What Is Dry Etching?

Dry etching is a semiconductor fabrication process that uses low-density plasma to achieve high energy  reactions at a low cost. This process uses small quantities of chemicals and electricity to produce high-resolution structures. Manufacturers can gain advanced resolutions by using dry etching instead of expensive photolithography tools. Dry etching has a variety of benefits for manufacturers, including high aspect ratio structures and less expensive equipment.

reactions at a low cost. This process uses small quantities of chemicals and electricity to produce high-resolution structures. Manufacturers can gain advanced resolutions by using dry etching instead of expensive photolithography tools. Dry etching has a variety of benefits for manufacturers, including high aspect ratio structures and less expensive equipment.

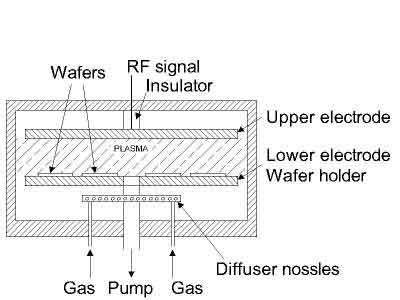

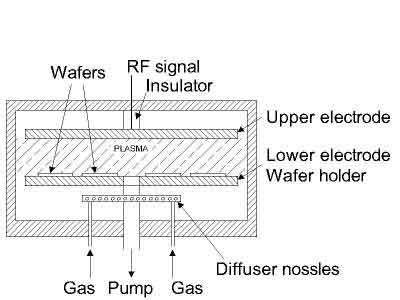

Reactive Ion Etching

Reactive-ion etching is a type of dry etchanting used in microfabrication. In this process, a chemically reactive plasma is generated in the presence of an electromagnetic field. The reaction enables the material deposited on a wafer to be removed. A chemically reactive plasma has a high rate of removal. To learn more about this technology, read on.

This method is a physical dry etchant. During the etching process, argon ions with energies of one to three keV are radiated on a surface. The wafer is held perpendicular to the ion beam. This makes the etching process absolute anisotropic, but the selectivity is low, as it is impossible to distinguish between individual layers. The gas and struck out material are exhausted by a vacuum pump. However, this results in particles depositing on the walls of the chamber.

The main benefit of this method is its flexibility and adaptability. This type of etching process enables users to control the etching rate, reproducibility, uniformity, and anisotropicity. Reactive ion etching is one of the most common etching processes in the semiconductor industry. Besides that, it's also the fastest and most versatile method of dry etching.

Reactive ion etching is a method of removing organic material by means of ion transfer. Unlike conventional etchants, ion etching is a dry process, so the RIE process is often preferred for many manufacturing processes. However, unlike other types of etching, it is highly adaptable. Increasing the power of the ICP-RIE reactor helps control the etching rate.

Reactive ion etched materials are extremely hard to clean. Because of the high-temperature nature of this process, the plasma is a risk to sensitive electronics. Therefore, it is important to protect sensitive electronic components from high temperatures and ion beams. In addition, reactive ion etching is recommended for sensitive parts, such as photosensitive devices. The process is also effective for the etching of organic materials.

The main difference between RIE and wet chemical etching is in the use of ions. In the latter, the ions have highly directional properties, which can reduce the need for a wet chemical etching. The ions can be directed horizontally or vertically to achieve the best etching result. RIE can also produce a very wide variety of surface features on a surface.

The rate of SiC etchant is proportional to the percentage of oxygen in the mixture. A maximum etching rate is achieved at about 60 percent of O2 content, where it then gradually decreases. Sugiura et al. found that SiC etching rates were only slightly higher at 40 percent O2 content. The addition of oxygen to the mixture increased the amount of reactive F atoms.

The method of dry etching was developed for power devices made of silicon carbide. It requires a high surface quality and higher etching rate. However, if the substrate is relatively hard, a dry etching process is more effective. A higher DC bias voltage is required to increase the rate of etching. For semiconductor devices, the gas flow rate should be controlled to prevent excessive etching.

Oxygen content of the plasma is an important factor that determines the rate of etching. An increased oxygen content in the plasma may improve the efficiency of the oxidation process. However, increased oxygen content may also reduce the roughness of the SiC etched surface. Further, the micromask effect may lead to the removal of a metal mask. In such cases, the oxidation process may not be effective enough.

Anisotropic Etching

The first stage of anisotropic dry etching involves the deposition of a passivation layer, which is chemically inert and prevents the etching of the sidewalls. This layer is sputtered on the substrate after the etching is completed, and is usually C4F8. Without the passivation layer, ions would react with the substrate as they advance deeper into the substrate. This process repeats over again, resulting in small undulations in the sidewalls and isotropic steps.

Another anisotropic dry etching technique is reactive ion etching. This method uses plasma to etch materials and is most suitable for manufacturing nanowire arrays and developing transistor devices, which are widely used in electronic sensors. This process also produces vertical sidewall profiles. However, this technique is not yet widely used due to technical issues. The disadvantages of anisotropic dry etching include low selectivity, and difficulty in controlling CD.

The process of dry etching is characterized by the balance between chemical and physical etchants. Several parameters of the dry etching process can be changed to alter the anisotropy of the etching. The chemical part of this method is highly anisotropic, while the physical part of the process is isotropic. A combination of both chemical and physical etching can produce sidewall shapes that otherwise would not be possible.

Another variation of anisotropic dry etching is cryogenic dry etching. In this process, the temperature of the substrate is cooled to a very low level, typically 175 K, which increases the chemical stability of the silicon oxide film. This reduces the flow of SF6 and oxygen gas, thereby reducing the risk of a chemical reaction occurring. The low temperature also allows the etch floor to be removed without the use of passivating films.

The present invention provides an anisotropic dry etching process that forms a highly etched structure with a high aspect ratio, typically 10:1. The inventive anisotropic etching process also exhibits a fast etchant rate, preferably from eight hundred to ten thousand A/min. Further, the aspect ratio of the anisotropic dry etching process is greater than ten, which is preferred in this process.

Wet and dry etching are similar techniques for the removal of substances from surfaces. The difference is in the type of material to be removed. Dry etching uses chemicals in the liquid phase, while wet etching requires an immersion tank and a spray system. It is safer than wet etching, and allows greater selectivity. A wet etching process also uses the same chemistry, but the chemical solution is much easier to handle.

The etch rate is constant at 30mT and linear for all power densities between 180mW/cm2 and 320mW/cm2. At higher power densities, the chemistry of gold chlorides may become unstable, thereby impairing the process. This may ultimately result in increased deposition of debris on the sample surface. Further, a high power density may also cause an increase in etching debris on the surface of the gold film.

Reactive ion etching (RIE) is a critical step for the manufacturing of microelectronic devices. This process exposes the surface of the semiconductor to ions, causing damage and surface contamination that can degrade the quality of the material. The etching rate can be increased by changing the composition of the plasma, and the conditions of the etching chamber can affect the process of defect formation.

Another method of anisotropic dry etching is called reactive ion etchanting. Reactive ion etching combines chemical and physical etching to create high-resolution images. It is commonly used in PCB manufacturing, where it can create recesses and forms in the surface. If a pattern is desired, the etched material can be modified by removing excess layers.

What are carrier wafers and why are they used for dry etching?

Carrier wafers, also known as handling wafers or process wafers, are typically used in semiconductor processing as support structures for other more fragile or smaller wafers. These carrier wafers are made of the same material as the standard semiconductor wafers (most commonly silicon), but they don't have any devices or circuits fabricated on them.

The reason why carrier wafers are used in dry etching processes is mainly for the following reasons:

-

Protection: Carrier wafers provide physical support to the device wafers, helping to prevent any potential damage during the dry etching process. This is especially important when dealing with thin or fragile device wafers.

-

Uniformity of Etching: The use of carrier wafers can improve the uniformity of etching across the device wafer. This is due to the fact that the carrier wafer can help distribute the etching plasma more evenly across the device wafer.

-

Size Compatibility: Often times, the device wafers being processed are smaller than the size of the etching chamber. Using a carrier wafer that is the correct size for the chamber can help to ensure that the device wafer is properly centered and that the etching process occurs correctly.

-

Cost-effectiveness: Carrier wafers are reusable, which can reduce the overall cost of the etching process. Since they don't contain any valuable devices or circuits, they can be cleaned and reused multiple times without worry of damaging any valuable material.

In essence, carrier wafers are essential for certain semiconductor processes like dry etching, helping to ensure the process is carried out effectively, uniformly, and safely.

Sapphire Substrates Used as Carrier Wafers for Dry Etching

Sapphire wafers can be used as carrier wafers in the dry etching process for a few reasons.

Sapphire is a single-crystal form of aluminum oxide (Al2O3) which is extremely hard, chemically stable, and has excellent thermal conductivity. This makes it suitable for supporting other wafers during processing.

Here's how sapphire wafers are used as carrier wafers in dry etching:

-

Size Adaptation: Sapphire carrier wafers can be made to match the size of the etching chamber. This helps ensure that smaller device wafers, which might not be the same size as the etching chamber, are correctly positioned and that the etching process occurs properly.

-

Thermal Management: Sapphire's high thermal conductivity helps dissipate heat generated during the etching process, reducing the risk of heat damage to the device wafer.

-

Chemical Resistance: Sapphire wafers are chemically inert, meaning they don't react easily with other substances. This is especially important in dry etching processes, which often involve highly reactive plasma. The sapphire carrier wafer won't be affected by the etching process itself, protecting the device wafer and ensuring that the carrier wafer can be reused.

-

Protection and Support: Sapphire wafers provide physical support to the device wafers, which might be thinner or more fragile. The hardness and mechanical stability of sapphire helps to protect the device wafer from any potential damage during the etching process.

-

Transparency: Sapphire is transparent to many wavelengths of light, including those used for alignment and inspection in photolithography, which can be a crucial part of the process before or after etching. This can allow for easier monitoring and control of the process without needing to remove the device wafer from the carrier.

In conclusion, the properties of sapphire, such as its thermal conductivity, chemical resistance, and hardness make it an excellent choice for a carrier wafer in dry etching processes.

Fused Silica Substrates Used as Carrier Wafers for Dry Etching

Fused silica, also known as fused quartz, is a noncrystalline (glass) form of silicon dioxide (SiO2). It's highly pure, has a very low thermal expansion coefficient, excellent thermal shock resistance, and is resistant to most chemicals, making it a good candidate as a carrier wafer in dry etching processes.

Here's how fused silica wafers are used as carrier wafers in dry etching:

-

Size Adaptation: Similar to other carrier wafers, fused silica wafers can be fabricated to match the size of the etching chamber. This ensures that smaller device wafers are correctly positioned, which is important for the etching process to be carried out correctly.

-

Thermal Management: The low thermal expansion coefficient and excellent thermal shock resistance of fused silica help to manage heat generated during the etching process, reducing the risk of heat damage to the device wafer.

-

Chemical Resistance: Fused silica wafers are chemically inert, meaning they don't react easily with other substances. This is important in dry etching processes, which often involve highly reactive plasma. The fused silica carrier wafer won't be affected by the etching process itself, ensuring that it can be reused, and it won't introduce contaminants into the process.

-

Protection and Support: Fused silica wafers provide physical support to the device wafers, which might be thinner or more fragile. The mechanical stability of fused silica helps to protect the device wafer from potential damage during the etching process.

-

Transparency: Fused silica is transparent to a wide range of wavelengths, including ultraviolet (UV) and infrared (IR) light. This can be important for processes that involve photolithography or inspection, as the device wafer can be aligned or examined without needing to be removed from the carrier.

-

Flatness: Fused silica wafers can be made very flat, which can be critical for certain processes where the flatness of the wafer can affect the uniformity of the etching.

In conclusion, the properties of fused silica, such as its thermal stability, chemical resistance, and transparency make it an excellent choice for a carrier wafer in dry etching processes.

What Industries Use Carrier Wafers for Dry Etching?

Carrier wafers are used in several industries that rely on dry etching processes. These industries often involve designing and fabricating microdevices, nanoscale structures, or integrated circuits. Here are some of the primary industries where carrier wafers for dry etching are used:

- Semiconductor Industry: This is the primary industry that uses carrier wafers. Semiconductor manufacturers utilize dry etching to produce integrated circuits, microchips, and other electronic components.

- Micro-Electro-Mechanical Systems (MEMS) Industry: MEMS are miniature devices with elements ranging in size from 1 to 100 micrometers. They're used in many sectors, including automotive, healthcare, consumer electronics. Dry etching is essential for fabricating these tiny structures.

- Nanotechnology and Nanofabrication: In nanotechnology, dry etching is often used to create nanoscale structures. These may be used in various applications, from medical devices to materials science.

- Photonics and Optoelectronics: These industries involve the use of light (photons) for various applications, such as telecommunications, information processing, and sensing. Dry etching is used to fabricate components like waveguides and photonic crystals.

- Solar Energy: In the solar industry, dry etching is used to fabricate solar cells, particularly in creating thin-film photovoltaic devices.

- Bioengineering and Biotechnology: In these fields, dry etching might be used to create microfluidic devices or biosensors.

- Telecommunications: The telecom industry utilizes dry etching to produce components for optical communication systems, including waveguides and optical switches.

These are just a few examples; any industry that relies on microfabrication or nanofabrication techniques will likely use dry etching and, therefore, carrier wafers.

Press Release

Benefit from Superior Quality and Performance with UniversityWafer, Inc's Substrates for Dry Etching

May 17, 2023 - Boston, Massachusetts - UniversityWafer, Inc, a leading provider of semiconductor wafers and substrates, proudly highlights the advantages of its cutting-edge substrates for dry etching processes. These substrates are designed to deliver exceptional performance, reliable results, and superior value to clients in the semiconductor industry.

Our product portfolio includes a range of carrier wafers, such as sapphire and fused silica substrates, optimized for dry etching applications. These substrates, manufactured with precision and stringent quality control, are designed to offer numerous benefits:

Enhanced Thermal Management: Our substrates are selected for their superior thermal properties. Whether it's the high thermal conductivity of our sapphire wafers or the low thermal expansion coefficient of our fused silica wafers, we've got your heat management needs covered.

Chemical Resistance: UniversityWafer's substrates are chemically inert, ensuring they won't react with the reactive gases typically used in dry etching processes. This guarantees the integrity of your device wafer, while also ensuring our carrier wafers can be reused, reducing overall process costs.

Protection and Support: Our substrates provide essential physical support to device wafers, safeguarding them from potential damage during the etching process. Their excellent mechanical stability makes them the perfect choice for handling thinner or more fragile wafers.

Size Adaptation: We offer wafers tailored to fit the size of your etching chamber, ensuring correct positioning and uniform processing.

Transparency: With substrates that are transparent to a wide range of wavelengths, including ultraviolet and infrared, inspection and photolithography processes are made easier.

"Semiconductor manufacturers demand superior performance, reliability, and cost-effectiveness in their etching processes," said Chris Baker, CEO of UniversityWafer, Inc. "Our sapphire and fused silica substrates are designed to meet these demands head-on, providing a high-quality solution that benefits our clients."

About UniversityWafer, Inc: UniversityWafer, Inc. is a premier supplier of high-quality semiconductor wafers and substrates. With a commitment to innovation, quality, and customer service, UniversityWafer, Inc. supports industries and researchers worldwide with the materials they need to drive the future of technology.

reactions at a low cost. This process uses small quantities of chemicals and electricity to produce high-resolution structures. Manufacturers can gain advanced resolutions by using dry etching instead of expensive photolithography tools. Dry etching has a variety of benefits for manufacturers, including high aspect ratio structures and less expensive equipment.

reactions at a low cost. This process uses small quantities of chemicals and electricity to produce high-resolution structures. Manufacturers can gain advanced resolutions by using dry etching instead of expensive photolithography tools. Dry etching has a variety of benefits for manufacturers, including high aspect ratio structures and less expensive equipment.