Substratates Used for MALDI Imaging

We carry the wafers you need for all your MALDI imaging project.

Simply let us know what you need or send us your questions for an immediate answer.

Reference #209450 for pricing or buy online and start researching today!

What ITO Wafer Spec is Used for MALDI Imaging?

A Phd candidate was looking at product ID 2277 (ITO coated slides, 75 x 22 x 0.7 mm, 15-20 Ohm/sq) for our MALDI imaging experiments.

Queston:

What indium tin oxide specs work best for maldi?

Have they (ITO Substrates) already been used with MALDI instruments?

Would it be possible to receive a sample (1 or 2) slides, before order a larger number?

Answer:

Indium tin oxide (ITO) is often used as a conductive substrate in MALDI experiments due to its excellent electrical conductivity, optical transparency, and ability to support sample deposition. Choosing the right ITO specifications can significantly impact MALDI performance. Here are the key specifications to consider:

Key Specifications for ITO in MALDI

-

Sheet Resistance:

- Typical range: 10–50 Ω/sq.

- Lower resistance ensures efficient charge dissipation, which is crucial for MALDI ionization and mass spectrometry analysis.

-

Transparency:

- Optical transparency > 80% in the UV-visible range (300–700 nm) is ideal, especially for UV-MALDI where a laser (often UV) irradiates the substrate.

- Transparency allows monitoring the sample deposition and ensures proper laser penetration to interact with the matrix.

-

Surface Roughness:

- RMS roughness < 5 nm is preferred.

- A smoother surface ensures uniform sample deposition, which is critical for reproducibility and signal quality in MALDI-MS.

-

ITO Thickness:

- Typical range: 100–200 nm.

- Thicker films provide better conductivity, but thinner films may offer improved transparency.

-

Substrate Material:

- Glass or quartz substrates are commonly used for ITO coatings in MALDI.

- Glass is cost-effective, while quartz offers higher UV transparency if needed for specific laser wavelengths.

-

Hydrophilicity:

- A hydrophilic ITO surface (contact angle < 30°) improves the adhesion and spreading of the MALDI matrix and analyte, leading to better sample preparation.

-

Chemical Stability:

- Ensure the ITO is stable under the solvents used for MALDI matrix deposition (e.g., acetonitrile, methanol, water, etc.) to prevent degradation or delamination.

Practical Considerations

- Matrix Compatibility: Choose an ITO surface that allows good interaction with the specific matrix used (e.g., DHB, CHCA) for uniform crystallization.

- Spot Size and Uniformity: Ensure the ITO surface supports consistent crystal formation over the laser's focal area.

- Custom Coatings: Some applications may benefit from functionalized ITO surfaces to enhance analyte-matrix interactions.

By optimizing these parameters, you can achieve better signal intensity, resolution, and reproducibility in MALDI experiments.

So the following will work fine for MALDI

15-20 ohm/sq ITO coated polished glass

Surface: Polished grade

Size: 75mm x 22mm x 0.7mm

Reference #209450 for specs and pricing.

What is Matrix-Assisted Laser Desorption/Ionization (MALDI)?

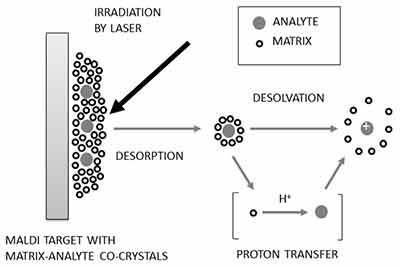

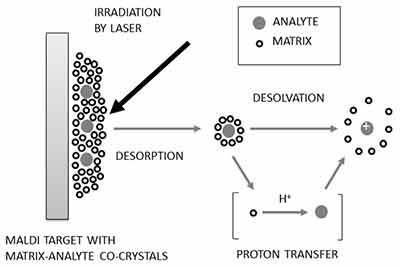

Matrix-Assisted Laser Desorption/Ionization (MALDI) is a soft ionization technique used in mass spectrometry to analyze biomolecules, large organic molecules, and polymers. It is especially valuable for studying compounds that are difficult to ionize or vaporize without decomposition. Here’s how MALDI works:

Key Components and Process

-

Matrix Preparation:

- The sample to be analyzed is mixed with a chemical matrix, typically a small organic compound that absorbs laser light well.

- The matrix acts as an energy absorber and helps ionize the analyte while protecting it from decomposition.

- Common matrix compounds include sinapinic acid, α-cyano-4-hydroxycinnamic acid (CHCA), and 2,5-dihydroxybenzoic acid (DHB).

-

Sample Deposition:

- The matrix and analyte mixture is deposited onto a metal plate or target and allowed to dry.

-

Laser Desorption/Ionization:

- A pulsed laser, often in the UV range, irradiates the sample, causing the matrix to absorb energy and ablate.

- The matrix transfers energy to the analyte molecules, desorbing them into the gas phase while simultaneously ionizing them.

-

Ion Acceleration:

- The ionized analyte molecules are accelerated in an electric field and introduced into a mass spectrometer.

-

Mass Analysis:

- The mass spectrometer measures the mass-to-charge ratio (m/zm/z m/z) of the ionized analyte molecules. Time-of-flight (TOF) mass analyzers are commonly used in MALDI-MS.

Applications

- Proteomics: Identification and characterization of proteins, peptides, and their modifications.

- Biomolecule Analysis: Study of DNA, RNA, lipids, and carbohydrates.

- Clinical Diagnostics: Detection of biomarkers and pathogens.

- Polymer Analysis: Examination of synthetic and natural polymers.

- Pharmaceuticals: Drug discovery and analysis of complex formulations.

Advantages

- Soft Ionization: Minimizes fragmentation, allowing the analysis of intact large molecules.

- High Sensitivity: Detects small amounts of analytes.

- Wide Range: Suitable for molecules with a broad mass range, from small peptides to large polymers.

- Speed: Rapid data acquisition and analysis.

Limitations

- Matrix Interference: Matrix signals can overlap with analyte peaks, complicating analysis.

- Sample Preparation Sensitivity: Requires precise preparation to ensure reproducibility.

- Limited Quantification: Often less quantitative compared to other mass spectrometry techniques.

MALDI is an essential tool in analytical chemistry, biochemistry, and molecular biology for its ability to analyze complex and fragile biomolecules.

How is Indium Tin Oxide (ITO) Used for MALDI imaging Experiments?

Indium Tin Oxide (ITO) can be used as a substrate for MALDI (Matrix-Assisted Laser Desorption Ionization) imaging experiments in mass spectrometry. Here's how it works:

-

Coating: The first step is to coat the ITO substrate with a thin layer of a suitable matrix material. The  matrix is a compound that facilitates the ionization of the analyte molecules, which are the molecules of interest that the researcher wants to detect and identify. Common matrix materials used in MALDI imaging experiments include α-cyano-4-hydroxycinnamic acid (CHCA) and 2,5-dihydroxybenzoic acid (DHB).

matrix is a compound that facilitates the ionization of the analyte molecules, which are the molecules of interest that the researcher wants to detect and identify. Common matrix materials used in MALDI imaging experiments include α-cyano-4-hydroxycinnamic acid (CHCA) and 2,5-dihydroxybenzoic acid (DHB).

-

Sample Deposition: After the matrix is applied, the analyte molecules are deposited onto the surface of the matrix. This is typically done using a spotting technique, where a small amount of the sample solution is placed on the surface of the matrix-coated ITO substrate.

-

MALDI Imaging: Once the sample has been deposited onto the substrate, the substrate is inserted into the mass spectrometer. A laser beam is then used to ionize the sample molecules, which are then detected and analyzed by the mass spectrometer. The ITO substrate acts as a conductive surface that helps to generate a homogeneous laser beam and facilitate ionization.

The advantage of using ITO as a substrate for MALDI imaging experiments is that it has a high electrical conductivity, which allows for efficient ionization of the analyte molecules. Additionally, the transparency of ITO allows for visualization of the sample during the deposition process, which helps to ensure accurate and precise placement of the sample on the substrate.

matrix is a compound that facilitates the ionization of the analyte molecules, which are the molecules of interest that the researcher wants to detect and identify. Common matrix materials used in MALDI imaging experiments include α-cyano-4-hydroxycinnamic acid (CHCA) and 2,5-dihydroxybenzoic acid (DHB).

matrix is a compound that facilitates the ionization of the analyte molecules, which are the molecules of interest that the researcher wants to detect and identify. Common matrix materials used in MALDI imaging experiments include α-cyano-4-hydroxycinnamic acid (CHCA) and 2,5-dihydroxybenzoic acid (DHB).