Semiconductor and Related Device Manufacturing Service

Smaller Semiconductor Geometries

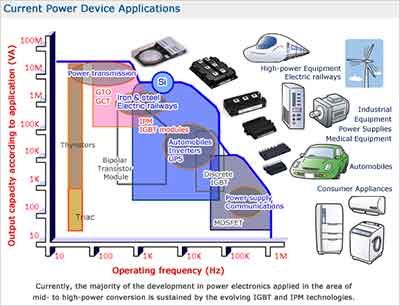

Advances in transistor technology are focused on the tiny semiconductor geometries required for radio frequency transistor applications. One of the most important aspects of transistor development in recent years has been the ability to reduce each transistor to size. Semiconductor companies have become accustomed to using smaller and smaller geometries (i.e., to incorporate a larger number of approaches into an integrated circuit) to reduce costs. [Sources: 0, 11, 12]

Get Your Quote FAST! Buy Online and Start Researching Today!

Semiconductor and Related Device Manufacturing

If you need semiconductor NAICS code list, Electronics Manufacturing SiC Codes, please fill out the form.

We look up the SIC codes for you!

Semiconductor And Related Device Manufacturing

There are three basic types of integrated circuits currently being manufactured by American semiconductor manufacturers: memory components (used to store data for computer programs), logic devices (which perform operations such as mathematical calculations), and components that connect the two. In fact, ASICS application - specific integrated circuit - has become the most commonly manufactured semiconductor without microcomponents. [Sources: 2]

Another important product in the industry is the semiconductor diode stack, which includes integrated microcircuits for light scanning and emission of semiconductors and solid state devices. Integrated circuits are manufactured in large quantities and are considered process drivers. An example of a product manufactured by this company is a powerful, cost-effective and powerful microcontroller (MPC). [Sources: 2, 10]

The doped silicon wafers and the semiconductor diodes in the silicon diode stack are the starting material for the production of semiconductors and interfaces. The impurities supplied to the diodes, such as silicon dioxide (SODI) and silicon nitride (SiN), act as impurities and cause the formation of the compound. [Sources: 0, 7]

The semiconductor industry is truly international, with all the major manufacturers in the US, China, Japan, South Korea, Taiwan and the UK. Intel is the world's largest semiconductor manufacturer and a major supplier of silicon diodes. Toshiba Corp. is one of the best-known companies in the industry, along with Samsung Electronics Co. Ltd. and Intel Corporation. Although tantalum is considered a technological - critical - element, it is also found in a number of other materials such as copper, nickel, copper oxide, cobalt, lead, zinc, silver, gold, platinum, manganese, iron, magnesium, tin, cadmium and copper. [Sources: 2, 3, 6]

Patents Cooperative Patent Classification (CPC) is a class of patents held by the United States Patent and Trademark Office (USPTO). This class primarily comprises semiconductor devices, but also a number of other materials such as copper, nickel, copper oxide, cobalt, lead, zinc, silver, gold, platinum, manganese, iron, magnesium, tin, cadmium and copper. Leading carriers of semiconductors and related device patents include Intel, Samsung Electronics Co. Ltd., Toshiba Corp. and LG Chem Ltd. [Sources: 5]

Semiconductor manufacturing is a process for manufacturing metal oxide semiconductor devices (MOS) used in everyday electrical and electronic devices such as integrated circuits (IC) and chips present in every everyday electrical or electronic device. Also called a chip, an integrated circuit is a microminiaturized electronic component (or microelectronic device) placed in a tiny rectangle of silicon. Semiconductors and device manufacturing are the processes for producing the metal oxides (semiconductors) of metals and materials (copper, nickel, copper oxide, cobalt, lead, zinc, silver, gold, platinum, manganese, iron, magnesium, tin, cadmium and copper) that make up the components of an integrated circuit, or IC (chips), which are present in everyday electrical and electronic equipment. The production of sedimentary components is one of several processes used to manufacture electronic components in integrated circuits (ITC) or integrated circuits (i.e. chips), which are present in everyday electronics and electronic components in addition to electronic components. (e.g. mobile phones, tablets, computers). [Sources: 2, 4, 9]

TI's products and services include semiconductors, high-performance semiconductor and electronic components, energy management systems and other products. Semiconductor companies primarily develop and manufacture integrated circuits (ICs) and microelectronic components (chips) for the electronics of everyday life. [Sources: 2]

For example, our customers have helped develop a large patent portfolio for vacuum equipment in semiconductor manufacturing, many of which we have developed ourselves. We have also assisted our customers in developing large patents and portfolios related to the vacuum used to handle the liquids and gases used in the manufacture of semiconductors. [Sources: 1]

The Semiconductor Devices Standard Group (Group 18) can provide information related to production standards for the manufacture of the desired semiconductors and devices. Bandout information can include a description of the device design and information from the sources involved. Source Group 20 can provide information about the process of selecting a foundry to produce the materials and materials needed to manufacture a desired silicon semicode device. Product Development Group 28 could provide information on product design, manufacturing process and production requirements for a particular product or product line. [Sources: 8]

The GUI [44] for semiconductor device design provides the ability to enter information on the design of semiconductor devices, which can include a description of the device design, bandout information, and other information about the design and manufacturing process. The design information of the received semiconductors is then converted into a format relevant to the production site selected for the manufacture of the semiconductor device. Semiconductor and related device manufacturing information entered with the chipset design GUI is stored in a database of information. Since we are now examining information about the methods of transistors and the production of semicidal components, we have referred to FIGS. [Sources: 0, 8]

Sources:

[0]: https://patents.google.com/patent/US3025589A/en

[1]: https://www.hbsr.com/technologies/semiconductors

[2]: https://www.referenceforbusiness.com/industries/Electronic-Equipment-Components/Semiconductors-Related-Devices.html

[3]: https://irds.ieee.org/topics/new-challenges-facing-semiconductors

[4]: https://en.wikipedia.org/wiki/Semiconductor_device_fabrication

[5]: https://www.ceg.org/articles/greater-share-us-semiconductor-device-patents-ties-capital-region-inventors-2018/

[6]: https://www.thebusinessresearchcompany.com/report/semiconductor-and-related-devices-global-market-report

[7]: https://www.allaboutcircuits.com/textbook/semiconductors/chpt-2/semiconductor-manufacturing-techniques/

[8]: https://www.google.com/patents/US7197723

[9]: https://www.wikidoc.org/index.php/Semiconductor_device_fabrication

[10]: https://siccode.com/naics-code/334413/semiconductor-device-manufacturing

[11]: http://maltiel-consulting.com/Semiconductor_Manufacturing_101_maltiel-consulting.html

[12]: https://www.valueline.com/Stocks/Industry_Report.aspx?id=7258

article to learn about its Function, Structure, Doping, and Manufacturing. If you have any questions, you are encouraged to leave them in the comments below. Thanks for reading! And please share it with your friends and family.

article to learn about its Function, Structure, Doping, and Manufacturing. If you have any questions, you are encouraged to leave them in the comments below. Thanks for reading! And please share it with your friends and family. chips, or a cluster of several chips and / or a combination of both. Digital integrated circuit : Digital integrated circuits can contain a variety of components, from chips to chipset components and even a range of discrete chips.

chips, or a cluster of several chips and / or a combination of both. Digital integrated circuit : Digital integrated circuits can contain a variety of components, from chips to chipset components and even a range of discrete chips. Compared to ICs, discretes are cumbersome as each discrete must be designed for a specific circuit. But you can build complete circuits with a multitude of discretes. ICs appear simplifies the design process of the integrated circuit and its integration with other components. The design process is the most expensive part of fabricating semiconductors.

Compared to ICs, discretes are cumbersome as each discrete must be designed for a specific circuit. But you can build complete circuits with a multitude of discretes. ICs appear simplifies the design process of the integrated circuit and its integration with other components. The design process is the most expensive part of fabricating semiconductors.