Sapphire for Coplanar Waveguides

A PhD researcher requested the following quote:

I'm looking for sapphire substrates for coplanar waveguide purposes. Must be 1.5-2.0mm thick. Ideally 4" diameter.

Diameter: 100 +/-0.05 mm

Thickness: 1 +/-0.05 mm

Ori: C-plane +/-3deg

Surface quality: 1 side epi-polished

DSP epi-polished

Primary flat: 32.5 +/-1mm, A-plane+/-0.5 deg

Small protective chamfer

Reference #118232 for specs and quantity.

Get Your Quote FAST! Or, Buy Online and start researching today!

What are Coplanar Waveguides?

Coplanar waveguides (CPWs) are a type of electrical transmission line used for microwave frequency signals. They are particularly significant in the field of microwave engineering and integrated circuit design. Here's a detailed explanation:

-

Structure: A CPlanar waveguide typically consists of a central strip of metal (the "signal line") and two adjacent, parallel strips of metal (the "ground planes") on the same plane of a dielectric substrate. The central conductor and the ground planes are usually separated by a small gap.

-

Operation: The electromagnetic waves in CPWs are confined to the region around the central conductor. The design allows for signal transmission with low dispersion and low radiation loss. This is particularly important in high-frequency applications where maintaining signal integrity is crucial.

-

Applications: CPWs are widely used in microwave circuits, such as filters, amplifiers, and antennas. They are also employed in high-speed digital circuits and in applications where integration with planar technologies is beneficial. This includes applications in wireless communications, radar systems, and other microwave systems.

-

Advantages: The main advantages of CPWs include their planar structure, which makes them easy to fabricate and integrate with other circuit components. They also provide good isolation, minimal dispersion, and can support multiple modes of propagation, which is useful for certain types of microwave devices.

-

Design Flexibility: CPWs offer designers flexibility in impedance control and electromagnetic field confinement. Adjusting the width of the central conductor and the gap between it and the ground planes can control the characteristic impedance of the waveguide.

-

Challenges: One of the challenges in using CPWs is managing the mode conversion, especially at discontinuities and bends. There is also the potential for increased loss at higher frequencies due to surface roughness and the skin effect in the conductors.

Overall, coplanar waveguides play a significant role in high-frequency signal transmission and are a key component in modern microwave and RF engineering.

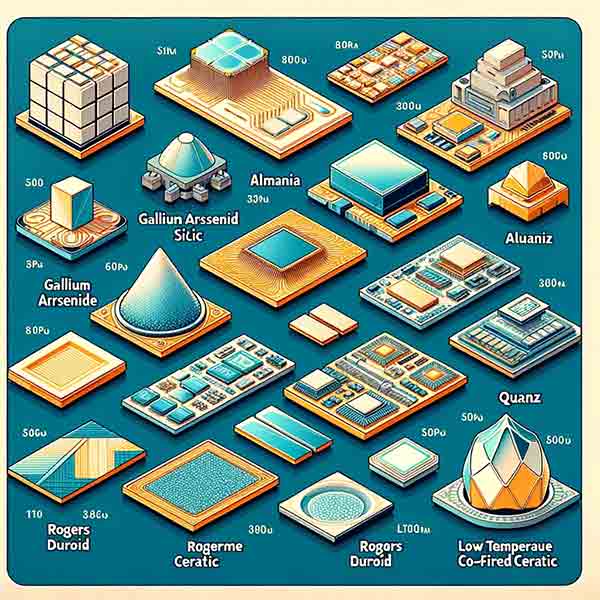

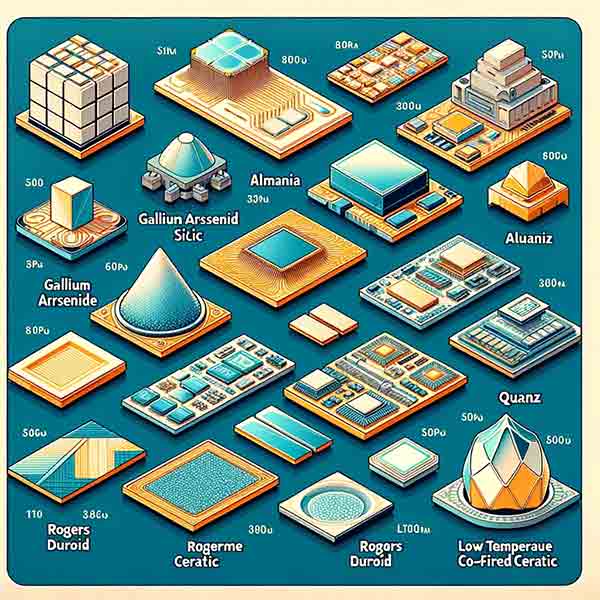

What Substrates are often used in Coplanar Waveguide Research?

In the context of coplanar waveguides (CPWs), various substrates are used based on the specific requirements of the application, such as the operating frequency range, power handling capability, and fabrication technology. Some commonly used substrates include:

-

Silicon (Si): Widely used in integrated circuit (IC) technology, silicon substrates are common in applications where CPWs are integrated with semiconductor devices. Silicon's high dielectric constant allows for a smaller wavelength at a given frequency, which can be advantageous for miniaturization.

-

Gallium Arsenide (GaAs): GaAs is often used in high-speed and high-frequency applications. It offers a higher electron mobility than silicon, making it suitable for very high-frequency applications, such as in radar and communication systems.

-

Alumina (Aluminum Oxide, Al2O3): Alumina is a popular ceramic material used in microwave applications due to its relatively high dielectric constant and good thermal conductivity. It is often used in applications where high power handling and stability are required.

-

Quartz: Known for its low loss and stable electrical properties across a wide frequency range, quartz substrates are used in precision applications where minimal signal attenuation and phase stability are critical.

-

Rogers Duroid and Other Teflon-Based Materials: These materials are used for their low dielectric losses at microwave frequencies. They are particularly useful in applications where performance at very high frequencies is a priority.

-

LTCC (Low Temperature Co-fired Ceramic): LTCC is a versatile substrate material used in multi-layered circuit designs. It is beneficial in complex microwave circuits and systems where integration of passive components is needed.

-

Flexible Substrates (like Polyimide): These are used in applications requiring flexibility, such as in wearable electronics and conformal antennas.

The choice of substrate depends on various factors, including the desired electrical properties, fabrication techniques, cost, and the specific application requirements. Each material offers a unique set of properties that can be leveraged to optimize the performance of coplanar waveguide-based devices and circuits.