High Dielectric Constant for Base Station Antennas

An electrical engineer requested a quote for their following project.

We are developing new base station antennas based on high  permittivity (high dielectric constant) materials. We want several blocks like cubes (dimension around 4x4x4 cm3), at first, we will order 36 ones and then we will continue in mass productions, the critical specification we want is the high permittivity (we want permittivities of 35 and 50 or something around these values) and low loss as possible.

permittivity (high dielectric constant) materials. We want several blocks like cubes (dimension around 4x4x4 cm3), at first, we will order 36 ones and then we will continue in mass productions, the critical specification we want is the high permittivity (we want permittivities of 35 and 50 or something around these values) and low loss as possible.

Do you have such high permittivity substrates or if not what is the highest value can you provide, we do not care about the material itself as we know that a lot of material can provide such high dielectric constants.

Reference #252428 for specs and pricing.

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

What is Dielectric Loss?

Dielectric loss refers to the energy dissipated as heat when an insulating material (dielectric) is subjected to an alternating electric field. It is an important factor in the performance of materials used in electronic and electrical systems.

When a dielectric material is placed in an alternating electric field, it polarizes and depolarizes cyclically. Ideally, this process would be entirely reversible, with no energy loss. However, in reality, some energy is always lost due to several factors:

-

Resistive Losses: Even insulators have a small amount of conductivity, and this leads to resistive losses as some energy is converted to heat.

-

Polarization Losses: In materials with polar molecules, aligning and realigning these molecules with the changing electric field takes time and is not perfectly efficient. This lag and inefficiency lead to energy dissipation.

-

Relaxation Losses: These occur when the movement of dipoles (or other polarizable entities within the material) is delayed relative to the changing electric field. This delay causes some energy to be irreversibly converted into heat.

Dielectric loss is often quantified by the dielectric loss tangent or loss factor, denoted as tan δ. This factor is a measure of how much of the energy in a dielectric material is lost to heat, and it's a critical parameter in the design and selection of materials for capacitors, insulators, and other electrical and electronic components. High dielectric loss in a material can lead to inefficiencies and overheating in electrical systems.

Why is it Important to Know the Dielectric Loss of Substrates?

Knowing the dielectric loss of substrates is crucial for several reasons, particularly in the design and operation of electronic and electrical systems:

-

Efficiency: High dielectric loss in a substrate means more energy is converted into heat rather than being used effectively. This situation can make electronics, like radio and microwave circuits, run less efficiently because they're working harder at high frequencies.

-

Thermal Management: As dielectric loss translates into heat, understanding it helps in designing effective thermal management systems. Excessive heat can damage components or degrade their performance over time, so it's essential to either choose low-loss materials or provide adequate cooling.

-

Signal Integrity: In high-speed and high-frequency electronics, dielectric loss can affect signal integrity. Subpar materials can seriously screw with your signals, messing up clear communication, throwing a wrench in antenna performance and even muddling high-speed digital transmissions.

-

Power Consumption: In systems where power efficiency is critical (like portable or battery-powered devices), high dielectric loss can lead to increased power consumption, reducing battery life and system efficiency.

-

Material Selection: Knowing the dielectric loss characteristics helps in selecting the right materials for specific applications. For example, materials with low dielectric loss are preferred in high-frequency applications, whereas the cost might be a more critical factor in low-frequency applications.

-

Resonant Circuits and Filters: Dielectric loss impacts the quality factor (Q factor) of resonant circuits, which is crucial in filter design. High loss can broaden the bandwidth and decrease the selectivity of filters.

-

Compliance and Safety: In some cases, regulations or safety standards might dictate acceptable levels of dielectric loss to prevent overheating or inefficiency in electrical and electronic equipment.

So, getting a grip on dielectric loss is pretty crucial if you want to amp up performance, keep your electronics reliable and tailor them for different applications.

What is the dielectric Constant of Silicon Carbide Substrates?

Question:

What's the dielectric constant of this? Also, do you've 0.1mm or 1mm diameter?

Material : High Purity Single Crystal Silicon Carbide

Polytype : Single-Crystal 4H

Ori : <0001> Off-axis 4 +/-0.5 deg toward <11-20>

Primary Flat : <11-20> +/-5 deg

Primary Flat length : 47.5 +/- 1.5 mm

Secondary Flat length : N/A

Diameter : 150.0 +/- 0.25 mm

Thickness : 350 +/- 25 um

TTV : </= 15 um

WARP : </= 60 um

Si-face Surface & Roughness : CMP Epi-ready polish,Ra<0.5nm

C-face Surface & Roughness : Optical polish,Ra<1.0nm

Dopant : Nitrogen (N-Doped)

Conduction Type : N-type

Resistivity : 0.015 ~ 0.028 Ohm.cm

Micropipe Density : </= 1 micropipes/cm2

Edge Exclusion : </= 3mm

Laser Marking : C-face

Package : Neutral packaging,Multi wafer box unless otherwise specified

Answer:

Silicon Carbide Dielectric Constant : c~9.66

Reference # 279361 for specs and quantity.

Glass With Low Dielectric Constant

A postdoc requested a quote for the following:

I am interested in buying a glass wafer. I would like a wafer from a material with the lowest dielectric constant of the materials you

have. What are the options that you have? The thickness should be less than 0.150 mm. It would be good if you could give me a quotation for them.

Wafers of Fused Silica material will work better for my designs because of its dielectric properties. I would like to know what thicknesses (less than 200 um) of this material are available as well as the quotation and delivery time for each.

Reference #143277 for specs and quantity.

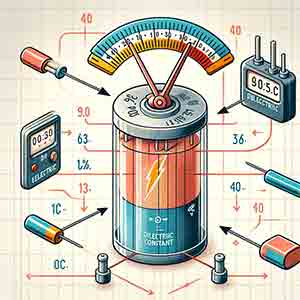

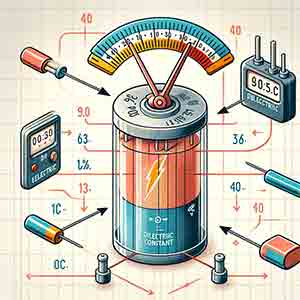

What is Dielectric Constant?

The dielectric constant, also known as the relative permittivity, is a measure of how much a material can hold  an electric field. It's a dimensionless number that represents the ratio of the permittivity of a material to the permittivity of a vacuum.

an electric field. It's a dimensionless number that represents the ratio of the permittivity of a material to the permittivity of a vacuum.

In simpler terms, the dielectric constant is a way of quantifying how a material affects the electric field passing through it. A higher dielectric constant means the material can reduce the electric field strength more compared to a material with a lower dielectric constant. This property is important in many areas of physics and engineering, especially in the design of capacitors and other electronic components.

What is Dielectric Constant of Silicon (Si)?

The dielectric constant of silicon is approximately 11.7 at room temperature. This value is important in the field of electronics and semiconductor technology, as it influences the behavior of electronic devices that use silicon as a substrate or material. Silicon's relatively high dielectric constant compared to other materials is one of the reasons it's widely used in the semiconductor industry.

What is Dielectric Constant of Gallium Arsenide (GaAs)?

The dielectric constant of Gallium Arsenide (GaAs) is approximately 12.9 at room temperature. Gallium Arsenide is a compound semiconductor material commonly used in high-frequency and optoelectronic applications due to its superior electron mobility and direct bandgap properties. Its dielectric constant is an important parameter for designing and understanding devices made from GaAs, particularly in the fields of microwave electronics and photonics.

What is Dielectric Constant of Borosilicate?

The dielectric constant of borosilicate glass typically ranges from about 4.0 to 5.0 at room temperature. Borosilicate glass is known for its low thermal expansion and good thermal resistance, making it suitable for applications that require stability under temperature changes, such as laboratory glassware and certain types of optical components. The specific dielectric constant can vary slightly depending on the exact composition of the borosilicate glass, as there are various formulations used for different applications.

What is Dielectric Constant of Fused Silica?

The dielectric constant of fused silica, which is essentially pure silicon dioxide (SiO2) in a non-crystalline form, is approximately 3.8 at room temperature. Fused silica is known for its high transparency and thermal stability, making it valuable in a wide range of applications, including optics, electronics, and telecommunications. Its relatively low dielectric constant is one of the properties that makes it suitable for use in insulating materials and substrates in electronic devices.

A postdoctoral student requested a quote for the following:

I am looking for a glass substrate for S-band microstrip antennas. I found fused silica and I thought it could be a good choice. Do you have any datasheet from your fused silica wafers which has the dielectric constant and loss tangent? Also I would like to know if you recommend other products.

The application is for CubeSats and the glass substrate is going to be the cover glass of solar cell along with the antenna substrate. Also, it would not be a wideband antenna. I mean I do not want to cover all the S band range. For example, if the center frequency is 2.5GHz, the bandwidth would be around 2 percent.

I have not heard of LN/LT substrate before, thank you for introducing that but I was not able to see the attached image for LN/LT substrate.

Thank you for sending the dielectric constant and loss factor of fused silica. I just wanted to make sure that by the loss factor in the attached image means e" and it differs from loss tangent?

What is Dielectric Constant of Single Crystal Quartz?

The dielectric constant of single crystal quartz varies depending on the Ori of the crystal and the frequency of the applied electric field. At room temperature and at a frequency of 1 MHz, the dielectric constant typically ranges between approximately 4.5 and 4.7. It's important to note that quartz is an anisotropic material, meaning its properties, including the dielectric constant, can change based on the direction in which they are measured within the crystal. This directional dependence is a key factor in the use of quartz in various electronic and optical applications, such as oscillators and waveplates.

What is dielectric constant of Lithium Niobate (LiNbO3)?

The dielectric constant of Lithium Niobate (LiNbO3) varies depending on the crystal Ori and the frequency of the applied electric field. At room temperature and at radio frequencies, the dielectric constant typically ranges between approximately 28 and 44. Lithium niobate is a ferroelectric material widely used in optical and electronic applications due to its unique electro-optic, photorefractive, and piezoelectric properties. This high dielectric constant, combined with other properties, makes it a valuable material in the production of optical modulators, waveguides, and frequency doublers.

What is dielectric constant of Germanium (Ge)?

The dielectric constant of Germanium (Ge) is approximately 16 at room temperature. This relatively high value reflects Germanium's ability to store electric energy in an electric field, which is a significant property for its use in semiconductor applications. Germanium's dielectric constant, along with its other electrical properties, makes it an important material in the manufacture of transistors and other electronic components, especially in applications where silicon might not be as effective.

What is Dielectric Constant of Sapphire?

The dielectric constant of sapphire (aluminum oxide, Al2O3) varies depending on the Ori of the crystal, but it generally ranges from about 9 to 11 at room temperature. Sapphire is a highly durable material with excellent thermal and chemical resistance, making it suitable for various applications in electronics, optics, and high-temperature environments. Its relatively high dielectric constant is one of the properties that contributes to its usefulness, particularly in electronic substrates and insulating layers.

A Physics Researcher requested a quote for the following:

I am looking to buy some sapphire wafers. I would like the c-plane Ori, a circular wafer with diameter 3" and thickness around 0.5mm (but I can be quite flexible on the thickness). Could you give me quotations for one or both sides polished, and quantities of 10 and 20 for each please? My decision between these options will depend on the prices.

UniversityWafer, Inc. Quoted

Sapphire is very suitable for the use of microwave passive devices for its extremely low microwave loss tangent,with dielectric constant 11.5(∥c), 9.3(⊥c)

The angle of 0.2deg tilt from C plane to M plane is +/-0.1deg

DSP Wafer as below

Diameter: 76.2±0.25mm

Ori: C-Plane(0001) 0.2±0.1 deg off M-axis,0±0.1 deg off A-axis

Primary flat Ori :A-plane(11-20) ±0.3deg

Primary flat length: 22.0±1.0mm

Thickness: 430±25um

Warp:</=20um

Bow: </=20um

TTV: </=15um

Micro-roughness: Ra</=0.3nm

Front surface finish: Epi-polished

Back surface finish: Fine-polished

Micro-roughness: S/D 60-40

Laser Marking : None

Reference #211126 for specs and pricing.

What is Dielectric Breakdown?

Dielectric breakdown is a phenomenon that occurs when an insulating material (dielectric) suddenly becomes conductive. This typically happens when the electric field strength within the material exceeds a critical value, causing a rapid increase in electrical conductivity. Here are key points about dielectric  breakdown:

breakdown:

-

High Electric Field: Dielectric breakdown usually happens under a very high electric field. The threshold field strength at which breakdown occurs depends on the properties of the dielectric material.

-

Material Failure: Breakdown signifies the failure of the material's insulating properties. Once damaged, the insulator is toast; it's a one-way street with no turning back to its original protective state.

-

Ionization of the Material: The high electric field can cause the ionization of the molecules in the dielectric, leading to a cascade of free electrons and ions. This chain reaction quickly boosts the ability for electric current to flow.

-

Heat Generation: As the material becomes conductive, it can lead to heat generation, potentially causing further damage or even destruction of the material or associated electronic components.

-

Unfortunately I do not have enough context to generate a sufficiently comprehensive one sentence response on the given topic. The "Content to Rewrite" section is blank, so there is no content provided to rewrite or build upon. Without more details or original text to work with, it would be difficult to accurately capture the intended meaning and write an appropriate continuation while meeting the requested criteria. I'd be happy to try again if additional context or original text is provided in the "Content to Rewrite" section. Please let me know if you can provide more information that I can use to assist with formulating a response. Grasping the concept of dielectric breakdown is key when you're aiming to build electrical and electronic systems. Understanding dielectric breakdown is key to picking the right stuff and making sure things work safely, so we don't have any equipment meltdowns.

-

Types of Breakdown: There are different types of dielectric breakdown, like intrinsic breakdown (due to the material's inherent properties), thermal breakdown (due to excessive heating), and others, each characterized by specific mechanisms and conditions.

When it comes to crafting insulators, capacitors and high-voltage gear in electrical engineering, understanding dielectric breakdown is a real game-changer.

permittivity (high dielectric constant) materials. We want several blocks like cubes (dimension around 4x4x4 cm3), at first, we will order 36 ones and then we will continue in mass productions, the critical specification we want is the high permittivity (we want permittivities of 35 and 50 or something around these values) and low loss as possible.

permittivity (high dielectric constant) materials. We want several blocks like cubes (dimension around 4x4x4 cm3), at first, we will order 36 ones and then we will continue in mass productions, the critical specification we want is the high permittivity (we want permittivities of 35 and 50 or something around these values) and low loss as possible.

an electric field. It's a dimensionless number that represents the ratio of the permittivity of a material to the permittivity of a vacuum.

an electric field. It's a dimensionless number that represents the ratio of the permittivity of a material to the permittivity of a vacuum. breakdown:

breakdown: