Semiconductor Technology | Substrates for Research & Production

Semiconductor Technology

Electronic devices are mainly made up of a small but sophisticated integrated circuit that is capable of handling some specific or general instructions. This integrated circuit has two main parts i.e. a small fragile silicon chip and an external package covering the chip. The external package provides a way in which the chip can interact with other external peripherals. In ICs, the electronic components such as transistors are built on the surface of a wafer as opposed to having to assemble ready-made devices and connecting them in a given way through soldering. The technology behind semiconductor devices is complex owing to the technical processes that are involved.

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

How Do You Determine if a Material is a Semiconductor?

To determine if a material is a semiconductor, several methods and techniques are employed. These methods generally focus on identifying the electrical and structural properties of the material. Here are some common methods used:

Electrical Conductivity Measurement: This is the most direct method. Semiconductors have electrical conductivity between that of a conductor and an insulator. By measuring the electrical conductivity at different temperatures, one can infer if a material is a semiconductor. The conductivity of semiconductors increases with temperature, which is opposite to the behavior of metals.

Hall Effect Measurement: This technique involves applying a magnetic field to the semiconductor and measuring the Hall voltage that is developed. This method not only confirms the semiconductor nature of a material but also helps in determining whether it is a n-type or p-type semiconductor based on the sign of the Hall coefficient.

Energy Band Gap Measurement: The band gap – the energy difference between the valence band and the conduction band – is a key characteristic of semiconductors. Techniques such as optical absorption spectroscopy, photoluminescence, and electron spectroscopy can be used to measure the band gap.

X-ray Diffraction (XRD): XRD is used to analyze the crystal structure of the material, which is important in semiconductors for understanding their electronic properties. A well-defined crystal structure is often necessary for a material to function effectively as a semiconductor.

Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM): These methods are used to study the surface and internal structure of the material at a microscopic level. They can provide insights into the quality of the semiconductor material, including defects and impurities.

Four-Point Probe Method: This method is used to measure the resistivity and sheet resistance of semiconductor materials. It is more accurate than the simple two-probe method as it eliminates the effects of contact resistance.

Seebeck Effect Measurement: This involves measuring the voltage developed in the material when there is a temperature gradient across it. Semiconductors exhibit a significant Seebeck effect, which is used in thermoelectric applications.

Each of these methods provides different pieces of information about the material, and often, a combination of these methods is used to comprehensively determine if a material is a semiconductor and to understand its properties in detail.

Semiconductor Elements

Semiconductors are elements characterized by having a resistivity and conductivity value that is between that of conductors and insulators. Semiconductors are desired as it is possible to modify their resistivity values by introducing impurities to the material. Common impurities that can be used are Boron (P-type), Phosphorous, or Arsenic (N-type) silicon. Most semiconductor manufacturers do buy wafers that are pre-doped with either n-type or p-type impurities at levels of one doping atom per ten million silicon atoms. The percentage concentration of a dopant in a semiconductor material ranges from 0.000001 percent to 0.1 percent. With this, sections of accurate resistivity values can be found.

Crystal growth techniques include the Czochralksi process, the Bridgeman, or the Float Zone method. Currently, three-hundred-millimeter diameter wafers are produced using the Czochralksi approach. Large wafers are advantageous as they result in increased productivity, increased profits, and lower costs. This is because many processors can be made from a single chip. Despite this, semiconductor technologies generally do need high capital investments as it is quite expensive.

a. Semiconductor device fabrication

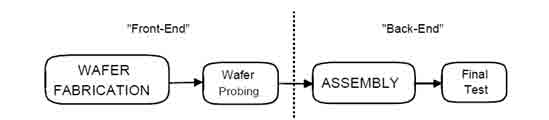

The process of making semiconductor devices can be grouped into two main stages. The first step involves fabricating the wafer while the second is processing and packing the die.

Figure 1: A flowchart showing the manufacturing sequence of Integrated circuits.

Wafer fabrication

Similar integrated circuits are made on each wafer as a result of the various processes that have to be done. Each process that is taken while fabricating the wafer is significant as it either adds or modifies the layers present. A summary of the steps is presented below though some of them may be repeated.

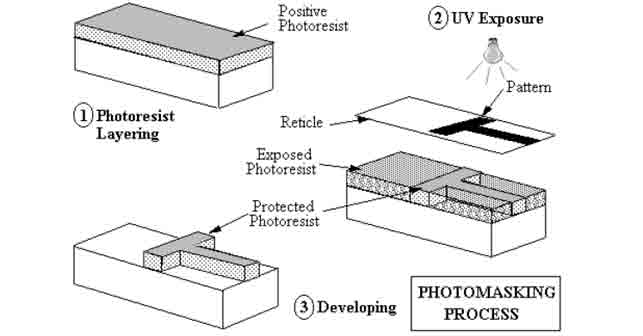

Photo-masking - This process is done to shape the various components. A wafer that has resin applied on its surface is exposed to light with the aid of a specific mask. The light has the effect of softening some parts of the wafer thus the desired geometry can be obtained after the soft areas have been washed away. This operation has to be repeatedly undertaken until the desired results are achieved.

Figure 2: The Photomasking Procedure

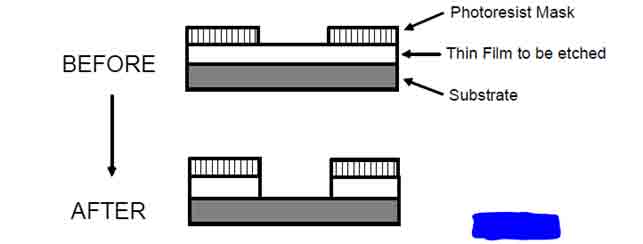

Etching

This operation is done to eliminate thin films of the material and can be achieved by employing either liquid or gaseous compounds. At the end of this procedure, a given circuit pattern is obtained that has been specified in photo-masking. This process has to be done when deposition takes place to a layer that has to be etched.

The process of etching

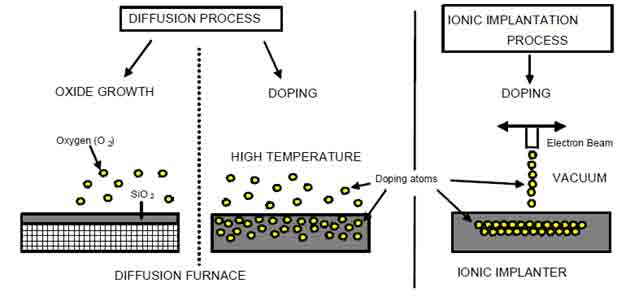

Diffusion

This operation is done to introduce dopants to the semiconductor material. Alternatively, a thin oxide-based layer may be introduced to the semiconductor surface using this method. A wafer is placed inside a furnace then doping gases are introduced inside the furnace.

Ionic implantation – entails the use of an electron beam to introduce dopants to the semiconductor material. This method makes it possible to implant dopant's some depth inside the silicon material allowing for better control of the primary parameters. It is easier to achieve the doping of semiconductors using this method as compared to diffusion though at a higher cost.

Figure 4: A comparison between Diffusion and Ionic Implantation Process

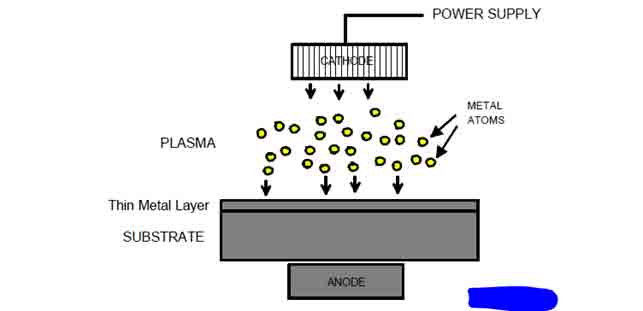

Metal Deposition

This process aids in providing electrical connections in the different cells of the integrated circuit. Evaporation or sputtering methods are used to deposit the metal to the desired paths in the circuit. Sputtering involves creating a plasma with argon atoms that bump on a target surface ripping metal atom from the target. Projection of atoms happens in almost every direction though most of the atoms undergo condensation on the substrate surface.

Figure 5: The metal deposition process

Passivation

A layer of silicon oxide or silicon nitride is used to seal the wafer preventing contamination or moisture attack.

Back-lap

This step involves a reduction in the wafer thickness.

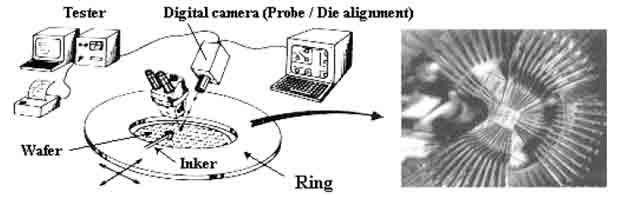

II. Wafer Probing

In this step, the functionality of the device is carried out. All the electrical tests have to be done using special microprobes. Wafer probing is done in either process parametric tests or full wafer probing test. Process parametric tests are done on some samples while the later has to be done on the end product on all dies.

Figure 6: An illustration of the wafer probing process

The bad chips are labeled using a black dot to facilitate the separation of the bad from the good dies. The damaged dies are then studied to ascertain the root cause of the failure and possible correction strategies. The yield value is a percentage expression of functional dies existing in a single wafer. III.

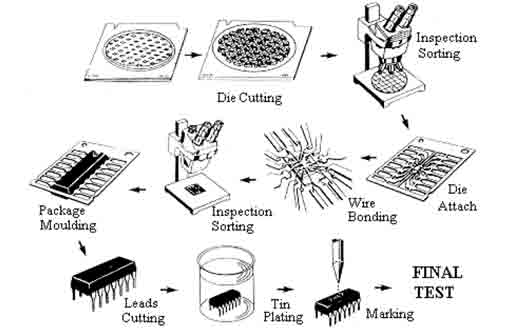

The Assembly process

Figure 7: An illustration of the assembly process

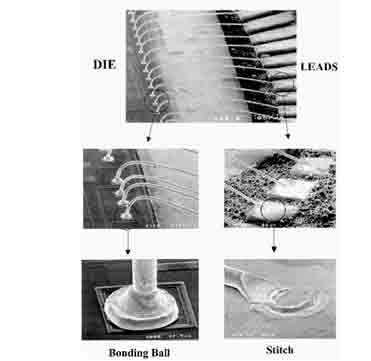

Thin wires with diameters of about thirty-three microns are used to establish the connection of the chips to the outside world. Through these connections, various signals may be fed to the chip while respective outputs are obtained. A wire bonding procedure best illustrates the wire connection process.

Figure 8: Wire bonding procedure

After the bounding operation, a ceramic or plastic casing has to be placed on the chip to make handling of the chip easier and also protect the chip from external interferences and shock. The place where the chip is to be used does have a significant impact on the shape and size of the package to be used. After these steps, a traceability code has to be printed on the casings' top surface in most cases to provide manufacturing details.

What are Some Different Types of Semiconductor Lasers and Their Applications

There are many types of semiconductor lasers, and they can be classified into several types based on their wavelengths and bandgap energies. In this article, we'll cover some of the main types of semiconductor lasers, their applications, and their substrates. Whether you're looking for a laser for medical use or want to make a high-speed, ultra-compact laser, this guide will help you understand the different types of semiconductors and their capabilities.

![]()

What are Semiconductor Laser Applications?

Semiconductor lasers are a promising new generation of light sources, demonstrating promise in several areas. Their emission wavelengths can be precisely tailored to a desired wavelength, and their spectral range is determined by the energy of the bandgap, the gap between the valence and conduction bands. Different semiconductor alloys allow for tuning the bandgap and a semiconductor laser can cover a wide range of wavelengths, including red, near infrared, and blue-ultraviolet.

The design of the wavelength of a semiconductor laser is determined by the size and shape of the optical system used to produce the beam. For the first step of beam shaping, the semiconductor laser diode is collimated. This step is followed by other beam shaping processes. These beam shaping processes are influenced by misalignment of the collimator. Misalignment of the reflector and collimating lens is particularly problematic. A misaligned reflector can significantly reduce the beam size and coupling efficiency.

Semiconductor lasers with optical feedback exhibit a rich variety of chaotic dynamics. Using numerical calculations of rate equations, they can be used to understand chaotic bifurcation and the corresponding oscillation modes. Various parameters, such as the external mirror reflectivity, are crucial to understanding the behavior of the laser. One of these is the period-1 frequency, which is closest to the relaxation oscillation. Increasing the external reflectivity causes period-2 and even chaotic states.

The high-power single-emitter array semiconductor lasers reduce the beam size and require multiple optical paths. The beam shaping system uses polarization, fiber bundle, or spatial combination to manipulate the laser output. For example, in one study by Liu et al., multiple single-emitter sources were combined in steps. The beam was then combined with 11 mirrors and a polarization beam combiner.

What are the Bandgap Energies of Semiconductor Lasers?

The center wavelength of a semiconductor laser depends on the bandgap energy of its active layer semiconductor. While bandgap energies are similar for all types of LDs, the spectral range is different. Hence, it is important to understand the differences in bandgap energies between different types of LDs. This can be achieved by tuning the semiconductor alloy's bandgap energy.

To calculate the gain, first calculate the carrier density, N, of a 1.3-mm InGaAsP active layer. The carrier density is equal to one x 1018 cm-3. As N increases, optical gain also rises. The peak value of the gain shifts upwards, toward higher photon energies. This population inversion also allows for rapid increases in optical gain. This is the reason why the gain of semiconductor lasers is so important in applications.

Semiconductor lasers are solid-state devices based on a semiconductor gain medium. Their wavelengths are determined by measuring the electrical current passing through the active region. Because semiconductors have a molecular structure similar to the human eye, their wavelength is approximately equal to their effective masses. Furthermore, they are capable of tuning over a few nanometers in wavelength. This means that they are highly flexible in the production of high-quality lasers.

One way to engineer semiconductor lasers with the desired bandgap energy is by engineering the material's lattice. This process involves varying the stoichiometry of the semiconductor. The resulting blue laser diodes, for example, are made by combining AlN and InN. Red laser diodes are created using a blend of AlAs and GaAs. Matching the lattice to the base semiconductor material can engineer almost any bandgap energy.

What is Collimation?

In order to produce a narrow beam of light from a semiconductor laser, the diode's output facet must be near the collimation lens. This distance must be small enough to minimize the divergence. After collimation, the beam will have a diameter equal to the full divergence angle times the lens's focal length. A common collimating lens is an anamorphic lens.

For this purpose, a rounded cross-section of the beam is preferred to an elliptical one. To achieve this, a collimating lens set with two orthogonal lenses is used. The focal lengths of the lenses are related to the divergence of the laser beam in the fast axis and slow axis, respectively. In order to achieve a high-quality beam, the lenses must have acylindrical shapes.

These collimating lasers are widely used in communication research. Their small size, high power and efficiency make them ideal for high-energy laser weapons. Because they are small in size, they are also well concealed. Further, they can be used for laser ranging, lidar, and guidance. Further, they are suitable for a wide variety of applications. The LRD-0852 Series is available in FDA-compliant laser driver and as a compact O.E.M. component.

Because lasers are point sources, collimating distant objects is a difficult problem. The size of the source has to be considered as well. For example, a point source with radius y1 will have maximum ray angle th1 and maximum divergence angle th2 = y1/f. The relationship between the beam radius and the divergence angle is reciprocal, which means that a laser beam with infinite diameter would have a zero ray angle.

What Substrates are Used in Semiconductor Lasers?

Semiconductor lasers are compact and reliable devices that have a direct bandgap semiconductor material for an optical amplifier. They are made from an Indium Phosphide (InP) or Gallium Arsenide (GaAs) substrate and contain elements in Group III and V of the periodic table. The semiconductor materials are grown onto a substrate in layered structures. This book will provide an overview of the process used in the fabrication of semiconductor lasers. It will also discuss the materials that are used in semiconductor lasers.

The materials used in semiconductor lasers are known as semiconductor diodes. In the development of semiconductor lasers, silicon is not a common material. This is because silicon is not a direct bandgap semiconductor. Therefore, silicon is not a good material for a laser diode. Other semiconductor materials, such as indium gallium disulfide Indium Antimonide (InSb) and germanium disulfide (GaAs) are available.

Substrates for semiconductor lasers are a subset of larger p-n junction diodes. The difference in electrical potential between the n-type and p-type semiconductors creates an injected region, known as an injection laser. Injection lasers are also sometimes called injection laser diodes. They can produce up to 50 watts of continuous wave power. These devices can last for five thousand hours.

A semiconductor laser's structure is a layered, patterned structure. First, a substrate is mechanically polished to 70-100 microns in thickness. Next, a silicon dioxide film is deposited on the surface. Afterwards, the material is chemically etched to form stripes. Then, contact electrodes are applied using an evaporation method. Finally, a laser resonator is made by cleaving the wafer along parallel crystal planes. The completed laser device is then attached to a copper heat sink and a small electrical contact.

Pumping

Aram Mooradian and his team have successfully used the pumping technique to achieve output powers of up to one-W. Pump radiation travels through a gain medium, composed of a highly reflective Bragg mirror at the top and an uncoated semiconductor disk on the bottom. This process, called "codoping," keeps the pump and laser radiation in resonance. Hence, the pump photons are able to achieve a higher peak power than those of a single-photon laser.

In the Ti-sapphire experiment, the semiconductor disk contained six InGaAs quantum wells emitting at approximately 980 nm. The geometry of the pumping laser was optimized for resonant pumping. The quantum-well pumping method, however, required an external lens/mirror combination. This second double pass in the gain medium reflected unabsorbed pump radiation from the disk. Moreover, a plot of incident and absorbed power showed a higher efficacy with quantum-well pumping than with barrier pumping.

In the gas-state laser, the population inversion occurs at discrete energy levels, where the laser has impurities. These isolated levels are difficult to manipulate by direct current injection, but they allow optical pumping. These isolated energy levels lead to stable operating wavelengths. Besides pumping, semiconductor lasers are also used in communications and high-speed printing systems. They also serve as laser pointers and pump sources for solid-state lasers.

Diode-pumped solid-state lasers have higher peak power, but lower efficiency, shorter service life, and much less power. In addition, their service life is also limited and their maximum output power is less than one watt. In contrast, diode-pumped solid-state lasers have higher peak power than single-photon devices. So, the two-photon pumping techniques are complementary. In the same way, the pumping technique reduces thermal induced lensing and birefringence.

What Are the Challenges and Limitations in Semiconductors and Nanophotonics?

To answer the question of What are the challenges and limitations in semiconductors and nanophotoics, we should first look at the measurement techniques that are currently available. Among these methods, we will discuss the EELS method, the QW-SPR, and the numerical simulation. All these techniques can help us understand the behavior of nanophotonic systems. In addition to these measurements, these techniques are also used in several applications.

What are Electron Energy-Loss Spectroscopy (EELS) Meeasurements?

Electron energy-loss spectroscopy (EELS) measurements are sensitive to the electronic state of atoms. The electron-matter excitations that result from EELS measurements can be controlled in a variety of ways, depending on the type of atom. For example, a cold-field emission electron source can provide energy resolution down to 0.3 eV. The zero-loss peak is asymmetric, indicating that electrons are not completely confined to a specific phase.

Monochromatic EELS spectrum imaging was performed at 60 kV, close to the Cherenkov limit in ZnO. Specimens were thinned to 2030 nm to eliminate unwanted retardation losses. A 2048-channel EELS spectrometer was used to collect the band gap and plasmon energy simultaneously. The duration of exposure for each pixel was similar to the limiting time of CCD.

To further improve the precision of EELS measurements, researchers are exploring the use of a new technique called local electronic structure trend correlation. This technique compromises absolute accuracy, but it provides a simple route to nanoscale structure correlation. The resulting EELS measurements provide a quantitative estimate of the free electron plasmon energy. In this way, we can understand the underlying structure of semiconductors and nanophotonics.

Another useful tool for EELS is the ability to map the photonic density of states. EELS phonon microscopy allows researchers to map the spatial distribution of 77 meV vibrational modes. BN101 is an excellent candidate for this task because it exhibits strong anti-bunching and single-photon excitation. This method is not without its limitations, however. So, it's vital to know how to make the most of it.

Quantum well surface plasmon amplifier (QW-SPR)

Modern plasmonics is a dynamic field on the frontier of nanophotonics and semiconductors. Its focus is the phenomena associated with and induced by surface plasmons. This road map provides an authoritative and concise overview of the state of the field. It will be of interest to a broad audience of applied, fundamental, and chemistry researchers.

QW-SPR is a promising approach to studying scattering events, since the wavelength and the intensity of the scattering events are controlled by the wavelength of the electromagnetic beam. Its large evanescent field reduces the SPR sensitivity of small molecules and contributes to the stabilization of the QW-SPR signal. However, it is difficult to realize miniaturization, and thus requires significant research.

The QW-SPR has great potential as an active biosensor. By immobilizing IAV-H3N2 in solution, it was possible to detect the presence of the virus in the solution. Because the inactivated virus's outer shell is completely permeable to PBS buffer, the only component contributing to the refractive index shift is the genetic material and protein capsid. Therefore, the resulting specific shifts could be measured.

The advantages of QW-SPR include high sensitivity and wide dynamic range. The two types of architectures have different disadvantages. Monolithic architectures are more stable in time and produce larger shifts than integrated ones. The full dispersion mapping approach, meanwhile, carries a number of disadvantages, including excessive acquisition time.

A typical QW-SPR experiment using a nanoSPR6 system demonstrates the sensitivity of the device to BSA adsorption. A typical nanoSPR6 experiment yields SNR and DS values of DB=1081x10-4+3x10-4 um-1 and DS=519x10-4um-1, respectively.

Electron Energy Loss Spectroscopy

In order to study the nature of materials, electron energy loss spectroscopy can be used to determine the properties of materials. It can be used to measure the amount of energy lost to a sample by measuring the intensity of its peaks. Several types of losses are available, including plasmon and inner-shell ionizations. The loss rate depends on the composition and density of the sample.

The spectroscopy of electrons in a material offers a window into the properties and processes at the nanoscale. It can simultaneously render images of nanoscale objects at a resolution of subnanometers and correlate spectroscopic information. Among these techniques are TEM and CL. However, TEM and ELS are also useful for examining the optical properties of nanoparticles.

The spectroscopy of electrons at the atomic level is a powerful technique for elemental analysis. Despite being sensitive and high resolution, the technique is limited by the thickness of the sample. This is because it interferes with the interaction between electrons and the sample, reducing the signal-to-background ratio. Further, the sample's thickness limits the ability to detect elemental properties.

To determine the electron energy loss of a sample, EELS methods need to be developed. These techniques require a high-energy electron source. This electron source is typically tungsten in a strong electric field to provide high energy electrons to the sample. The object lens and condenser facilitate the formation of an electron probe. STEM has limited spatial resolution due to lens aberrations.

To overcome the difficulty of measuring EEL spectra with these methods, researchers should develop an improved probe for high-voltage devices. In the past, this method was limited by its size and sensitivity. The HG603U STEM from VG Microscopes offers an increased FWHM with a 0.5 A FWHM. Additionally, the probe's tails are reduced, enabling researchers to view smaller areas and increase peak intensity.

Numerical Simulations

This review outlines some of the fundamental challenges and limitations of numerical simulations of semiconductors and nanophotonic systems. The methods presented are not limited to a single type of system, but are generally designed to solve several different types of problems. For example, if the semiconductors are incorporated into a complex integrated device, numerical simulations of semiconductors are not appropriate. Furthermore, they are not suited for applications in nanophotonics, where two or more types of materials are used.

Surface integral methods (SIE) and boundary element methods (BEEM) solve electromagnetic scattering problems by reducing the complexity of the material's surface boundary to the smallest possible unit. Surface integral methods work well for piecewise homogeneous media. The boundary element method and the SIE method are widely used in nanophotonics, although they have distinct differences. The boundary element method is the most commonly used method for the simulation of semiconductors and nanophotonics, whereas the SIE method is a simpler version.

Surface plasmon resonances exhibit blueshift as the radius decreases. This blueshift phenomenon can be attributed to nonlocal effects and is particularly important for most plasmonic applications. Surface methods require a large amount of computation memory, however, and they must be coupled with a hydrodynamic Drude model in order to account for the nonlocal effects in the structure. These methods are especially appealing for simulations of realistic nanostructures modeled with SIE 128.

Nano-photonic systems incorporate a variety of materials with a range of geometrical features, including metals, subwavelength structures, and anisotropic materials. They can also incorporate a variety of geometrical features, such as holey fibers and quantum dots. Moreover, they can integrate many materials and processes at a single chip, making it a versatile tool for synthesis.

Topological Photonics

The development of advanced optical systems has many technological challenges. Traditional optical systems focus on geometric parameters that correlate to specific functionalities, such as single-mode operation or tight bending radius. This approach has several limitations, however, and the research community must take steps to overcome these limitations. Here are some of these challenges. Listed below are some suggestions to address them. In order to be effective in topological photonics applications, design optimization and large-scale fabrication of topological photonic systems are crucial.

Research in topological photonics is well-established, but many practical applications have been optimized using traditional techniques. To develop real-world applications, researchers must develop topological photonics beyond the limitations of traditional techniques. In the meantime, they must address these limitations and create new technologies that have multiple practical applications. To do this, researchers should explore novel concepts and investigate possible use cases, while evaluating existing technologies. If promising conclusions emerge, they can then be tested with proof-of-concept experiments in the lab and in collaboration with industry partners and startup companies.

Topological photonics is also a potential solution for shorter wavelengths. Achieving this goal would significantly increase the packing density of optical devices and allow for disruptive optical designs. This will lead to new applications for topological photonics. If the goals of the research community are met, this approach may be widely adopted. In the meantime, advancing the technology's performance and compatibility with existing manufacturing solutions can make it a viable option for manufacturing semiconductors.

Despite the progress in topological photonics, the field is still considered a difficult topic for many researchers. Its origins in condensed matter physics have prevented researchers from making topological photonics accessible to scientists from different disciplines. It is critical for researchers to communicate the potential benefits and limitations of topological photonics with other communities. With the widespread availability of silicon photonic foundries, researchers can produce new topological photonic structures rapidly.

What are Some Benefits of Silicon Nanophotonics?

Silicon nanophotonics technology provides answers to the challenges of big data, by seamlessly connecting different parts of a larger system, be they separated by just centimeters or kilometers, and moving terabytes of data through light pulses across an optical fiber. IBMs Silicon nanophotonics technology is able to integrate optical and electrical circuits side-by-side on a single chip. In addition, IBMs CMOS Nanophotonics technology is able to deliver multiple concurrent streams of optical data onto a single fiber, using on-chip, compact wavelength-division multiplexing devices.

Important Terms for Semiconductors and Nanophotonics

- nanophotonics technology

- nanophotonic chip

- nanophotonic interactions

- nanophotonic devices

- semiconductor fabrication

- photonic mode

- silicon nanophotonics

- optical detectors

- optical detection

- chip fabrication

- light detection

- semiconductor technology

- medical nanotechnology

- semiconductor insulators

- ir semiconductor

What Happened to The United States Lead in Semiconductor Chip Manufacturing?

Blame the 41st president of the United States George H.W. Bush! Ronald Reagan’s administration subsidized the United States Semiconductor Industry during the 80s. But the joke was that if you added all the profits and losses generated by the semiconductor industry that the losses would be deep in the red! True, but semiconductor technology, albeit from now-bankrupt companies, paved the way for all the cool tech and devices that we use today. Why did this happen? President Bush infamously made a fool of himself and perhaps helped cost him his 2nd term as president when he was clueless about how a grocery store he was visiting scanner worked. It showed how out of touch he was with the economy which was suffering a sharp recession.

Potato Chips, Computer Chips, What’s the Difference?!

People in Silicon Valley were outraged when Michael Boskin, a former Stanford University economist and chairman of the White House Council of Economic Advisers, reportedly stated that there was no economic distinction between potato chips and computer chips. This guy didn't know anything about technology.

High-tech executives from Hewlett-Packard Co. to Intel Corp. were delighted when Bill Clinton was elected. Laura D'Andrea Tyson (University of California at Berkeley) was chosen to succeed Boskin. Finally, an economist understood that silicon was more important than snacks for the nation's future economic success. Finally, an administration valued DRAMs far more than Doritos.

Wait a moment. Computer chips may be more sophisticated and intelligent than potato chips, but they are also byproducts of high-tech processes.

In the early 90s, many of the same problems that computer chip makers face are faced by potato chip manufacturers. Both operate in capital-intensive markets, which require large ongoing investments in research and new technologies. Both are in price wars in multibillion-dollar markets that are growing in size. The global potato chip market is worth $8 billion per year ($13 billion if you include corn chips). Both face challenges in finding profitable niches that they can avoid being commoditized.

Intel, in the early 90s, was and still is the largest manufacturer of computer chips in America. In the early 90s, it was about the same size as PepsiCo’s Frito-Lay Inc., which is the largest potato chip manufacturer with annual revenue of almost $6 billion.

But, potato chip makers are subject to a multitude of labeling and health regulations from the government that silicon chip manufacturers can ignore.

Gary L. Laabs is a vice president at Utz Quality Foods Inc. a privately owned potato chip producer.

The technology starts with the potato: Utz and Frito-Lay collaborate with university horticulturists in order to create potatoes specifically designed for "chipping." Chipping potatoes are designed to be round and not oval.

Laabs says that the potato's chemical composition is crucial if they are to chip well. "So, we test them constantly for moisture and sugar. Discussions are ongoing about genetically reengineering potatoes to improve their content and shape. This is high-tech technology no matter how you slice it.

The potatoes are then moved through a water flue to a huge peeler. Laabs says that these peelers work within extremely tight time limits and have very precise peeling tolerances. "So we don't end taking the potato's meat," he adds. Different types of potatoes require different settings because they have different textures.

After peeling the potatoes, they are visually inspected before being moved into the slicers. These have surgical steel blades that are set in a large brass drum. To minimize the possibility of breakage, the slices are carefully washed. The peel is used to make animal feed. Excess starch from potatoes is then turned into a slurry and sold to paper manufacturers companies.

The slices are then air-dried, and the oil is added to a large vat. The fryers at Utz are controlled by Allen-Bradley computer controllers. The majority of capital equipment, including the fryers, peelers, and other equipment that is used in potato chip manufacturing, is made in the United States. A potato chip line can be expensive to put together if you add it all up.

After they come out of the fryer the chips are seasoned or salted and then transferred to the packaging line. The chips are transported using vibrating conveyors, which jiggle the chips onto the scales and into their packaging. Laabs states that this is the most common way to move chips in the industry. It minimizes breakage."

Procter & Gamble Co.'s Pringles potato chips require a different manufacturing process that is even more technologically advanced.

The delivery of potato chips has been a great example of the logistical capabilities of computing and telecommunications. It is the envy of many Silicon Valley high-tech firms. Frito-Lay is now able to manage customer deliveries and inventory through technology, rivaling Federal Express Corp.

Although it is true that you don’t need a multibillion-dollar global consortium with Europeans and Japanese to create the next generation potato chip, one could argue that the continued consolidation of the semiconductor industry doesn’t bode well for future employment.

It is important to remember that the line between high-tech and low-tech industries has become increasingly blurred. It's not hard for a president or economist to question the vitality of the new semiconductor industry of the early 90s. However, it's just as easy to ignore the technological and market needs of the industry as mundane as potato chips.

If a nation is to be successful globally, it must recognize the potential and performance of both industries Semiconductor leadership means low tech biz can compete effictively by incorporating high-tech semiconductors into every aspect of their business.

Why Don't Car Manufacturers Make Their Own Semiconductors?

The automotive industry is a complicated one. There are tens of thousands of parts and layers of suppliers. The problem is that automakers have difficulty tracking each component's provenance. Big companies are favored over smaller ones by the auto industry, which means that smaller suppliers have trouble competing with them on price. This is why the industry depends on a few major suppliers for high-pressure fuel lines and specialized plastics.

![]()

Global semiconductor

With the global demand for automotive-grade semiconductors increasing, the auto industry will need to rethink the current way they source this critical component for their products. With up-front volume commitments from OEMs becoming more binding, the industry can shift the current 12 months of supply time to six months and move to the production level. This would provide a more balanced risk-sharing plan for all parties involved, which would encourage adoption rates.

In 2015, the Asia-Oceania region accounted for the largest share of the automotive semiconductor market. The region's automotive industry has become a global hub, and it accounts for the vast majority of the semiconductor market in terms of sales and production. As a result, China is the largest consumer of automotive semiconductors, while North America is the fastest growing region. These factors will likely continue to increase the demand for automotive semiconductors through 2023.

Although the auto industry's demand for semiconductors decreased in the first half of 2020, new-vehicle sales have recovered. However, the auto industry faced a severe shortage of these components in early 2020. While the market recovery continued, it was not enough for automakers to increase their orders for semiconductors. On the other hand, the demand for personal computers, wired communications equipment, and servers rose. While semiconductor shortages may be temporary, they can affect a wide range of industries.

While global auto sales have increased steadily over the past decade, the shortage of semiconductors is still a significant issue, and is expected to continue into 2021 and beyond. The car market will be affected by this shortage of chips for 22-plate cars. It will be an enormous problem for the industry and for consumers. The shortage of semiconductors could affect the production of conventional cars by 2021. The chip shortage, however, will affect both carmakers and consumers.

With the global chip shortage continuing, carmakers will face production delays, temporary shutdowns, and even a lower quality of cars. In the meantime, some automakers have halted production and suspended some optional features. For instance, General Motors has built some models without seat heat or ventilation. However, these can be added retroactively. These are all measures that can help carmakers improve their supply chain. So, now is the time to make some changes in the supply chain.

Legacy auto industry Semiconductors

The legacy auto industry is not alone in making its own semiconductors. While it represents a small percentage of the chip industry, the automaker is struggling to get the chips it needs to keep up with demand. The global supply of these chips is predicted to catch up only in 2025. As a result, automakers are relying on suppliers to supply the computing hardware needed to run their vehicles. The suppliers in turn deal with chip makers, and the supply of legacy chips will be affected by the new demand.

Several decades ago, the auto industry was too conservative about the future of technology. It relied on archaic technologies that are not applicable in other fields of consumer tech. This reluctance to change is finally coming to an end. The only fools would invest in shops that pump out outdated silicon. This trend is starting to reverse itself, however, and the automotive industry should embrace this change. However, the challenges are many.

The semiconductor shortage is affecting manufacturing around the world, and the automotive industry is no exception. It has slowed production and forced the temporary closure of assembly lines. In fact, according to AutoForecast Solutions, North American automakers will lose 2.3 million vehicles by 2021 because of plant shutdowns. The impact of this shortage has reached the level of Congress, where several members are considering legislation to help boost domestic production of semiconductors.

The shortage of these chips is impacting the entire automotive supply chain. Despite a significant shortage, many plants have frozen production. A recent report from Peugeot's executive board said that the company would be reducing the digital speedometer on its Peugeot 308, to save chips for more popular models. Further, the shortage of these chips could lead to the production of many other auto parts, including the next generation of electric and hybrid vehicles.

While the automotive industry is heavily dependent on mature semiconductors, the industry is also transitioning to new electronic architectures. With the development of autonomous driving and electrification, the automotive industry is focusing on software-based features and electronics. As the industry transitions to these new electronic architectures, it will need to increase the amount of power electronics in its vehicles. This means that the automotive semiconductor market will continue to grow and increase.

What is the Impact of chip shortage on new-car sales?

The recent chip shortage has had a significant impact on the new-car market, leading automakers to slash production of new vehicles. This is affecting the industry's metric known as "days supply," which indicates how much inventory an automaker has relative to demand. As a result, the days supply of new-car inventory is rapidly diminishing, which means that automakers are less likely to negotiate and discount their inventory.

A chip shortage has been affecting the auto industry for over a year, forcing many manufacturers to cut back on production. Since the chip shortage began in 2020, automakers faced a steep decline in new-car sales. At the same time, demand for other electronic devices rose sharply. When the auto factories resumed production at the end of 2020, chipmakers were unable to keep up with the demand. The shortage is expected to continue for at least six months, but in the longer term, the situation will continue for many years.

As a result of the chip shortage, automakers will have to cancel orders and sell incomplete vehicles. The affected vehicles will need to be installed by a dealer. Globally, almost 1.2 million new vehicles will not be sold this year. Those cuts will make it hard for automakers to make up for lost revenue and production. New-car prices are already higher than last year, and this doesn't even include factory rebate deals.

Last week, automakers canceled production schedules for 87,500 vehicles, and four thousand from European factories. These cuts will continue into the months ahead, and will impact new-car inventories. Analysts have held out hope that the chip shortage will end in 2022, but it may continue into the following year, which is a full year after that. But it's not looking good for automakers and consumers.

The auto industry has seen significant disruptions in the last few months due to the chip shortage. It's been a challenging time for the industry, affecting production, inventories, and prices. As a result, some carmakers have scaled back production and switched production from expensive cars to cheaper, cash-generating vehicles. While the auto industry has recovered from the 2020 plant closures, the chip shortage has forced automakers to delay production until they have more chips.

What Efforts Would Ensure Continuous Supply of Chips?

Efforts to ensure the continued supply of chips for cars are underway as automakers scramble to ensure they have enough supplies for production. Since semiconductors have long lead times, the current shortage is further down the supply chain. While automakers partially build their products and store them until chips are available, they may consider direct purchasing of parts from smaller suppliers. That would cut out most of the supply chain. According to IHS Markit, the current shortage in chips will result in the production of 672,000 fewer vehicles in the first quarter of 2021. In the case of the U.S. alone, that could mean a 250,000 decrease in the number of cars produced in the largest vehicle market in the world.

Currently, the auto industry represents just five percent of the chip industry. As such, most automakers are planning a pause in production during this period to allow for the shortage to be alleviated. But if the shortage continues for a longer period of time, automakers are likely to run out of chips before the next peak in demand. If this happens, the chip shortage could lead to a shortage in consumer electronics as well as knife fights.

While carmakers may not see the shortage in cars until 2020, the biden administration's new initiative aims to address this problem by increasing domestic production and partnering with international partners to stabilize the chip supply chain. The administration has announced plans to launch a 100-day review, which is expected to include sectoral reviews of supply chains. But in the meantime, these steps might not be enough. In the meantime, chip makers are expanding their production facilities in Asia.

Although a shortage in automotive chip manufacturing has been a problem for many years, there are positive signs for carmakers. Some automotive OEMs have lowered their forecasts because of the lack of supplies. As a result, chip makers have increased production for consumer goods, while their automotive customers decreased their orders. Several tier one and two suppliers have redirected their capacity to higher-margin customers.

Video: Chip Shortage and The Automobile Industry

Understanding Failure Analysis in Semiconductor Synthesis and Defect Science

Materials scientists have been studying semiconductor defects for many years. Their studies have shown that the volume of semiconductor defects depends on the defect's charge. When electrons are added or removed from the defect site, volume changes are positive or negative. Scientists have developed three basic rules to describe semiconductor defects:

Materials Science Discovery

In addition to chemistry and material science, computational methods and data science are essential for the development of novel materials. Such methods include device modeling, multiscale simulations, continuum modeling, and active machine learning. Courses in materials science discovery include MSE 441 and CHEM E 545, respectively. In addition, the course requires a hands-on approach to materials discovery using computational modeling. Materials scientists can use this knowledge to create better materials for various applications, including energy, healthcare, and the environment.

The high-throughput approach to materials discovery has several advantages. It improves the probability of discovering new materials with useful properties while reducing the time and human effort required to investigate the composition space. Moreover, it is suitable for materials discovery when there is a well-defined problem to solve. The cost is also reduced, and a new material is available at a lower price. But this approach is not applicable for unexplored composition space.

The fundamental building blocks of materials science are the chemical elements. Elements have atomic weights and are defined by the number of protons in their nuclei. The heavier the element, the higher its atomic weight. Scientists can synthesize heavier elements in nuclear laboratories, but they are radioactive and decay rapidly. So far, 24 synthetic elements have been made, up to element 118 with 294 protons.

Other applications of materials science include the study of metals and their alloys. Metals account for the largest portion of metallic alloys in use today, and iron alloys make up the most common. Among these are steel, stainless steel, cast iron, tool steel, and alloy steel. However, the most important applications of materials science are in space exploration, where various components must withstand harsh environments and extreme temperatures.

What is Semiconductor Device Modeling?

The field of device modeling in semiconductor synthesis and defect science has recently emerged as a promising research topic. As a part of this research, a multi-scale modeling approach has been developed, beginning with an atomistic model for studying the fundamental electronic properties and charge transfer. The compact device model is then developed based on energy band structure to evaluate transistor characteristics. Various models are then implemented in a circuit simulator to facilitate the design and synthesis of integrated circuits. The proposed modeling framework allows the translation of phenomena observed at the atomic level to circuit performance metrics.

Nanomaterials, which are nanoscale structures with a size of one to 100 nm, are another promising research topic. Nanomaterials are able to exhibit different properties from bulk materials, and their size can be controlled and tuned to produce specific characteristics. Nanomaterials can be used for a wide variety of applications, from energy conversion to storage. Device modeling is a key area of expertise at the University of Texas at Austin. Professor Sanjay Banerjee's work is a great example of this.

Device modeling in semiconductor synthesis and defect science can help the semiconductor industry evaluate emerging 2D materials, including all-2D MISFETs. These new materials are difficult to integrate into existing devices, and a first principles-based model is useful to evaluate their performance in a systematic manner. One example is the all-2D MISFET, which consists of a hexagonal boronide-like semiconductor.

Whare is Substitutional Point Defects in Semiconductors?

There are a number of fundamental properties that govern the behavior of substitutional point defects in semiconductors. These defects are thermodynamically favored to occur at finite concentrations and temperatures, and are more mobile than perfectly bonded atoms. The formation energy of these defects strongly influences the concentrations they can form. The formation energy is an important material property because it determines the diffusion rate of atoms. It also has implications for oxidation.

In semiconductors, substitutional point defects introduce electronic levels into the bandgap. The donor level becomes positively charged when the electron is given up, while the acceptor level becomes negatively charged when it occupies the electron. In the case of Ga2O3, for example, the donors compensate for the Mg acceptors. In semiconductors, shallow and deep levels are classified according to their location in the bandgap, and deep levels are farther from the extreme band regions.

The formation energy of SIAs is higher than that of vacancies. Consequently, SIAs are rarer than vacancies, but they are abundant in irradiated metals. Hundreds of SIA-vacancy pairs can form in a volume of 10 nm, following a displacement cascade mechanism. Point defects have a definite effect on the material properties, and the intracascade fate of the defect determines how many are formed.

Substitutional defects are caused by the addition of an atom that is not present in the crystal structure. This foreign atom can distort the crystal's lattice structure. As a result, it can alter the thermal and mechanical properties of the solid. The presence of a foreign atom may also cause substitutional defects in semiconductors. They are found in brass and steel. Sometimes, these defects are caused by natural impurities or intentional addition during the conversion of iron to steel.

Growth of colloidal nanocrystals

Growing colloidal nanocrystals in solution can be a useful tool for improving the electrical and optical properties of semiconductors. This new technique is also a valuable resource for solid state lighting and biological imaging. The project will include educational aspects, including curriculum development and research activities. Researchers from around the world are exploring the possibilities of colloidal nanocrystals to enhance semiconductor devices.

The growth of colloidal semiconductor nanocrystals involves a reaction-limited growth mechanism, similar to that of oil droplets coalescing in water. Surface tension of colloidal nanoparticles is reduced during the aggregation process, which can be controlled using the proper particle surfactants. The method is particularly useful in semiconductor synthesis and defect science, where the fusion of dissimilar nanoparticles leads to highly uniform nanostructures.

This technology is being used to synthesize a variety of shapes for semiconductor nanocrystals. The growth of CdSe nanoparticles is one such example. The two-component CdS nanoparticle dimer has a highly desirable shape and is suited for catalytic applications. Moreover, the dimer is ideal for semiconductor catalysis, as it enables simultaneous oxidative and reductive reactions on dissimilar nanoparticle surfaces.

The growth of colloidal nanocrystals is a major research focus in semiconductor synthesis and defect science. The goal of this research is to develop colloidal quantum dots (QDs).

Failure Analysis

The importance of failure analysis in semiconductor synthesis and defect science is evident in the increasing complexity of modern devices. As devices become more complex, the defects that lead to the failure may be concealed by high-density interconnects, wafer-level stacking, flexible electronics, and integral substrates. Defects that affect yield and reliability at this stage can have disastrous effects on the overall product. With the advent of advanced analytical techniques, it is possible to detect and characterize electrical defects, significantly reducing the time and cost of electrical fault isolation.

This course also examines the mechanisms underlying failures and their causes. Students will gain a better understanding of the underlying mechanisms of failure, as well as the tools and techniques used to investigate and predict them. The course also focuses on materials for structural applications, as well as the basic principles of dislocations and plasticity. This course requires graduate standing and permission of the instructor. The course is not open to non-majors.

Video: Defect Tolerances in Semiconductors

How Can a New Type of Transistor Change the World of Electronics?

When it comes to transistors, you probably know that they can detect radio signals. But what about ![]() bipolar junction transistors? And how about field effect transistors? Read on to find out more about these important electronic components. During the last decade, transistors have been making waves in the electronics industry. Here are some ways they're changing the world of electronics. So how does a new type of transistor work?

bipolar junction transistors? And how about field effect transistors? Read on to find out more about these important electronic components. During the last decade, transistors have been making waves in the electronics industry. Here are some ways they're changing the world of electronics. So how does a new type of transistor work?

Bipolar junction transistor

Researchers at MIT and Harvard University have discovered that a device called the bipolar junction transistor (BJT) is capable of changing the state of matter in a semiconductor. The research may open a number of applications in a variety of fields, from synchrotron light to medical diagnosis. It may even be used to monitor radiation dose in patients and workers. If this research is successful, it could create new technologies for information technology, such as digital memory cells.

A bipolar junction transistor is a three-terminal semiconductor device that combines two types of semiconductor material. It is typically made of silicon, but some impurities, such as metal, are added by doping to make the layers behave in the way that they do. The p-type layer attracts electrons from the input circuit while the n-type layer encourages electrons to flow out. A push-and-pull effect is the result. As a result, electrical current is amplified.

A BJT consists of a thin slice of a p-type semiconductor and two pieces of an n-type semiconductor. A BJT is also called a bipolar junction transistor (BJT). Depending on the material used, a bipolar transistor is either NPN or PNP. NPN means that the majority of the charge carriers are in one part of the transistor. The N-type transistor is the most common type. Its high mobility means that it can operate at higher currents and speeds than the P-type transistor.

The electrical resistance between the emitter and collector can vary greatly. The higher the VBE, the higher the emitter current. A typical silicon BJT has a VBE of 0.3 to 0.8 mV. In contrast, the VBE of 0.8 V increases current intensity by a factor of ten. The resulting effect is a transistor that can change the world of electronics. When the transistor is in the active state, it amplifies base current.

Field effect transistor

In addition to its many applications in electronic circuits, the Field Effect Transistor is also a very versatile component of modern electronics. In many applications, the transistor is used for the production of small and low-power electrical devices. Its versatility has led to numerous improvements and advances in electronics. A transistor's operating current is directly proportional to the voltage it receives from the gate. Generally, a field-effect transistor operates at a constant gate voltage. A transistor with a constant gate voltage, for example, is referred to as an enhancement field-effect device.

To demonstrate how the Field Effect Transistor works, first determine its working point. Then, make sure that it is a metal-oxide semiconductor. Its working point can vary depending on the type of device, but the most common are MOS-FETs, which are made from metal oxide semiconductor. Fairchild Semiconductor, Bell Labs, and hundreds of other Silicon Valley companies have been developing this device.

To create a Field Effect Transistor, you need a multimeter with a resistance setting of Rx1k. Connect two test leads to the transistor's gate, the source, and the drain. The resistance of these two pins should be similar to each other. If the two resistances are similar, then the two pins are the source and the drain, while the remaining one is the gate.

There are several types of characteristic curves in a Field Effect Transistor. There are four types of transfer characteristic curves, and four types of output characteristic curves. The difference between these two types of circuits lies in the voltage and current directions. It is important to note that a FET has more amplification capacity than a transistor. However, the FET is more difficult to produce than a transistor.

Point contact transistor

A point contact transistor can change the world of electronics. This device is based on the principle of electron mobility in a semiconductor crystal. It was developed by scientists John Bardeen and Walter Brattain at Bell Laboratories in 1948. They worked in a team of solid state physicists under the direction of William Shockley. The researchers were working on theories of electric field effects in solid state materials and wanted to replace the vacuum tubes with a more compact device.

A point contact transistor has a common base current gain, while bipolar junction transistors cannot. Unlike bipolar junction transistors, point contact transistors operate at lower frequencies. Their failure rate was relatively high, meaning that many commercial encapsulated transistors had to be discarded. Point contact transistors have higher cutoff collector current and are more resistant to moisture attacks. This makes them an excellent choice for use in communications equipment, especially in cellular telephones.

A point contact transistor can change the world of electronics and save lives. It has been called the miracle transistor. The invention was made possible because of the discovery of Germanium. In the 1940s, Germanium was less expensive and easier to work with, so Brattain isolated it from the metal by applying an oxide film. However, many tests failed to produce good amplification. But one day, Brattain accidentally removed the oxide layer and made gold contact with the germanium.

Initially, the term "transistor" referred to only one type, the point contact transistor. This type was soon replaced by the bipolar junction transistor. However, efforts to introduce more accurate versions of the transistor failed. Nowadays, the term "transistor" refers to all types of transistors, which include bipolar junctions, field effect transistors, and RF/AV devices. They are made up of two types of electrical charges - the base and the collector.

Detecting radio signals by a transistor

Detecting radio signals by a new kind of transistor in electronics has a long history, and is still relevant today. The first operational transistor was declared on December 23, 1947, and led to the development of integrated circuits, microprocessors, and computer memory. The transistor, also known as a bipolar junction transistor (BJT), is a current-driven semiconductor device that can act as a switch and amplify weak signals. Its basic structure is comprised of a silicon crystal sandwiched between P-type and N-type layers.

To detect radio signals, the circuit should contain a large capacitor to store the peak RF waveform. The capacitor should be large enough to prevent the output signal from attenuating the modulation. The source impedance of the circuit should be high enough to prevent the transistor from landing too far in the RF band. Silicon devices work well with reversed battery polarity. Ideally, a single transistor in the circuit is tuned to the carrier frequency.

SETs can be used as highly sensitive charge detectors. SETs can measure very small mechanical oscillations as well. Piezoelectric materials are an important approach to realizing mechanical resonators. The 6-mm-disk resonator can reach a resonance frequency of nine MHz. The new device could be used to detect radio signals. This breakthrough is a big step forward in electronics research.

Using a novel type of transistor in electronics can be a powerful way to detect radio signals. Using an exclusive-OR logic gate, it can detect a limited FM signal and a copy of the signal passed through an LC circuit and a fixed-frequency square wave carrier. A stream of output pulses corresponding to a varying frequency of the two signals can be generated. This resulting pulse-width modulation signal is the result.

Evolution of transistors

In the late 1940s, William Shockley and Henry Ford were working on a new type of semiconductor device called the transistor. These devices are comprised of two layers of semiconductor material - an outer layer of N-type germanium and an inner layer of P-type germanium. A small voltage is applied to the outer layer, which allows a current to flow. However, a weak voltage applied to the middle layer will disrupt the flow of electrons.

The first commercial uses of transistors were in pocket radios and hearing aids. Radio signals are weak and need to be amplified to produce audible sounds. Transistors replaced vacuum tubes in radio signals and oscillator circuits after specialized structures evolved that could handle higher frequencies. Today, most transistors are made of silicon or metal-oxide semiconductors. As more electronic devices become integrated circuits, the use of transistors has increased dramatically.

The emergence of transistors changed the way computers work. As computers became more sophisticated, engineers began to search for simpler ways to design transistors with greater performance. These new devices made it possible to design computer chips with billions of microscopic transistors. However, the transistor era may soon be coming to an end. DNA-based circuits and transistors made of atoms may be the next generation of semiconductor technology.

While scientists began to understand the physics behind transistors during the 1940s, they had a difficult time manufacturing them. The first transistor, known as a point-contact device, was used in the Bell telephone system. But the transistor itself was difficult to manufacture and control. Eventually, Brattain and Ford succeeded in developing a three-terminal solid-state device. That transistor was called the Type-A transistor.

Understanding a Semiconductor

You might have heard of the term semiconductor before but are unsure about its meaning. This article will discuss its properties, functions and the common elemental semiconductors. The first step in understanding a semiconductor is to learn about its properties. These include its electrical conductivity. To understand how semiconductors work, consider their three states: valence band, p-type and semiconductor. Each type of semiconductor has a unique p-type, which indicates the degree of electronic conductivity it has.

What is a Semiconductor's Electrical Conductivity

The electrical conductivity of semiconductors increases as temperature increases. The reason for this is because electrons can jump from their valence band into the conduction band when energy is applied. This property makes semiconductors ideal for use in electronic devices. Although semiconductors are usually poor conductors, as the temperature rises, their electrical conductivity improves exponentially. The reason for this property is due to a difference in charge carrier density in the two bands.

A semiconductor is a material that possesses electrical conductivity in a region between conductors and insulators. It is classified as either pure or compound and can be either electrically or thermally conductive. Both types of semiconductors exhibit a high degree of electrical conductivity and are used in many applications. In this article, we'll discuss how a semiconductor works and what makes it useful for electronic devices. A semiconductor's electrical conductivity is defined as its capacity to transfer electricity between two different materials.

The electrical conductivity of a material is determined by its concentration of free electrons. High-conductors have a high concentration of free electrons and low-conductance materials have a relatively small concentration. Semiconductors are in between these two extremes, with a concentration level between conductors and insulators. The high conductivity of a semiconductor is important for electrical devices. Having high electrical conductivity increases the efficiency of electronics, while low-conductors decrease the efficiency of electronic devices.

What are Semiconductor Properties?

A semiconductor is a material with properties similar to conductors, such as resistance. The resistance of a semiconductor decreases with increasing temperature, and its conductivity increases with addition of impurities. The process of doping a semiconductor, which adds impurities to the material, increases its electrical conductivity. At a low temperature, a semiconductor is an insulator, but when heated, it becomes a conductor.

A semiconductor has two distinct energy bands, or "bands" - the valence band and the conduction band. The gap between these two bands is known as the energy gap. The width of the band represents the density of available states. In semimetals, the Fermi level is inside one of these bands. In semiconductors, the gap is near the Fermi level, which makes them excellent candidates for electronic devices. This is one of the most important properties of a semiconductor.

All semiconductors are made up of four electrons in their outermost orbit. These electrons form perfect covalent bonds with four other atoms. In some cases, they form crystals. The crystals formed by carbon and silicon semiconductor materials may resemble diamonds or a silvery metallic substance. These crystals are formed because of a process called doping. It's crucial to know how to do this properly. To do it properly, it's necessary to understand the nature of semiconductors and how they work.

What are Semiconductor Functions?

Semiconductors are crystals with two types of atoms, holes and electrons. Both are present in the same material, and when an electric field is applied to the material, holes and electrons move through the crystal and participate in the current conduction. The electrical conductivity of a material is determined by its number of charge carriers per unit volume, and their mobility in an electric field. Intrinsic semiconductors have equal numbers of holes and electrons, but different velocities and mobilities in an electric field.

The success of the semiconductor industry is highly cyclical and undergoes boom and bust cycles. Demand for semiconductors typically tracks end-market demand for electronic equipment. If PC sales are slow, then semiconductor companies may be unable to produce enough microchips to meet consumer demand. This, in turn, can cause the industry to experience a major slump. The semiconductor industry may be hit by a wave of bad luck and a crash in the stock market.

Semiconductors are crystalline solids that are intermediate between an insulator and a conductor. They are used in electronic devices to control current flow, and are capable of integrating into complex microelectronic circuits. This article will focus on the functions of a semiconductor, and provide an overview of its various uses. This article covers some of the most common types. So, what are they and how can they benefit you?

What are Common Elemental Semiconductors?

Semiconductors are substances with properties that fall somewhere in between the insulators and metals. They are the building blocks for electronic discrete components. Silicon, germanium, gallium arsenide, and indium antimonide are common elemental semiconductors. Silicon is the most common semiconductor, and is used in most modern integrated circuits. These compounds also have unique properties, but are not widely used in electronic applications.

Listed in Column IV of the periodic table are elements that make up semiconductors. These include silicon, germanium, gallium arsenide (GaAs), and zinc oxide (ZnO). All these elements are derived from chemical reactions between two or more elements. Various elements in this category are used in semiconductor devices. Some semiconductors are made of alloys of two or more elements, such as silicon and gallium indium telluride (HgIn2Te4).

Semiconductors are a group of elements with a high stoichiometry, and they can be n-type or p-type. Silicon is the most common elemental semiconductor, and is found in glass, sand, and in the atomic structure of DNA. The next most common elemental semiconductor is germanium, which is the element directly below silicon on the periodic table. These two materials are used in electronic semiconductors and in computer circuits, and are considered semimetals.

Some metalloids are semiconductors as well, such as boron. In addition to silicon, pentavalent impurities such as phosphorus contribute a free electron to a semiconductor. Trivalent impurities, on the other hand, create holes in the intrinsic semiconductor. So if you're looking for a new elemental semiconductor, you should take a look at the following table. These elements are both essential for electronic devices.

What are Extrinsic Semiconductors?

The term "extrinsic semiconductor" refers to a type of semiconductor that has undergone doping. The doping agent may be a trace element or a chemical. In order to increase the conductivity of the semiconductor, it must contain a high amount of a trace element or chemical. The amount of doping will depend on the semiconductor's size, and will be a key factor in the device's performance.

Extrinsic semiconductors are divided into two categories, N-type and P-type, according to the type of impurity that has been added to them during the crystal-growing process. Pure semiconductors consist of silicon, germanium, and gallium, which are tetravalent elements. They are classified as either N-type or P-type based on the type of impurity added to the crystals.

The impurity is added to the 108 atoms in a semiconductor crystal. This increases the number of free electrons and holes. A pentavalent impurity has five valence electrons, while a trivalent one contains three. The additional charge carriers are equal to the ionised cores in the lattice. Pentavalent impurities are also used in the manufacturing process.

The energy level of the acceptor is higher than that of the valence band. This allows electrons to move from their valence band to level Ea with minimal energy. Even at room temperature, Extrinsic semiconductors conduct. In contrast, the former type does not require any impurities to conduct electricity. And despite its low conductivity, this is one of the main reasons why they are called n-type semiconductors.

What are P-type Semiconductors?

In electronics, a semiconductor is a material in which the electrons are more numerous than the holes. A p-type semiconductor allows current to flow from hole to hole in one direction, but not the other. These materials are made with different materials to achieve different electrical properties. This article explains the differences between p-type and n-type semiconductors. The main difference between the two types of semiconductors is their conductivity.

A p-type semiconductor is formed by doping with an impurity from the III or V groups. It creates a hole that is the acceptor of electrons. A hole in a p-type semiconductor will move from a lower potential to a higher one. In n-type semiconductors, an impurity is added to create an extra electron or hole. The difference between these types of semiconductors is that a semiconductor made with a p-type semiconductor is more difficult to make than an n-type semiconductor.

A semiconductor with an acceptor atom is known as a P-type extrinsic semiconductor. It is characterized by a higher concentration of holes compared to electrons. The positive charge on these materials is attributed to the presence of holes. The electrons, on the other hand, are the minority carriers. This explains the naming of a p-type semiconductor. So, what are the benefits of a P-type semiconductor?

What are Commonly used Material in the Manufacturing of Semiconductors

This article discusses the advantages and common materials used in Semiconductor manufacturing.

Silicon and its derivatives are the most common materials used to produce semiconductors. Silicon is the second most abundant element on earth and makes up more than 25% of the earth's crust. The metal silicon is produced by the reaction of silicon dioxide and carbon materials such as wood chips. Suppliers of silicon wafers can be found throughout the world. However, China is reportedly the largest producer. So, how do they make semiconductors?

Silicon (Si)

Silicon is an abundant material found in the earth's crust. It can be easily refined to make high-quality semiconductors. Its availability also makes it more affordable for the consumer. In addition to being a cheap raw material, silicon is also environmental-friendly. The following are the advantages of silicon in the manufacturing of semiconductors. Let's look at each of these in more detail. Here's a quick guide to silicon.

The most commonly used semiconductor materials are crystalline inorganic solids, which are grouped by position in the periodic table. Their properties depend on the number of electrons they possess in the outermost shell. Other types of semiconductor materials include gallium arsenide and indium, which are used in the manufacture of photodetectors, LED lights, and lasers. Other elements of group IIA-VIA are also used in electronics, such as mercury and cadmium.

Copper (Cu)

In the semiconductor industry, copper is a highly versatile material. This is because of its excellent conductivity. The metal was initially considered too expensive for use as metal lines in integrated circuits, so aluminum was chosen. Recent technological advances have made copper an ideal choice for this role. Here are some of its common uses. Listed below are just a few of them:

For electronic applications, copper is used for radio frequency identification (RFID). This technology is a popular way to track and pay for items, like at gas stations. Copper increases the range of RFID. It's also used to make printed circuit boards. This is accomplished by laminating copper on a flexible film and then etching it so that it forms thin solid lines. The inkjet process also eliminates waste and makes the circuits cheaper to manufacture.

Aluminum (Al)

The use of aluminum in semiconductor fabrication has many benefits. For example, Aluminum is an excellent conductor of heat and electricity. Additionally, it can be easily structured with dry etching processes. Finally, aluminum is cheap and can be found in a wide variety of forms, including ingots, wafers, and wafer-level assemblies. This makes aluminum a popular choice in the semiconductor industry. The following are a few examples of uses for aluminum in semiconductor manufacturing.

The use of aluminum in semiconductor manufacturing has limited its application to the manufacturing of microprocessors, as this material is susceptible to corrosion. To counteract this, copper wires are an excellent choice. These wires are flexible and can be used for semiconductor manufacturing. Copper wires are also far more reliable than aluminum, which means they can be shrunk much smaller without sacrificing performance. Copper wires are able to conduct electricity with 40 percent less resistance than aluminum, resulting in a 15 percent burst in microprocessor speed.

Gallium Arsenide (GaAs)