I'm interested in purchasing 100ea of the 100mm x 0.5mm BK7 wafers(id 1610). Can you let me know what the thickness and flatness specs are for this material. Also do you folks offer lapping and polishing as a service? The flatness is not a big concern for this order, I do need to know what I could expect for thickness variation / tolerance, however.. Please provide a quotation for the Chinese BK7 lapped and polished to 540micorn thickness. The thickness spec is 540 micron +/- 10 microns.

BK7 Optical Glass Wafers for Research & Production

BK7 Glass for Research

And small device manufacturing company requested a quote form the following BK7 Wafers

UniversityWafer, Inc. Replied:

Yes, we do lapping and polishing. We have two Speedfam 16B-5 double sided polishers where we run Suba X polishing pads and Zirconium oxide polishing compound.

We also have two Speedfam 16B-5 double sided lapping machines that run 9 micron fixed abrasive 3M Trizact pads.

We also have an additional Speedfam 12B-6 polisher for overflow polishing work.

That being said, we do not have any metrology to measure flatness.

Would you like us to quote the above using this equipment without call outs on flatness?

Reference #269123 for pricing.

Get your BK7 Glass Wafer Quote FAST! Guaranteed!

BK7 Glass for Precision Lenses

BK7 Glass is consistently superior to the other industry standard glass. BK7 has proven its worth as an optical chromatic lens, and it is known for its ability to produce pristine color at all wavelengths with superior purity and superior optical performance. Research and development efforts continue to advance bk7 glass's capabilities as it is being used in thermal window panels to improve color fidelity and color accuracy, and its ability to produce high quality images in UV and visible spectrum.

Below are just some of the BK7 Optical Glass Windows that we have in stock.

Don't see what you need? Please send us your specs!

Highest Optical glass Manufacturer Quality

From our experience that they have different characteristics:

- Schott BK7: we think you know BK7 very well, as BK7 has best transmittance rate, but the price is high.For optic polished of all optic parts

- Ohara S-BSL7: it can be equilvalent to N-BK7 due to same transmittance rate with BK7, for polished part for both windows, plates also prism.

and S-BSL7 price advantage comparing with BK7 - Chinese K9 : this material can replace polished BK7 plate and windows with thinner thickness. It can not used for optical prisms. And this K9 glass has a very competitive price. this is very special.

We suggest you can make trial order for these three optical glass wafer to test it. The price gap will be much attractive.

Please contact us for an immediate quote.

Video: BKY Properties and Applications

BK7 & Equivalent Glass Applications

BK7 Astronomy

BK7 Optics

- Digital still cameras

- Video cameras

- Interchangeable camera lenses

- Binoculars

- Spotting scopes

- Digital projectors

BK7 Industrial

- Microscopy

- Laser fusion

- Geodesy

- Reprographics

- Professional image processing

BK7 Lithography

BK7 Lithography refers to photolithography performed on substrates made from BK7 glass, a high-quality borosilicate optical glass widely used in optical applications. BK7 glass (or N-BK7) is well-known for its exceptional optical clarity, high transmission, and low refractive index variations, making it an ideal substrate for precise photolithographic processes in optics and microelectronics.

Key Features of BK7 Glass:

- High Optical Quality: Minimal optical distortion, excellent clarity, and transmission.

- Low Bubble Content: Ensures uniformity essential for precise lithographic processes.

- Chemical Resistance: Stable when exposed to common chemicals used in lithography.

- Thermal Stability: Low thermal expansion coefficient, beneficial in precision alignment applications.

Why BK7 is Used in Lithography:

BK7 is commonly used as a substrate in photolithography because of its optical clarity and uniform surface. It supports fine pattern definition for applications like:

- Micro-optics

- Optical masks

- Photomasks for semiconductor device fabrication

- MEMS and microfluidic device manufacturing

Applications of BK7 Lithography:

- Photomask Fabrication: High-resolution masks for semiconductor chip production.

- Micro-optical Components: Lenses, prisms, mirrors, and other precision optical parts.

- Microelectronics: Manufacturing substrates requiring precise patterns for integrated circuits.

BK7 Lithography is popular due to BK7 glass’s ideal combination of optical performance, stability, and affordability, making it a preferred substrate for precision optics and microelectronics manufacturing.

BK7 Medical and Biotech

BK7 glass is extensively used in medical and biotech applications due to its superior optical clarity, chemical stability, biocompatibility, and high precision in optical performance. It is particularly valued in precision optics essential for diagnostic and analytical equipment.

Medical and Biotech Applications of BK7 Glass:

-

Microscopy and Imaging Systems

- BK7 lenses, prisms, and mirrors are used in high-performance microscopes and optical imaging systems for accurate visualization of biological samples.

- Essential for confocal microscopy, fluorescence imaging, and biomedical microscopy applications.

-

Spectroscopy and Diagnostic Equipment

- Used in spectrometer components for precise spectral analysis of blood, tissues, or biochemical assays.

- Provides accurate and distortion-free optical paths, critical for diagnostic accuracy.

-

Endoscopy and Minimally Invasive Procedures

- BK7 optical components facilitate high-resolution imaging in endoscopes, laparoscopes, and other minimally invasive surgical instruments.

- Enables surgeons to clearly visualize internal anatomy during procedures.

-

Laser-Based Medical Equipment

- Utilized as optical windows, lenses, and mirrors in medical lasers used for therapeutic procedures, ophthalmology, dermatology, and cosmetic treatments.

- Supports precise control and delivery of laser energy to targeted tissues.

-

Biophotonics and Microfluidics

- BK7 substrates are employed in microfluidic chips, optical biosensors, and lab-on-chip devices, supporting precise detection and analysis of biological molecules.

- Critical in applications involving optical sensing, fluorescence assays, and real-time biochemical analysis.

-

Biometric and Diagnostic Sensors

- Used in optical components for biometric sensors and diagnostic devices such as retinal scanners, biometric imaging, and optical coherence tomography (OCT).

Advantages of BK7 Glass in Medical and Biotech:

- High Optical Transmission: Ensures maximum efficiency and clarity for imaging and detection.

- Chemical and Environmental Stability: Resistant to biochemical environments, facilitating sterile and accurate diagnostics.

- Precision Optical Performance: Minimizes distortion, maximizing accuracy in medical imaging and diagnostic systems.

- Biocompatibility: Non-reactive, safe, and suitable for direct interaction with biological samples and tissues.

Overall, BK7 glass’s superior optical and physical characteristics make it a cornerstone material in the development of sophisticated medical and biotech optical systems.

- Microscopy

- Medical engineering

BK7 Security and Other Uses

BK7 glass plays a key role in security applications due to its exceptional optical properties, clarity, and durability. In security fields, it's primarily utilized in precision optical systems requiring high transparency, reliability, and stable performance.

How BK7 Glass Is Used in Security:

- Surveillance and Imaging Systems

- Used in high-quality lenses and optical components for security cameras and surveillance systems.

- Ensures clear, distortion-free imaging crucial for surveillance cameras, facial recognition systems, and infrared imaging.

Specific Security Applications:

-

Security Camera Systems:

- BK7 lenses provide excellent optical clarity and precise imaging for high-resolution CCTV cameras, facial recognition, and object identification.

-

Optical Sensors:

- Employed in intrusion detection systems, BK7 glass facilitates reliable transmission of light signals for laser-based sensors, infrared barriers, and perimeter security monitoring systems.

-

Night Vision Equipment:

- BK7 optics enhance clarity and resolution in night-vision systems, thermal imaging, and infrared optics used by military, law enforcement, and surveillance equipment.

-

Fingerprint and Biometric Systems:

- Optical components made of BK7 glass support accurate biometric readings, enhancing reliability in fingerprint scanning and iris-recognition systems.

-

Surveillance Drones and UAVs:

- High-precision optics made from BK7 are crucial in aerial surveillance equipment, ensuring accurate and stable imaging over long distances.

Advantages of BK7 in Security Applications:

- Superior Optical Performance: Clear images with minimal distortion and precise detail.

- Durability: Resistance to harsh environments, chemicals, and temperature fluctuations.

- Consistent Performance: Stable optical properties over time, critical in sensitive security monitoring systems.

- Resistance to Environmental Factors: BK7 glass withstands environmental factors such as humidity, temperature variations, and chemical exposure.

By providing consistent optical quality, precision, and reliability, BK7 glass enhances the effectiveness and dependability of numerous modern security technologies.

What are BK7 Glass Applications?

BK7 glass is a high-quality optical glass that is commonly used in a variety of applications, including lenses, windows, and prisms. It is known for its good optical properties, including high transmission in the visible and near-infrared regions of the spectrum, low dispersion, and low absorption. BK7 glass also has a high refractive index, which means that it can bend light to a high degree. These properties make it an ideal material for use in applications where clear and undistorted images are required.

BK7 (Belgravia K7) is a polycarbonate material containing a binder and a low dispersion impurity. BK is the trademark for a new generation of monochromatic refractive index lenses. A bk7 lens is made up of a single crystal of carbon and can be obtained in different alloys depending on the thickness of the binder. The major difference in bk7 and other carbon based glass is found in the dispersion of light at the optical interface. Because light is able to travel through a medium at different speeds, the refractive indices of bk7 and other carbon based materials are always different from one another. When the optical interface is smooth, multiple wavelengths of light will be deposited on the surface as a refracted image.

Because bk7 is so unique, its dispersion properties have been studied extensively. Optical microscopy has revealed that bk7 produces sharp, well defined images when viewed through micro-disposable mirrors. Because bk7 has low dispersion, it has superior optical quality than any competing product on the market. Scientists are currently exploring many ways to use this material to advance optical technology.

Currently, the material is most commonly employed in microdissection tools such as optical microscopes. Microdissection allows scientists to obtain much more information about biological and structural materials than is possible with standard techniques. To this end, a wide variety of biological and structural studies are carried out using bk7 lenses and microdissections.

Currently, the material is most commonly employed in microdissection tools such as optical microscopes. Microdissection allows scientists to obtain much more information about biological and structural materials than is possible with standard techniques. To this end, a wide variety of biological and structural studies are carried out using bk7 lenses and microdissections.

In order to test the efficacy of bk-7 glass in terms of improving microdissection results, scientists look for two different ways to alter the glass. One method involves using ordinary glassware with a small amount of bk7 between the two layers. The purpose of this method is to remove small amounts of residual bk from the bottom layer so that the top layer of bk-7 can be examined.

The second method requires extremely low amounts of bk7. A thin film of bk7 is used and it is applied directly to the microscope slide. This method produces very clear images with excellent resolution. Because this thin film doesn't have any residual bk, it is highly flexible. Because of its high optical clarity of field, the surface roughness of the glass improves. The number of times that an observer has to move the slide in order to see a difference in field and image depth is less than in the case of regular microscope slides.

One important advantage of the bk7 optical glass wafer is that it can be used to create lenses for microscopic applications. For example, observation has revealed that bk7 can be successfully used to make lenses for scanning electron microscopy. Lenses using bk7 have also been used to create high resolution optomechanical imaging devices. In addition, bk7 lenses can be used to fabricate high optical thickness materials like plastic foils. Lenses having bk7 coating have been successfully employed for coating glass and metal surfaces in many optical applications.

As mentioned above, bk7 and other microdissection techniques can be used to create microdissections with excellent resolution and clarity. This enables researchers to examine very small objects in great detail and saves time and money. Researchers will still need to use traditional microdissection techniques, such as manual tissue removal and tissue dissection. However, the high optical clarity of bk-7 and other microdissection techniques makes them a cost-effective alternative to manually dissecting large pieces of tissue.

BK7 Glass for Precision Lenses

Below are just some of the BK7 Optical Glass Windows that we have in stock.

Don't see what you need? Please send us your specs!

Buy as few as One BK7 Wafer Online!

| Item | Dia (mm) | Thick (μm) | Pol | Qty in Stock |

| 1609 | 76.2 | 500 | DSP | 100 |

| 1610 | 100 | 500 | DSP | 100 |

| 1611 | 150 | 500 | DSP | 100 |

Same Day Shipping for in-stock items!

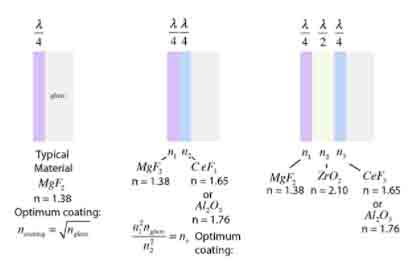

Need Anti-Reflective Coating on your Glass Wafers?

We provide anti-reflective coating on BK7 and other glass wafers. Please send us your specs for an immediate quote.

An anti-reflective coating is a sort of internal anti-reflective coating applied to an object to lower reflection. In simple imaging systems, it improves the resolution as less light is transmitted because of reflection. The term anti-reflective is usually used in conjunction with glasses that have internal anti-reflective coating to further enhance the anti-reflective properties of the glass. Since the glass may also have other internal qualities like thermal, hardness or durability, the coating may be on top of or below the glass.

Why Apply Anti-Reflective Coating?

For photographic applications, it may be possible to apply an anti-reflective coating to improve the visibility and prevent the glare from sunlight off of technical equipment lenses. It is usually applied on top of the glass to protect it from the reflection of the sun's rays off of surfaces that pass through the lens. If the technology is sufficiently advanced, a thin layer of anti-reflective coating may be able to be applied on the bottom of the glass, which would negate the need for a top coating. However, without some sort of internal coating, even top quality glass which has been toughened to be impact resistant may still accumulate significant amounts of glare if it is placed in front of an imperfective polarizer filter which reduces the effectiveness of the anti-reflective coating.

There are two broad categories under which anti-reflective treatments are classified. The first is the pure anti-reflective treatment where the glass is coated with an internal anti-reflective coating which prevents some reflected light from penetrating the coating and entering into the eye. This can sometimes compromise the functionality of prescription lenses by making the eye-space smaller due to reduced transmission. The second type of anti-reflective treatment involves the application of a high-quality coated coating which either eliminates or significantly reduces the amount of reflected light. Both of these types of treatment can greatly reduce the amount of glare and improve vision. In recent years, new technologies have allowed manufacturers to produce glasses with anti-reflective lens coatings which are nearly identical to those found in designer eyeglasses. In certain applications, these glasses are indistinguishable from regular glasses. These designer anti-reflective lenses are intended for individuals who want to have high quality vision without the high costs that go along with purchasing designer glasses.Lenses with anti-reflective coating are designed to reduce eye fatigue when driving. Current research indicates that the anti-reflective coating helps to reduce eye fatigue when driving by nearly two-thirds compared to without coating. The anti-reflective lens coatings also reduce eye strain because they eliminate the scattering of light that occurs during continuous eye movement. Some research even suggests that the anti-reflective coating helps to prevent certain eye diseases such as cataracts and glaucoma. Other types of research suggests that the anti-reflective lens coatings may help reduce the incidence of glare-related eye cancer and cataracts. Anti-reflections are usually detected by an experienced eye care professional as an eye condition known as "refractive errors." Eye care professionals determine that the individual experiences refractive errors if he or she has an overly large pupils which cause reflections in certain lights. Some reflections on the human face are more noticeable at night because of the low level of illumination in darker settings. Many drivers suffer from excessive eye strain because of their inadequate visibility lighting. By wearing corrective lenses, these individuals can significantly reduce or eliminate the amount of eye strain.

Many manufacturers have developed high quality anti-reflective coatings for use on their own brands of eyewear. Since most full face contact lenses are coated, it is possible to order anti-reflective lenses online. There are several websites that sell these lenses with various coating options. One can select the coating that is most effective for their own situation. Some websites even offer discounts for large orders.

Anti-Reflective coatings provide many benefits to those who wear glasses or contact lenses. Some of these benefits include reduction of glare, prevention of cataracts and reduced eye strain. It is not always possible to eliminate all possible reflections from a person's face. The anti-reflective coating will simply reduce the amount of visible reflections. Some individuals who are sensitive to certain colored contacts might consider purchasing a different type of eyeglass. Many people who cannot tolerate anti-glare will find that these anti-reflective lenses provide enough color control for them.