Please quote the following items with delivery :

3" and 4" Quartz wafer

Orientation: x-cut 2 degree and X-cut 4 degree

Thickness: 100-200um

Surface: Double side polished

Q'ty: minimal of quantity

X-Cut Quartz for Research & Production

Thin X-Cut Quartz Substrates

A university researcher requested a quote for the following:

Reference #97240 for specs and quantity.

Get Your Quote FAST! Or, Buy Online and Start Researching today!

Seedless X-Cut Quartz Wafers

An optics engineer requested a quote for the following:

Please let me know if you can offer the following quartz wafer:

SiO2 wafer (10-12), seedless, Right handed if possible

Dia 2" x 1mm thick

one side epi-polished

back side optically polished

S/D: 60/40, FLAT X-cut

QTY: 10

Orientation deviation: <0.5°

tolerances in size and thickness:

+/- 0.05mm

surface quality of polished

surface:

-scratch-less at

magnification 50x

-roughness: Ra < 0.5 nm

| Dia | Ori | Thick | Pol | Seed | S/D | Ra |

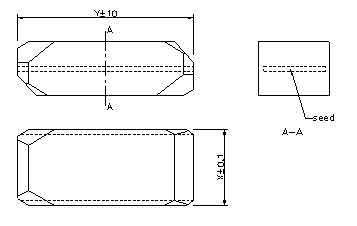

| 2"+/-0.05mm | X-cut 0°00'+/-0.2° | 1+/-0.05mm | DSP(optical polish) | with seed | 60/40 | <10A |

Reference #121119 for specs and pricing.

What are X-Cut Quartz Crystal often used for?

X-cut quartz crystals are commonly used in electronic devices for their excellent piezoelectric properties. When subjected to mechanical stress, they generate an electric charge, and vice versa. This makes them ideal for use in:

-

Frequency Control: X-cut quartz crystals are often used in oscillators for maintaining a stable frequency. They are key components in watches, clocks, radios, computers, and mobile phones to ensure accurate timekeeping and signal processing.

-

Filters and Resonators: Due to their ability to resonate at specific frequencies, X-cut quartz crystals are used in electronic circuits as filters to select or reject certain frequencies. This is crucial in communication devices like radios and televisions.

-

Sensors: The piezoelectric effect of X-cut quartz crystals makes them useful in various sensors, such as pressure sensors, accelerometers, and microbalances. These sensors are used in a wide range of applications, from automotive systems to medical devices.

-

Stability in Extreme Conditions: Quartz crystals, including the X-cut variety, are known for their stability under temperature changes and other environmental factors, which makes them suitable for use in military and aerospace applications where reliability is critical.

In summary, X-cut quartz crystals are valued for their frequency stability, precision, and reliability in a wide range of electronic applications.

Why Use X-Cut Quartz Wafers?

X-Cut quartz crystal is an excellent material for a wide range of applications, from electronics to medicine.

X-Cut Quartz Applications?

X-Cut quartz crystal is an excellent material for a wide range of  applications, from electronics to medicine. Its trigonal symmetry, or "Y-shape," is characteristic of the crystal. The Y-shape wells are 750mm long and 250mm wide, and are oriented perpendicular to the straight side edge of the wafer. A common tensile strength of the material is 250 GPa.

applications, from electronics to medicine. Its trigonal symmetry, or "Y-shape," is characteristic of the crystal. The Y-shape wells are 750mm long and 250mm wide, and are oriented perpendicular to the straight side edge of the wafer. A common tensile strength of the material is 250 GPa.

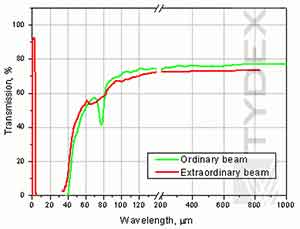

In an X-Cut quartz acousto-optical modulator, the two quartz chips have a similar cross section. The Y-axis is perpendicular to the flat surface. Ordinary rays and extraordinary rays both follow the same path through the crystal. This birefringent property allows the glass to retain its polarization, even when the crystal is cut in a unique pattern.

One preferred embodiment of the present invention uses a rectangular X-Cut quartz crystal resonator with aspect ratios of 0.3 to 0.5. The rectangular X-Cut quartz resonators have bottom thicknesses of 10 to 50 mm. The resulting semiempirical frequency equation can be used to estimate constants. The contours show a zero first order temperature coefficient condition.

GT cut is the best choice for high-frequency operation. Its geometry provides repeatability. It uses a 49deg angle from the z axis to guide the growth of nanowires. Its frequency constant is 2.536 MHz/mm. However, it is slightly less stable than AT cut. And it is a less expensive material. It can also be very useful for a variety of applications.

In contrast, a single-crystal quartz plate is not always an X-cut crystal. This is an alternative form of single-crystal quartz. In this case, the two parallel flat surfaces are perpendicular to the X-axis. A similar arrangement may be used for a single crystal quartz plate. For example, a high-frequency signal is supplied to the transducer through an RF drive voltage input. The acoustic wave propagates through the bulk of X-Cut quartz block 3.

The X-Cut quartz process requires several stages. The overall chip size is 45x22mm. The size of the wells is 1.6mm. Afterwards, it is lapped on a precision lapping machine. The resulting X-Cut quartz chips are perfect for a variety of applications. In fact, they are so thin that they can be used as a touch screen. So, it is possible to use them to build smart phones, tablets, and other types of electronic devices.

The X-Cut quartz crystal is generally oriented perpendicular. It produces relatively high figures of merit when oriented perpendicularly. Similarly, the Y-Cut quartz is cut at an angle of 35deg 25' to the Z-axis. At an angle of 150deg, it is a common method in the production of radio systems and microprocessor clocks.

X-Cut quartz crystal is a popular material for high-end devices. Its acoustic properties make it an excellent material for radio transmitters. As with other materials, it is ideal for RF and microwave signals. The X-Cut quartz crystal has a high figure of merit and is preferred for optical and electrical components. Despite its low photoelastic constant, this material is widely used in medical equipment and lasers.

The X-Cut quartz is a type of quartz with a single diffraction. It is best used for applications where you need a single-crystal object is required. The X-Cut quartz is an excellent choice in this application because it is transparent to x-rays and is suitable for a variety of laser beams. In addition, it has the highest surface energy of any material.

Another advantage of X-Cut quartz is its flexibility and ease of manufacture. The X-Cut quartz is more durable than fused silica, and requires only a third of the drive power. Its high diffraction performance makes it a good choice for a wide range of applications. Its high diffraction efficiency is the same as that of a quartz diffraction device.

The X-Cut quartz is a popular choice for acousto-optical modulator. Compared to fused silica, this material has higher L-values than fused silica. Its X-Cut quartz acousto-optical modulators are able to reduce the sidewall crystal edges. Using a Y-Cut quartz acoustoscope, the researchers can view a wide range of applications and analyze the reflected echo.

What is X-Cut Quartz Crystal?

An X-Cut quartz crystal is a single-diffraction-mode crystal. It is best suited for applications  requiring single-crystal objects. Moreover, it is transparent to x-rays and suitable for laser beams. Moreover, it also has the highest surface energy among all the materials. However, it has several disadvantages. Here are some of these disadvantages: a.

requiring single-crystal objects. Moreover, it is transparent to x-rays and suitable for laser beams. Moreover, it also has the highest surface energy among all the materials. However, it has several disadvantages. Here are some of these disadvantages: a.

X-Cut quartz crystals are rectangular-shaped and have a trigonal symmetry. They are cut at an angle of 35 degrees to the Z axis. The X-Cut quartz crystals are used in high-end devices due to their excellent acoustics. It also exhibits a high figure of merit and is therefore suitable for use as optical and electrical components.

X-Cut quartz crystals are generally perpendicular to the Z axis. Y-Cut quartz crystals are angled 35 degrees to the Z-axis. As technology advances, these axes become more parallel. As such, top frequencies operate in an overtone mode. Thus, a X-Cut quartz crystal has a significant advantage over other cuts in this category.

X-Cut quartz crystals are oriented perpendicular to the Z axis. On the other hand, Y-Cut quartz crystals are angled at an angle of fifty-one degrees to the Z axis. These cutting angles have a significant influence on the frequency range of X-Cut quartz crystals. They also have higher acoustic properties. Hence, they are ideal for RF and microwave signals.

There are three types of X-Cut quartz crystal. The Y-Cut is more common and has higher figure of merit. This type of cut is perpendicular to the Z axis. It has a high polarization index and is ideal for acoustic applications. The Y-Cut is better suited for electrical and optical components. This type is also often used in lasers.

X-Cut quartz crystals are the most popular types. They are oriented perpendicular to the Z axis and are ideal for RF and microwave signals. They also have good figure of merit and are used in various kinds of electronics. Despite their high price, the AT-Cut is the most popular. It is highly effective and has a high price tag. It is an expensive material, however.

The X-Cut quartz crystal is the best quality and most popular cut in the world. It is the perfect material for lasers, as it is perfect for polarization. It is also ideal for capturing light from both the Y-axis and the z-axis. Besides being highly durable, it also offers a high figure of merit. This makes it the most desirable for most applications.

X-Cut quartz crystals are the best choice for lasers. These are trigonal, but they have high figures of merit. They are ideal for RF and microwave signals. As a result, they are ideal for detecting IR and UV signals. A Y-Cut quartz crystal has higher figure of merit than the AT-Cut quartz crystal. It is better for acoustic purposes.

There are many types of quartz crystals. The X-Cut is more popular. It has a trigonal symmetry and is commonly used for optical components. The Y-Cut is better for polarization. Its high figure of merit can be detected by an astronomer. This is why X-Cut is so valuable. The Y-Cut is more expensive than Y-Cut.

X-Cut quartz is a flexible material and more durable than fused silica. It requires a third of the power to produce. This cut is also more affordable than the AT. It is a popular choice for acousto-optical modulators. While the X-Cut quartz crystal is more expensive than the AT-Cut quartz crystal. The Y-Cut is an optimum choice for most high-frequency operation.

The angle of an x-cut quartz crystal blank is crucial for its operation and performance. The x-cut is the simplest cut, while the y-cut is the most complex. Consequently, cutting quartz crystals properly is very important. The right angles are important. A square-cut quartz crystal is a good choice if you are looking for a precise, flat-cut quartz.