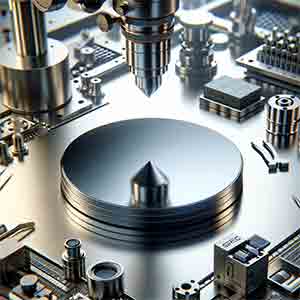

I am doing AFM experiments for capturing ARP 2/3 images. I am using mica as my substrate but results are not up to the mark. I want to apply silicon wafer as my substrate instead of mica. Can I use it? What kind of silicon wafer I have to use?

Using Silicon instead of Mica for AFM

An university engineer PhD candidate requested help with the following:

Reference #279062 for specs and pricing.

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

Mica/Silicon for use in both XRD and AFM Tests

A PhD student requested help with the following:

I want to use a silicon wafer for XRD measurements of polymer coatings. I am not sure which type of silicon wafer is suitable for this. Could you please give me feedback about this?

I need a silicon/mica warfare to use in both XRD and AFM tests. The

sizes are not that much important for now. Could you please send me

UniversityWafer, Inc. Quoted:

32mm P/B [100-9° towards[001] 2,000 ±50um SSP >10 ohm-cm Zero X-Ray Diffraction plate, with central sample pocket 5mmØ×200μm, NO Flats

Reference #262890 for specs and pricing.

This price is only for one wafer? And may I use it also for AFM? If it is only one wafer, do you have cheaper options?

[Q] This price is only for one wafer?

[A] Yes, it is, but item #8215 is a special wafer that guarantees Zero X-Ray Diffraction.

[Q] And may I use it also for AFM?

[A] Yes, you can.

[Q] If it is only one wafer, do you have cheaper options?

[A] We have many, but only #8215 is Zero X-Ray Diffraction. Some cheaper wafers are availble.

Related AFM Substrates and Characterization Resources

Why is Mica Commonly Used for AFM?

Mica is commonly used as a substrate in Atomic Force Microscopy (AFM) experiments. There are several reasons for its popularity:

-

Smoothness: Mica has a very smooth surface at the atomic level. This is crucial for high-resolution AFM

imaging, as it minimizes background noise and allows for clearer imaging of the sample.

imaging, as it minimizes background noise and allows for clearer imaging of the sample. -

Cleavability: Mica can be easily cleaved to produce fresh, clean surfaces. This is particularly useful in experiments where a pristine surface is required.

-

Chemical Stability: Mica is chemically inert for the most part, which means it doesn't react with the samples or the environment, maintaining the integrity of the experiment.

-

Biocompatibility: For biological samples, mica's biocompatible nature makes it a suitable substrate as it does not typically interfere with the biological processes being studied.

-

Flatness: The inherent flatness of mica helps in obtaining uniform sample deposition, which is essential for consistent and reliable AFM measurements.

However, despite these advantages, there can be limitations to using mica, depending on the specific requirements of the experiment. For instance, mica's insulating properties might not be suitable for conducting AFM modes that require a conductive substrate. In such cases, alternatives like silicon wafers, gold films, or other specialized substrates might be used. The choice of substrate often depends on the specific characteristics of the sample being studied and the details of the experimental setup.

Why Use Silicon Substrates instead of Mica for AFM

Atomic Force Microscopy (AFM) is a sophisticated technique used for imaging surfaces at the nanoscale, and it's great to hear that you're using it to study ARP 2/3 complexes. Your substrate choice can indeed have a significant impact on the quality of the images you obtain.

Switching from mica to silicon wafer as your substrate could potentially offer some advantages, depending on your specific experimental requirements. Here are some considerations for using silicon wafers in AFM experiments:

-

Surface Smoothness: Silicon wafers are known for their ultra-smooth surfaces, which is crucial for high-resolution AFM imaging. Ensure that the wafer surface is as flat and defect-free as possible.

-

Type of Silicon Wafer: You should choose a type of silicon wafer based on your experimental needs. For instance, consider whether you need a conductive or non-conductive surface, as silicon wafers can be doped to modify their electrical properties.

-

Surface Treatment: The surface chemistry of silicon wafers can be altered to suit your needs. For instance, you might need to modify the surface to enhance the binding of ARP 2/3 complexes. This can be done through various chemical treatments or coatings.

-

Crystal Orientation: Silicon wafers come in different crystal orientations (e.g., <100>, <111>). The orientation can affect the surface properties, so choose one that best suits your experiment.

-

Cleanliness: Before use, ensure the wafer is properly cleaned and free of contaminants, as these can interfere with AFM imaging.

-

Compatibility with AFM Setup: Check that the size and thickness of the silicon wafer are compatible with your AFM instrument.

-

Cost and Availability: Silicon wafers can be more expensive than mica, so consider this in your budget planning.

Before making a switch, it might be helpful to consult with a material scientist or a specialist in AFM imaging to ensure that the silicon wafer you choose is appropriate for capturing ARP 2/3 images. Additionally, conducting preliminary tests to compare the performance of silicon wafers with mica as substrates in your specific experiments would be advisable.

Mica Used for Characterization XRD Analysis of Graphene Layers

A chemical engineer requested the following quote:

I want to order some blank silicon wafer (Mica) as substrate for characterization (XRD analysis of graphene layers), could you provide some product info and a quote?

Reference #214989 for specs and pricing.