I am following a reference to make "Improving Contact Interfaces in Fully Printed Carbon Nanotube Thin-Film Transistors”

This describes t what I need: The process used for fabricating the printed CNT-TFTs on a Si wafer with 90 nm thick SiO2 is illustrated in Figure 1. The substrate was first cleaned with acetone, IPA and deionized (DI) water, followed by oxygen plasma (100 W) for 3 min.

Can you point me in the right direction which product I should buy/ This is not my area of expertise.

Silicon Wafers for Thin-Film Transistor Research

Cabon Nanotube Thin-Film Transistor

A PhD candidate requested a quote for the following.

UniversityWafer, Inc. Quoted:

Item Qty. Description

FW06. 25/50 Silicon wafers, per SEMI Prime, OxP/EOx 4"Ø×525±25µm, p-type Si:B[100], Ro=(5-10)Ohmcm,

TTV<5µm, Bow<30µm, Warp<30µm, One-side-polished, back-side Alkaline etched (both with oxide), Thermal Oxide: 90±5nm, SEMI Flats (two), Sealed in Empak or equivalent cassette.

Reference #240814 for specs and pricing.

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

Passivate Thin Film Transistor

An assitant professor requested a quote for the following.

I'm looking for a Non-doped spin-on glass (SOG) material that can be spin-coated with a nanometer thickness of (80-100 nm). Can I get this thickness using your products? If so, could you help me prepare a quotation for that product? If not, could you help me suggest the most-relevant product? I am planning to use it to passivate my thin film transistor and I want to mitigate the effects of the SOG on the bottom material. If you have any information on that would also be appreciated.

Reference #275451 for specs and pricing.

Thermal Oxide Coated Silicon Wafers

Researchers have used our prime grade silicon wafes with 300nm of wet thermal oxide for their thin-film transistor projects.

It can be tough finding the right spec in the right quantity and price. UniversityWafer, Inc. is there to help you soure the materials you need and in the quantities that you want.

Thermal Oxide Coated Silicon Wafers Used to Research Excess Polymer in Single-Walled Carbon Nanotube Thin-Film Transistors: Its Removal Prior to Fabrication Is Unnecessary

Researchers used UniversityWafer's Prime Grade Silicon wafers with 300nm of thermal oxide have been used for this research.

Contact us for the exact spec.

Gate Oxide In Thin Film Transistor

A postdoc requested a quote for the following:

The SiO2 layer is used as gate oxide in thin film transistor in my reasearch. Its leakage current must be as low as possible (<10nA). The requirments of SiO2 wafer are as follows:

1. Thickness: 100nm-200nm SiO2;

2. Method: Dry,not wet method;

3. Diameter: 100mm (4 inch) or other;

4. Type: n-type or p-type;

5. Orientation: <100>;

6. Resistivity: 1-10 ohm-cm;

7. Surface: one side Polished;

Can you offer the SiO2 wafer as stated above?

UniversityWafe,r Inc. Quoted:

100mm P(100) 1-10 ohm-cm SSP 500um with 100nm of Oxide on both sides

Reference #159939 for specs and quantity.

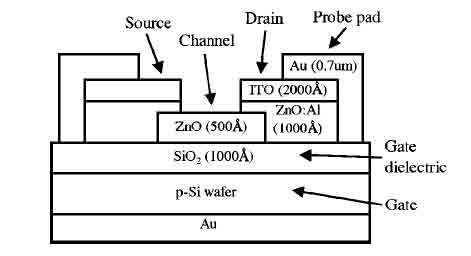

Zinc Oxide Substrates for Thin Film Transistor

A materials engineer requested a quote for the following.

I am trying to make a thin film transistor with commercial zinc oxide that I can compare with results with our MBE grown zinc oxide.

I was referring to this setups:

- ZnO(50nm) on Fused Silica 10x10x0.5mm

- ZnO(100nm) on Fused Silica 10x10x0.5mm

Our TFT model might look like this:

So I was wondering if the ZnO on the fused silica meant ZnO on a p-type wafer that has grown some thermal silica on it and then ZnO on top of it (they would be the layers p-Si, SiO2 and ZnO on the figure above). Or it is just fused silica?

Also, do you have any spec sheets on the ZnO for different substrates?

UniversityWafer, Inc. Quoted:

- ZnO(50nm) on Fused Silica 10x10x0.5mm

- ZnO(100nm) on Fused Silica 10x10x0.5mm

Reference #251773 for specs and pricing.

Thin FilmTransistor Device Fabrication?

Understanding substrate parameters

Examining substrate parameters for thin film transistor devices, particularly on silicon substrates, involves considering factors like doping concentration, orientation, type, and thickness.

Sizing substrate standards

I’m thinking about silicon substrate specifics for TFT devices: orientation at (100), thickness of 500 µm, resistivity between 0.001-0.005 ohm-cm, and thick p++ doping for gate electrodes.

In research labs and small‐scale prototyping, it is quite common to fabricate TFTs on a heavily doped (degenerately doped) silicon wafer that then serves as a “global” back gate. While there can be variations from lab to lab, the most frequently used specifications are roughly as follows:

-

Type and Doping Level

- Heavily doped (degenerately doped) p-type or n-type silicon

- Typical resistivity: on the order of 10⁻³ – 10⁻² Ω·cm (ensures the substrate can act as a gate electrode)

-

Orientation

- Usually 〈100〉 orientation (industry standard and widely available)

-

Wafer Thickness

- Often around 500 μm for mechanical stability (though thinner wafers exist)

-

- 4 in, 6 in, or even 8 in wafers, depending on the facility

-

Surface Oxide

- Many labs either purchase wafers with a thermal oxide pre-grown (often 100 nm – 300 nm thick) or they grow/deposit their own insulating layer.

- This oxide (or an additional deposited dielectric) serves as the gate dielectric, with the heavily doped silicon acting as a global back-gate.

These specifications enable a simple TFT process flow in which the silicon wafer doubles as a bottom gate electrode (through its degenerate doping) and as a mechanical support. By adjusting the doping, oxide thickness, and (optionally) adding further dielectric layers, researchers can tune the electrical characteristics of the test structures.

Substrates for Thin Film Transistor Research

A scientist requested a quote for the following TFT project.

I am looking for 200 mm p-type doped silicon wafer with 100nm wet thermal oxide (such as ID 3599 of you web page) for TFT applications. Would you be able to propose additional process on the wafers such as oxyde removal on the back side and dicing in 20x15 mm2 chips?

Please reference #269693 for pricing.

Silicon Wafers Coated With SiO2 Thin Film for Thin Film Transistor Application

A Nano Optoelectronics Researcher requested a quote for the following.

Do you have Si wafer SiO2 thin film for thin film transistor application purpose. If have, what method is used to deposit SiO2?

Grade: prime CZ

Diameter: 3” Silicon Wafer

Resistivity: <0.005 ohmcm

Layer: SiO2 (100, 150nm thickness).

Singe slide polished.

25pc per spec.

- N++ Si (111) As doped.

- N++ Si (100) As doped

- P++ Si (100) Boron doped

- P++ Si (111) Boron doped

Reference #243560 for specs and pricing.

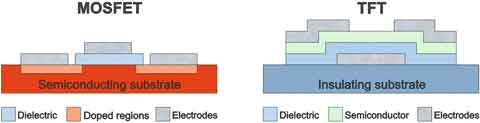

What are Thin Film Transistors (TFT)?

A Thin Film Transistor (TFT) is a type of field-effect transistor. The name comes from the fact that the transistor's layer is quite thin compared to the plane of the device. The transistor is grown on a supporting substrate, most  commonly glass. These are commonly used in liquid-crystal displays.

commonly glass. These are commonly used in liquid-crystal displays.

Thick-film transistors

Thin-film transistors are one of the most common flexible electronic components. They are widely used in applications such as conformable radio frequency identification (RFID) devices, flexible displays, and smart textiles. Their unique properties are defined by the semiconductor material used in the manufacturing process. These properties include mechanical and electrical properties.

Thin-film transistors can be made from many different semiconductor materials, such as silicon and cadmium selenide. However, recent advances have given engineers the chance to experiment with other materials, such as organic semiconductors. Such materials are known as organic thin-film transistors. In order to make these transistors, transparent electrodes are used. Indium tin oxide, for instance, is a common choice for this application.

Graphene can also be used in TFTs. The use of graphene allows for a device with a large channel area. Graphene, for example, has a large area and a large mobility. It has been shown that a TFT made from rGO can achieve a high intrinsic carrier mobility.

The process used for making a TFT is called physical vapor deposition, which involves using low temperatures and a clean atmosphere. Sputtering is another common method of deposition in TFTs. It has helped researchers and developers overcome many technical challenges. This article will introduce some of the basic concepts of TFTs.

Thin-film transistors can be used in many different types of electronics. These include display screens, imaging arrays, and a wide variety of sensors.

Organic semiconductors

One of the major challenges of materials chemistry is the development of new organic semiconductors. These new materials must be air-stable and have the ability to switch transistors with a positive or negative gate voltage. Developing these new materials is an extremely challenging project. This paper describes one important study on organic TFTs.

The main goal of this research was to develop a process that produces a thin film of organic semiconductors. This method of production can increase the size and speed of devices. In addition, it can be scaled up. This breakthrough could usher in a new era of organic thin film transistors.

The process of solution processing allows the fabrication of devices with high mobility in ambient air and low contact resistance at 20 V. As a result, these devices exhibit excellent electrical performance. Furthermore, the yields are high, allowing the statistical analysis of a large number of organic TFT devices. The study also found that the electrical performances of these devices are highly uniform.

Organic thin film transistors can be made with several different materials such as silicon, cadmium selenide, and zinc oxide. However, recent advances in the field of electronics have allowed engineers to experiment with different organic materials to create new thin film transistors. The best example of this is Indium Tin Oxide, which is commonly used for video display panels.

The researchers used a Zeiss Axioplan optical microscope with a built-in camera to observe the electrical properties of the devices. In addition, they used a semiconductor parameter analyzer (Agilent B1500A) to measure current-voltage characteristics of each device. These measurements were performed at room temperature in ambient conditions.

Neodymium Nitride Thin-Film Transistors

Neodymium nitride (Nd) thin-film transistors are semiconductor devices that are designed to produce high-current outputs. They are made of an amorphous silicon or Nd-doped indium-zinc oxide (IZO) layer, a metal or alloy-based source-drain interface layer, and a dielectric material.

The thickness of the Nd-IZO film has a large impact on the device's performance. The thicker the film, the more effective the transistor will be. In addition, the thickness of the Nd-IZO layer also has a strong effect on the device's mobility.

The process of making Nd-IZO thin-film transistors involves an etching process. A first metal layer, generally pure aluminum or an aluminum-neodymium alloy, is deposited on the substrate. A second, patterned layer is then deposited on top of the first one. These layers are laminated one after another in a specific order. This process produces an n+ a-Si layer, which in turn forms the transistor's gate electrode.

The thin-film transistor is typically fabricated on an insulating substrate. It has a channel region, a source and a drain region, and a gate electrode. The source and drain regions are electrically isolated from each other, and an insulating layer is fabricated on top of the n+ a-Si layer.

Video: Thin Film Transistors Explained

How Thin-Film Transistor Technology Is Used in Flat Panel Displays

The technology behind thin-film transistors is used in flat panel displays. They are made by depositing a semiconductor and dielectric layer over a glass substrate. These devices have dominated the display market for a decade. These transistors are the on/off switches for individual pixels, which combine to form the picture you see on your screen. The process of forming these devices is known as thin film fabrication. This process is a highly complex one.

These devices use a process called physical vapor deposition (PVD), which requires low temperatures and an inert atmosphere. In the manufacture of TFTs, the conductive film is deposited using sputtering. A company called Angstrom Engineering has worked closely with researchers and developers to overcome the many challenges of making thin-film transistors. The technology is currently being developed for applications in high-speed, high-density and low-power devices, as well as in a wide variety of industries.

One of the most important applications for thin-film transistors is in LCD displays. These display devices use embedded thin-film transistors to improve image stability and reduce crosstalk between pixels. TFT technology is widely used in many color LCD TVs. TFT panels are also used for general radiography and digital radiography. In addition, AMOLED screens also use a TFT layer. In the future, they may even be used in smartwatches, wearable electronics, and other products.

Unlike CMOS semiconductors, thin-film transistors have a low-temperature process. This process involves depositing a thin film of materials on a polymeric substrate. Consequently, it is possible to manufacture TFTs on large, flexible substrates at a relatively low temperature. This technology has the potential to revolutionize the display industry and is being researched by researchers and developers around the world. This is the latest in semiconductor technology, and is an important tool in the fabrication of modern electronic devices.

Several other semiconductor materials can be used for thin-film transistors, including silicon, cadmium selenide, zinc oxide, and inorganic materials. The use of these materials has led to the development of organic thin-film transistors. In addition to CMOS chips, this technology is also being used for video displays and imaging arrays. A number of other applications have been developed to integrate the technology into wearable devices.

In addition to semiconductor materials, thin-film transistors are made of a variety of materials. Silicon, cadmium selenide, and zinc oxide are all common materials used for TFTs. But recent advancements have allowed engineers to experiment with organic materials and produce a thin-film transistor called an "organic" transistor. The transistors made from these materials are used in video display panels, imaging arrays, and in mobile and wearable applications.

Thin-film transistors are widely used in flexible electronic products. They are also used in wearable and ultra-light devices. They are a key component of active matrix liquid crystal and organic light-emitting diode displays. However, some problems with these devices have been solved by scientists who have designed hybrid thin-film transistors with high-K amorphous silicon. These semiconductors are widely used in smartphones and tablets.

A new approach to manufacturing TFTs is a method of combining multiple materials on the same substrate. Inkjet-printed rGO sheets can be used as channel materials, and they have electron and hole mobility of 365 cm2/V/s. A novel synthetic pathway opens the door for the fabrication of patterned MO semiconductors. This technique is particularly useful for high-volume electronics and displays. This technology is also used in high-tech gadgets.

These devices can be fabricated with a variety of materials. For example, the most common material is a semiconductor, such as a silicon semiconductor or a graphene. A metal-oxide substrate, such as a silicon-based chip, can be used to create a thin-film device. Its high-quality metal-oxide material can be made into a flexible substrate by spin-coating.

A new technology known as source-gated transistors is being developed that promises to drastically increase the number of transistors. They are designed to be made as small as possible with a thin-film substrate and can be fabricated in a wide variety of ways. Aside from making thin-film devices, these new technologies also have a positive impact on large-area electronics. The invention of this technology has paved the way for the development of displays in mobile phones, televisions, and high-resolution TVs.