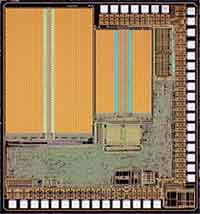

Fabricating Microchips With A Polysilicon Gate Structure

A physics student requested help with the following research project.

We would like to make microchips with a polysilicon gate  structure, and for what we know now we need a P-doped semiconductor wafer with <100> orientation, but if it couldn't be obtained we could change the process for another type of wafer, because we are in the early stages of the project.

structure, and for what we know now we need a P-doped semiconductor wafer with <100> orientation, but if it couldn't be obtained we could change the process for another type of wafer, because we are in the early stages of the project.

I'm looking to buy a P-Type 100 oriented silicon wafer with polysilicon deposited on top. On your website I can buy polysilicon wafers, but it doesn't tell me what the orientation or the dopation of the silicon is. Where could I find this information?

Reference #274460 for specs and pricing.

Why are Microchips Made from Silicon?

A semiconductor can conduct electricity or act as an insulal or Microchips are mostly fabricated from silicon because of its effective semi-conducting properties. Semiconductor microchips are ubiquitous in almost all electronic devices.

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

What Silicon Quality is the Most Important for Microchips?

Silicon wafers ubiquitous use as the primary semiconductor material in microchips has one problem, “waviness!” Microchip quality and yield depends on the silicon substrates surface quality. That quality is compromised during the wire sawing (cutting), lapping, etching and polishing of the silicon wafer. That waviness issue can be measured in BOW, WARP and Total Thickness Variation (TTV). The TTV measures the average difference between the high and low points of the polished silicon surface. The closer to 0 microns that you can get the better the BOW and WARP specs. But this is almost impossible. But a silicon wafer with a 1 micron TTV can be had. UniversityWafer, Inc. carries a large inventory of 1 micron, 2 micron, 5 micron TTV wafers in stock for all your microchip fabrication needs.

Engineers use silicon to build a circuits gates and switches. Silicon is not like copper or insulating as glass. It's in between. Silicon transistors use semiconductor wafers as on and off switches. Currently microchip have billions are transistors and growing. The switches in transisitors power electronic diveces, such as CPU, are currently the most efficient manner of calculating mathematical and logical processess.

Engineers use silicon to build a circuits gates and switches. Silicon is not like copper or insulating as glass. It's in between. Silicon transistors use semiconductor wafers as on and off switches. Currently microchip have billions are transistors and growing. The switches in transisitors power electronic diveces, such as CPU, are currently the most efficient manner of calculating mathematical and logical processess.

Silicon is used in CCDs because of it's semiconducting properties.

Is Silicon a Semiconductor?

Yes, silicon is a semiconductor. It is one of the most widely used materials for this purpose, especially in electronic devices. Semiconductors, like silicon, have electrical conductivity that falls between that of a conductor and an insulator. This property allows them to be used in a wide range of electronic components, such as transistors, solar cells, and integrated circuits. Silicon's semiconductor properties are enhanced by doping, which involves adding small amounts of other elements to modify its electrical properties.

Why Is Silicon Used Extensively in Semiconductor Electronics?

The most important element in a computer is silicon. Its low resistance is needed for computing, and silicon is the most common material for semiconductors. Its low resistance also means it's a good material for computers. In addition, silicon is a very stable atom, and it doesn't break easily under high temperatures. The high temperature resistance makes it an excellent choice for semiconductors. In addition, it's a good choice for solar panels and other devices, so it's a great option for solar power.

Silicon is the second most abundant element in the world, accounting for about 28% of the earth's crust. And is the most cmmon metal in the world. The element is very easy to process and purify, making it ideal for the semiconductor industry. Its high purity and single crystal structure also make it an attractive choice for electronic components. Its other benefits include its comparatively low cost and ease of extraction. Here's why silicon is used in electronics.

In addition to being abundant, it is also very easy to process silicon into wafers, and its manufacturing techniques are becoming more eco-friendly. It's least affected by water, acid, and steam, and its chemical nature makes it more reliable in high-temperature settings.

Because of silicon's semi-conducting properties, the material is widely used in electronics. It's also used in the energy sector, where it's an essential component of solar panels and photovoltaic cells. Because it's so abundant, silicon is relatively easy to obtain. However, its relative rarity makes it difficult to purify it in nature. As a result, it requires man-made processing to make it suitable for electronics.

Because of its high availability, silicon is inexpensive and plentiful. While silicon can be purchased in many places, it is not widely available. Even though it's abundant, it's difficult to find pure silicon. Since oxygen is an essential component of most silicon compounds, it must be purified to obtain a usable substance. By using modern technologies, semiconductors can be made in an environmentally-friendly manner. This makes silicon even more attractive to manufacturers.

Silicon is a very versatile material. It can be found in nature in its most natural form in sand and quartz. It is a cheap and environmental material, which makes it a very popular choice in the electronics industry. Because it is cheap, it is also scalable for big production facilities. In addition, it's a highly reliable insulator even in high temperatures. The fact that silicon is plentiful in the earth's crust makes it an excellent choice for semiconductors.

Despite its low availability, silicon is abundant in the earth's crust, where it is found in sand and quartz. It can be used to make semiconductors, which are very expensive. Unlike gold or copper, it's also a good candidate for the raw material for a high-tech product, because it's so easy to refine it. But it's not only useful for electronics; it's also environmentally-friendly, too.

As an insulator, silicon is a great choice for semiconductors. It allows for a small amount of electricity to pass through it, but it is a great choice for a variety of applications, including electronics. In the energy sector, silicon is used in photovoltaic cells. Because it's a semiconductor, it can conduct electricity under some conditions but not at other. The electrical properties of silicon can be altered through the process of doping.

Silicon is an element found in the earth's crust. It's the cheapest material with these properties, which makes it the most popular choice for semiconductors. It's also used in the PC and smartphone industry. Besides electronics, silicon is found in a variety of everyday products and is the main component in most building materials. In addition to electronics, it's also used in PCs and smartphones. It's not only cheap and environmentally friendly, but it is also available in large quantities.

Why is Silicon, and Not another Material Widely Used in Semiconductors?

The simple answer is price. Silicon is the second most abundant material on earth after Carbon.

The simple answer is price. Silicon is the second most abundant material on earth after Carbon.

Eventually other materials, will have to be used to get faster computers and smaller components etc. But these other materials are far more expensive to procure and tooling is limited. One 100mm Silicon Wafer Prime Grade in large quantities can be sold for around $10.00 each or less. Silicon Carbide, a much stronger material is very difficult to work with and, currently, costs 30x as much as the same sized silicon wafer!

But you will most likely see more expensive electronics that can do more in the next ten years, but you will pay a premium over silicon.

This may create a socials problem as wealthier people would be able to afford a $10,000.00 laptop while the rest will have to make do with handheld devices.

What the outcome will be is beyond the scope of this web site. But it will be interesting to watch.

![]() structure, and for what we know now we need a P-doped semiconductor wafer with <100> orientation, but if it couldn't be obtained we could change the process for another type of wafer, because we are in the early stages of the project.

structure, and for what we know now we need a P-doped semiconductor wafer with <100> orientation, but if it couldn't be obtained we could change the process for another type of wafer, because we are in the early stages of the project.