What are D263 Glass Wafers used for?

Researchers have used D263 Glass wafers cleaving model was investigated based on the principle of thermal stress fracture. The thermal stress in the material was calculated. Experimental studies were performed to investigate the processing parameters, and D263 glass sheet with thickness of 300 µm was cut, resulting in micro crack-free edges with a surface roughness of 0.5 nm. The proposed process was also applied to cut X-ray telescope lenses substrates with no micro cracks. Compared with diamond scribing and laser cutting, the proposed method is lower capital costs and yields a nondestructive cut surface for glass. The technique can be applied in manufacturing glass products (i.e. lenses, solar cells, glass screen).

Microchip Fabrication Using D263 Borosilicate Glass Wafers

Researchers have used D263 glass for consistent microchip fabrication with smoothly etched channels for more accurate readings.

University scientists have researched the causes of rough etching including the effect on different glass including D263 glass substrate annealing on improving rough etching and etching of a different form of borosilicate glass. The scientists have discovered that D263 glass has advantages over Borofloat glass wafers.

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

What Glass Substrate Should I Use for Imaging of Sub-Micron

Particles?

Scientists have used the following low cost D263 spec for their research and development for imaging sub-micron particles.

D263 Item #1615 50.8mm 550um DSP

Substrates for imaging of sub-micron particles are used extensively in the field of applied chemistry and biochemistry. Substrates are mainly used as an absorbent in gel electrophoresis assays, where a sample is coated with a gel that has been electrically charged. The gel is then placed on a microplate where a fluorescent dye will be detected. Substrates can also be used to study chemical reactivity or the development of radicals.

Substrates are used for many different applications and they can be prepared at home on a laboratory bench. These can be prepared from commonly available materials such as silica gel, dried seaweed, sand, rock wool, ceramic tile, wood powder, calcium carbonate and glass powder. Some of the most common substrates for this application include sodium bicarbonate, silica, magnesium oxide and boron carbide. These substrates are used widely in research chemistry and they have produced promising results.

Substrates for development of antibodies have had quite a bit of recent success. Substrates that are developed from cells in culture have been shown to have properties that are nearly identical to the proteins of living things such as chicken and animal cells. Protein-based antibodies are being used to treat disorders of various types and the medical world is still looking at these methods and how they may be used in the future. Substrates for development of antibodies can also be made using the protein based synthetic enzyme. This method produces antibodies that are half mirror images of their own protein.

Substrates for development of enzymes are also used. Enzymes are very important in the chemical reactions that go on within the cell. When these enzymes interact with specific molecules they produce a reaction that produces the desired outcome. Scientists are looking at several methods of developing enzymes and they are hoping that this will lead to the development of medicines. If successful, this could revolutionize the chemical industry.

Substrates for development of enzymes can be prepared from plant materials. A variety of different enzymes are needed for a number of different processes. Two of the most popular enzymes used for this purpose are literate and cysteine. These substances can be found in many foods and some plants are already grown that contain them. Other methods are being considered.

Substrates for imaging of sub-micron particles have also been developed. In this method an electron microscope is used to look at the submicron level. Antibodies are then created using zinc to stop them from doing what they are intended to do. Substrates for imaging of sub-micron particles are produced in this method as well.

Substrates for development of antibodies are produced using lysine and T-discs. These lysine-T discs are produced by sheep and are under research. The method is still in the early stages and there are other methods being researched. Substrates for imaging of sub-micron particles and methods used to develop these proteins are similar in many ways.

Many people want to know what substrates are and how they are used. Substrates for imaging of particles in the ultra-violet region have been developed. Ultrasonic imaging uses ultrasonic sound waves to create a hard image on the surface of the substrates. Other substrates are based on techniques that use high frequency sound waves. Substrates for imaging of sub-micron particles can be used for development of a number of different medications.

Some research focuses on developing a variety of antibiotics. There are many drugs available that are not very effective if they are used for long periods of time. A compound that is made from sulfur has been used in the development of some antibiotics. This compound is used to break down foreign bacteria and it has been successful in many studies. Substrates for protein crystallization may be used to help with the development of antibodies as well.

All of these different substrates for protein development have their own specific uses. These substrates are often used in the development of proteins and other molecules that are then used in drug research and development. One of the better-understood ways of using substrates is in the area of antibody studies. Several classes of antibodies have been developed over the years and one way to study these antibodies is with the use of various protein development substrates.

Substrates for protein crystallization can be used as a protein source, as a partial protein replacement for an existing protein source or even as part of a larger protein development process. In many cases, substrates are used together with other methods so that researchers can examine how specific processes work together. For example, some protein crystallization methods use fluorescent proteins that are fluorescently tagged with amino acids. Other methods use fluorescent labeled fluorescent proteins coupled with other types of labeling agents. These substrates can be used to study the crystal formation of different types of proteins and antibodies.

Our clients use our Schott D263 glass for the following applications:

- Touch Panel Controls

- Liquid Crystal Displays (LCD)

- Electroluminescent Displays

- Solar Cell Protective Glass

- Glass Substrate for Coatings

- Micro Scales for Measuring Devices

Buy D263 Glass online and save!

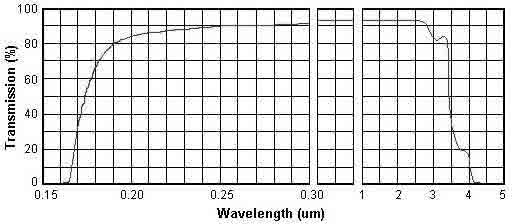

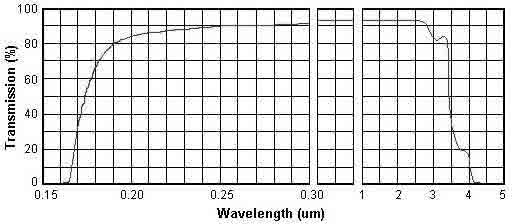

D263 Transmission Curve

A scientist asked the following:

"I'd like to get a quote for 1000 D263 wafers, at 500 um thickness. I'd like to know if we can get them with a flat, as it helps in the alignment process. I'd also like to know if you sell quartz wafers that would ideally be transparent from 250 nm to 3000 nm (perhaps you have a transmission profile of a couple?)"

I'm okay with 100 mm diameter but if you have 150 mm it would be good too as they are to but cut for device fabrication. About the d263 wafers, is there a chance for the flat?

What would be the cost difference between big and small quartz wafer per unit?

UniversityWafer, Inc. Provided:

How high a Temperature can D263 Glass Handle?

A scientist recently asked us about D263 heat tolerances:

Our research group is looking too buying some D263 Glass from your company, the only specification that we need to know that we can’t find on the website is how high heat can it handle? We need to apply a thin film on top of it to heat it in the furnace, we’re looking at temperatures of 900 C or a bit higher for a few hours. Can this glass handle that without cracking?

The other specifications don’t matter as much due to the nature of the experiment, the only big specification we need is that it can handle high temperatures for a few hours. If it can, then we were going to purchase the 50mm glass wafer you have in stock so as to avoid any lead time, id 1615. 10 pieces. The polish and thickness of the listed item is sufficient for us.

UniversityWafer, Inc. Replied:

D263 is not suitable for use in up to 900 deg C. 500 plus degrees Celsius. However you cannot shock the material or it will break. It has to be gradually heated. But Fused Silica will work.

Thank you for the offer but because D263 glass can’t handle the high temperatures we need, we’re going with fused silica as per your suggestion. I’ve forwarded the item to my research head and he’ll make a purchase on it soon from your website.

What is the Maximum Temperature that D263 Wafers Can Handle?

150mm D263 Glass Wafer: \ Strain Point 529°C \ Softening point 736°C

Thickness: 675um. 0.550mm is the closest D263 is available