicon Monocrystalline Lower the Melting Point?

What is Difference Between Monocrystalline and Polycrystalline Solar Panels?

What is the Difference Between LPCVD and PECVD?

Can We Turn an Electronic Chip Into a Photonic One?

What is Carrier Concentration?

What Silicon Wafers are used for Integrated Passive Device (IPD)?

What are The Uses of The Piezoelectric Effect?

How safe is it to work in a semiconductor fab?

What is Vicinal Silicon?

What is the Role of a Silicon Validation Engineer?

What Are The Differences Between Planar and Pattern Film Wafers

What is Photoresist?

Silicon Wafer Carrier Mobility

What is a Silicon Boule?

How Microchips Are Made?

What is Van Der Waals Epitaxy?

What is Anistropic Silicon?

Silicon Wafers for Thin-Film Transistor Research

How Do you Design Integrated Circuits?

What is Lithography?

What is the Difference Between Borophene Vs Graphene?

What Is Micro Electromechanical Systems (MEMS)?

What Is Magnesium Oxide (MgO) Wafers?

What is Parametric Test in Semiconductor Manufacturing?

What are Microfluidic Devices?

What is Semiconductor Spectroscopy?

What are Photonic Applications?

What is Lab-on-a-Chip?

What Substrates/Wafers are used to Fabricate Multilayer Surface Acoustic Wave (SAW) Devices?

What is NMOS Transistor?

What is Anti-reflection (AR) Coating?

Wafers Used in Millimeter-Wave Photoconductive Switches

What (643) Oriented Silicon Wafers are used for Epitaxial Electro-deposition Research

What is the Infrared transmission of Silicon Wafer?

What Wafers are Used for THz Applications?

What Is Orthotropic Mechanical Properties in Wafer Plane?

4 Inch Silicon Wafers Used for Mesoporous Silicon Nanoparticle

What is HF Galvanostatic Charging?

What Turns On and Off a Hall Effect Reed Switch?

What are Types of Semiconductor Lasers and Their Applications?

What is Wafer Scale Testing?

What is High Refractive Index Glass?

What is Macroporous Silicon?

What is Sapphire's Surface Microroughness?

What are Miller Indices?

How Do You Test a Polaris Hall Effect Sensor?

What is Graphyne?

What is a Silicon Bolometer and How Do You Use It?

What is a Darlington Transistor?

How to Fabricate a Silicon Readout IC

What is Open and Closed Channel Microfluidics?

What are Recent Advances in Photonic Crystals

What Substrates are Used for Microreactor Array Device Research?

What are The Advantages of a Silicon Carbide MOSFET

Why is a Silicon Semiconductor Used in a Thermistor?

What are Acoustic Wave (SAW) Applications?

Surface Acoustic Waves for Dual Biosensors for Cancer Cell Detection

What is Atomic Layer Deposition (ALD)?

What is Electron Beam Evaporation?

What are Graphene Electronics?

What are Right Handed and Left Handed Quartz?

What is Amorphous Silicon?

What is Crystalline Silicon?

What are Silicon Biosensors?

What are Silicon Modulators?

What is Microscopy Imaging?

What is the Optical Or Stress Data for Sputtering Silicon Wafers?

What is UV Lithography?

What is Mesa Etching?

What Are the Challenges and Limitations in Semiconductors and Nanophotonics?

Where can I find Silicon Backgrinding Service?

What are the Differences Between Between Intrinsic & Extrinsic Semiconductors?

What does an Organic Transistor Look Like?

Understanding Failure Analysis in Semiconductor Synthesis and Defect Science

Silicon Carbide (SiC) Space Based Radiation Detector

What is the Surface Finish of Silicon Substrates?

What Types Of Silicon Transistors Are Available?

What is 3C Silicon Carbide?

What Is the Width of the Base Region in a Transistor?

What is Dry Etching in Semiconductors?

What are Epitaxial Structure Processes?

What are Five Development Trends of Photovoltaic High-Frequency Inverters?

Can you 3D Print Semiconductor Devices?

What is SU-8 Lithography?

What are Silicon Nanowires (SiNWs)?

What is SU-8 Photolithography?

What Material Will Replace Silicon?

What is Condensed Matter?

What is Swept Quartz?

Is Gallium Nitride More Efficient than Silicon?

How Do You Measure Wafer Uniformity?

What are the Advantages and Disadvantages of Silicon and Germanium Diodes?

What is KOH Etching?

What is a Rocking Curve?

What is Wafer Level Packaging?

What does SAW Grade mean?

What are Silicon Wafer Pressure Sensors?

What are NAND Wafers?

What is a Wafer Plate?

What is UV Grade Sapphire Window?

What is Lithium Niobate Thin Film?

How Large Can a Single Sheet of Graphene Be?

What Wafers are Used for Ring Resonator Research?

What is Materials Science Engineering?

What is a Silicon Dioxide Wafer?

What do Device Research Labs Do?

What is Poly Silicon Carbide (SiC)?

Silicon Wafers Used Transmission Infrared Spectroscopy (TIES)

What Is a Semiconductor Engineer?

How Are Silicon Wafers Measured to Be a Centimeter Long?

What Substrate is Used to Fabricate Wearable Sensors?

What is a Four Point Probe?

Which N-Doped Silicon Wafer Has the Highest Electric Conductivity?

What is a Silicon Filter?

What is a Silicon Membrane?

What is Electron Beam Lithography?

What Wafers are Used in Single Particle Spectroscopy?

What is Dielectric Behavior?

What is a Transmission Electron Microscope?

What Types of Chips Made of Silicon Carbide?

What is Silicon Lattice Constant?

What is Graphene Used For?

Will Graphene Change the Future?

What is Spectroscopy?

What is Holding Back Graphene Mass Adoption?

What are Zinc Selenide (ZnSe) Applications?

What Are the Advantages and Disadvantages of Silicon Solar Cells?

Why is Silicon Used in a Solar Cell?

What are Ceramic Wafers?

What are he Best Semiconductor and Electronics Companies in the World

How do you determine the cost of a Silicon Wafer?

What are The Benefits of Calcium Fluoride Wafers?

Understanding the Thermal Properties of SiliconUnderstanding the Thermal Properties of Silicon

What is Silicon on Glass (SoG) Wafers?

What Glass Substrates Should You Use in Your Device Research?

What is Wafer Fabrication?

How Much Does a Silicon Wafer Cost?

What is Silicon resistivity?

What is Silicon Oxide?

What Substrates are Used to Fabricate Thin Film Solar Panels?

What is Black Lithium Niobate?

What is Silicon Epitaxy?

What are Magnesium Doped Wafers Used For?

What Are Epitaxially Grown Devices?

What Are Semiconductor Devices?

How do you Polish Subrates using Chemical Mechanical Polishing?

What is a Silicon Photodetector?

What Substrates are used for Far-IR Transmission Experiments?

Substrate Recommended for Mid-Infrared Transparency

Confused as to which specification you need for your research? We have engineers that can help you!

Stacking Gallium Nitride & Silicon Transistors On Silicon Wafers

How UniversityWafer Helps Medical Research?

We are very active in the medical research field. We provide the highest quality, lowest cost substrates for the following:

Graphene Based Sensors

University of Illinois researchers have used our silicon wafers with thermal oxide to fabricate a micrometer-size graphene-based sensor to measure oxygen permeation through pulmonary membranes.

Biosensors to Detect Proteins in Saliva

Borofloat (33) glass substrates coated with a thin film of chrome, gold and titanium to fabricate an IDE pattern used to develop an interdigitated electrode sensor platform targeting the Plasmodium falciparum Histidine Rich Protein 2 (PfHRP2) protein in saliva samples.

Remodeling Cytoskeletons

Polished silicon wafers were used to determine if cells cultured in a 3 Dimensional (3D) matrix have a softening behavior and to link it to cytoskeletal remodeling.

Micro-Droplets for Cell Encapsulation

Biosample encapsulation using droplet microfluidics technique using 4 inch silicon wafers to fabcricate a photomask to generate micrometer sized emulsions within microchannels.

Silicon Nitride Wafers Used in Nanopore Sensing Device for DNA Detection

Researchers have used a thin nitride membrane will seperate two buffers. One buffer will contain DNA. There will be a single pore in the membrane. When applying a bias across the pore, DNA will begin to translocate and we can detect them by the drop in current.

Silicon wafers will be used as the substrate upon which we can deposit silicon nitride. Ultimately, the silicon will be etched away, leaving only the nitride membrane.

The following bare wafer was used. UniversityWafer, Inc. then deposited the nitride.

Item# 2345 Silicon 100mm P /B <100> 1-20 300um DSP

Fabricating 4 inch 500nm Crystalline Gallium Phosphide (GaP) Film on ~500um Quartz

To grow monocrystalline GaP 500nm thick, you need to grow it on a substrate that is lattice matched to GaP. Both Quartz and Sapphire are far away from that.

By MOCVD, one can grow GaP on Silicon (Si) - Lattice constants are GaP: 0.54505nm, Si: 0.54310nm. The cost would be about $2,000 for 500nm of GaP on 2"Ø Si wafer.

If your objective is to grow GaP on an insulator then consider growing it on high resistivity Silicon with Ro > 20KOhmcm.

Another possibility is to grow Thermal Oxide (SiO2) on a Silicon wafer and then GaP on SiO2.

Thermal Oxide is close to being monocrystalline and so maintains the lattice spacing of Si, that is 0.54310. This is in contrast to Quartz which exhibits Lattice constants of 0.49137 and0.54050.

I dare not estimate the cost of GaP/SiO2/Si because I do not know of a facility that has actually achieved such Epi growth Theoretically it is possible and chances are that it can be done.

Likely I can get an MOCVD facility to take it on but only as a "best effort" research project.

Graphene-Based Device Research

As you probably know we grow graphene in our reactor via Chemical Vapour Deposition (CVD) method. We use a 18μm thick copper foil as catalyst and methane as a carbon source. We usually use a ferric chloride solution to etch the copper foil and we use a PMMA assisted WET transfer process to transfer the graphene film onto the final substrate.

Please, find attached the TDS for "Graphenea Monolayer Graphene film on various substrates" and the Raman spectra of one of our batches.

We also produce Graphene Oxides by chemical exfoliation of graphite stone. We use our patented modification of the Hummer's method.

Please request the spec sheets 253557.

Alumina Wafers for HDPCVD Cleaning Application

Research client asks: Do you have 4" single flat ceramic alumina wafers? I've got a HDPCVD cleaning application that I think needs alumina dummy wafers?

UniversityWafer, Inc. Quoted:

Roughness(Polished): Ra 0.02~0.05nm

Cut one flat: 32mm ±2.0mm

How Silicon Wafers are used to grow Nanotubes

Nano-systems technologies present the pathway to the future. This is due to the ability of such systems to address the inefficiencies evident in the currently existing technologies. Researchers are laboring towards addressing the challenge of power consumption required by electronic devices. There is a general requirement of powerful devices that use limited power. Currently, all the possibilities have been explored thus necessitating new technologies altogether. Another inefficiency that has to be addressed is the memory issue, where minute devices are needed that can hold more and more information compared to the existing devices. Other challenges are computing power and connectivity. To build nanotubes, we have to apply new and emerging technologies.

Carbon nanotubes (CNTs) are formed by rolling a sheet of graphene forming a nanocylinder that has a diameter of one, one and a half nanometers. The nanocylinders can then be combined in tens of thousands within a specified diameter. Given that they are really small, Carbon nanotube field-effect transistors (CNFET) can be made from them. The transistor does operate similarly to the silicon transistor. Silicon transistors can be converted to carbon nanotube field-effect transistors by replacing the silicon with carbon nanotubes.

The current technologies use two-dimensional chips. Given that data has to be accessed one bit at a time, the approach is considered to be relatively slow. Better results can be obtained by stacking chips together. Two-dimensional substrates are physically stacked together with two-dimensional chips. Through silicon vias (TSVs) glue the different two-dimensional chips and wafers to each other. The TSVs are characterized as to be large and sparsely arranged. In simple terms, monolithic three-dimensional integration is achieved when different layers are built over each other on the same stirring substrate. No form of bonding is needed while carrying out the process. Monolithic integration is advantageous as it allows one to use nanoscale interlayer vias (ILVs) that currently exist in metal wires in chips today to connect all the different vertical layers.

Fabricating a silicon transistor requires way too high temperatures of about 1100 degrees Celsius to 1200 degrees Celsius. With this, it is impractical to stack silicon layers on top of the existing layer as the layer’s underneath would melt before the next layers have been built. With the new technology on nanotechnology, carbon nanotubes can be made at temperatures below two hundred degrees Celsius. There also exists a variety of memories where one can select from i.e. RRAM, CBRAM, STTMRAM.

Silicon wafers are used as the main basic bottom layer since it is fully compatible with the existing processing and design infrastructure. Also, silicon involves much processing in its fabrication process. The next process involves building metal wires as often as needed. After about three layers, the fourth layer can be made of carbon nanotube transistors. The result is a computer that can do several things. We begin with establishing a layer of memory circuitry, then we build accelerators that aid in supporting the chips embedded computing. After having layers of metal wires, we can have a layer of Carbon nanotubes. This new technology results in increased functionality as they can accommodate the incorporation of sensors such as gas sensors to be embedded in the chip.

With today's need for embedded computing and machine learning, large chunks of information have to be captured from the outside world and interpreted for out good. Also, new ways have to be found in handling activities such as medical screening and testing procedures that necessitate nanotechnology. A study on nanotubes is key to the future.

Consumer Products that use Silicon Wafers

Electronic products that are bought by the consumer for use at a personal level are broadly classified as electronic consumer products. These products have to be physically present and do possess an integration feature to the current technology allowing for interaction with the user in a simple way. Microwaves, television, electric iron box, cellphones, and audio systems are examples of such products. The products use microelectronics integrated with the recent technology to meet the expected functionality. Even though the products may appear simple by physical appearance, they are rather complex in their underlying system. Besides, these products do not provide a few clues about the product itself or its operation (Jasper van Kuijk, 2017). The components that make consumer products may be grouped into three classes i.e. the core product, the extended product, and lastly the symbiotic elements. The picture below illustrates the three categorization classes of a consumer product.

![]()

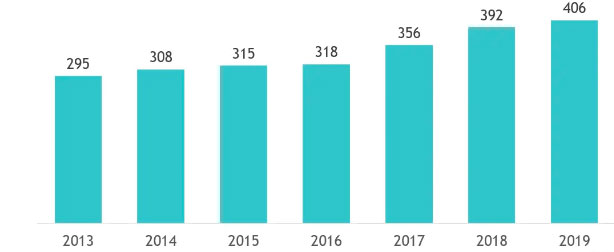

Semiconductor materials used in making electronic devices are made using silicon wafers. In appearance, the wafers are made to be extremely flat disk-shaped, and mirror surfaced. Wafers can be categorized as the flattest items in the world as they are free from miniature surface irregularities. Since the 1960s silicon has been a reliable raw material choice in the manufacture of semiconductors. To date, about ninety-five percent of the devices that are existing in the market are made out of silicon. The worldwide wafer market for the year 2019 was estimated to stand at $9.85 billion and is expected to grow by $3.79 billion by the year 2025 (Contello, 2020). Semiconductors have been the building block of the current modern technology.

The current trend today is that the desire for electronic devices that are comparatively smaller, improved functionality, and faster than the ones existing today. This thus necessitates that the devices should be able to hold a higher number of transistors to aid it support additional features such as wireless computing. Miniaturization has further been propelled by the need for more compact electronics by the market. The ever-changing technology is availing alternatives to silicon though for a few applications. Despite the advancements, silicon still dominates. Integrated circuits used to power computers, microwaves, refrigerators, meters, or phones among other devices essentially use silicon. Consumer products such as virtual reality kits, drones, and smartwatches are predicted to be some of the key products that will expand the market for silicon wafers (Contello, 2020).

Different regions are trying hard to dominate the respective markets despite the existing hurdles. The Asia Pacific region tops the list of the largest market. With support from the respective administrations, the silicon wafer market is expected to have an upward trend. With the advent of the 5G technology, silicon wafer production is expected to increase to meet the expected high demand for smartphones supporting the 5G network. The new technology in place provides an opportunity for the entry of new consumer products thus there is a need for the development and improvement of the silicon wafer production. Firms are now restructuring their operations and focusing on specialization on specific wafer size diameters to have a competitive edge over their counterparts (Contello, 2020).

To convert a silicon crystal ingot to a wafer with the required quality standards, various processes have to be done. First, the single-crystal ingot has to be divided to form thin disk-shaped wafers. Then the edges of the wafer are profiled. The third process involves lapping or grinding to flatten the wafer surface. Then a chemical process is used to eliminate the processing damage existing on the wafer while minimizing mechanical damage. Next, a rough polishing operation has to follow to achieve a mirror surface on the wafer surface. A fine polishing process follows the rough polishing one to get the final mirror surface. Lastly, cleaning process is done to flush out unwanted material from the surface of the wafer (Z.J. Pei a, 2001). The picture below provides a summary of the whole process.

![]()

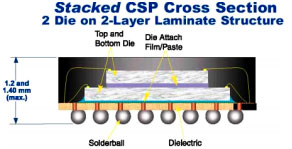

The high integration densities plus the requirement for miniaturization in consumer electronics has resulted in the discovery of chip stacking concept in three dimensions. Specialized packages for the three-dimensional chips have been developed by suppliers in the semiconductor industry. The concept of chip stacking is mostly applicable in memory devices or volume applications desiring high packing densities (Niklaus, 2002).

Companies dealing with consumer products continue to make noticeable steps on to new technology as they constantly are engaged in research. A particular company is Motorola that admits that silicon substrate wafers do offer robustness, high speed, good optical capabilities plus being cheap. This will boost high-speed communication and reduce the cost of microprocessor systems inclusive of optoelectronics and the monolithic incorporation of electronics. Other consumer devices such as DVD players are among the products projected to improve with such important discoveries (Motorola, 2001). With these technologies, the company can make integrated semiconductor circuits or Opto devices on a given wafer.

Last year the Singapore-MIT alliance for research and technology made it public that they had successfully found out how to incorporate silicon III-V in their designs. The current challenge with 5G mobile devices is that their processors are silicon-based CMOS chips that do have low efficiency and generate excess heat. This makes the devices to overheat shutting down the device after a few minutes. Also, in the same year, On Semiconductors did make an agreement with Cree Inc where Cree is to produce silicon carbide wafers and supply it to On Semiconductors. The figure below shows a summary of how consumer electronic demand steadily rises each year.