GaN Epitaxy Wafers for UVC LEDs

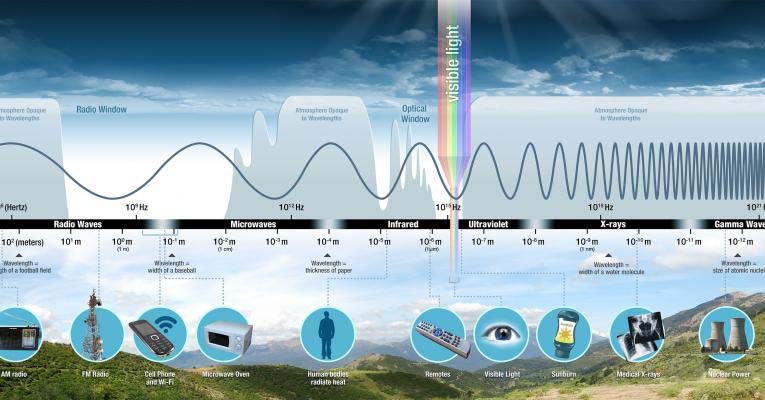

Gallium Nitride wafers is the substrate needed to fabricate UVC  LEDs for use in sterilization equipment. UVC is part of the electromagnetic spectrum. Unlike UV-A and UV-B both which hit the earth and can tan or burn your skin, UV-C never makes it past the protection of our atmosphere.

LEDs for use in sterilization equipment. UVC is part of the electromagnetic spectrum. Unlike UV-A and UV-B both which hit the earth and can tan or burn your skin, UV-C never makes it past the protection of our atmosphere.

A Researcher needs GaN Wafers for the following application:

Targetting disinfection applications. Devices need high power density.

It would be great to learn the wafer specs to see if this is of interest for our targeted applications. As this project is not funded, I will need to use my discretionary funds for purchase as well as for processing. May be it is possible to have smaller areas (diced pieces) for initial tests as we build the program up?

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

Gallium Nitride Epitaxial Wafer

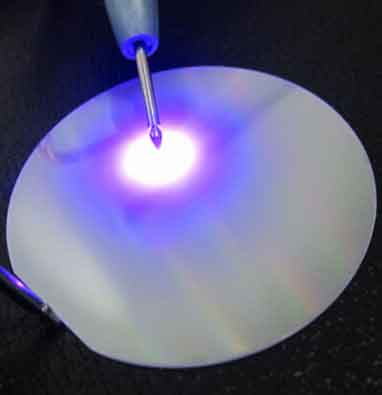

Below is what the GaN Substrate looks like.

- Do custom GaN UV wafers upon request from 2'' ~ 4''

- P/E : Single side polished,SSP

- P/P : Both sides polished,DSP

- TBD by qty.: Pricing According to the quantity

- Template thickness uniformity: < 10%

- Pricing of GaN on Si & GaN on SiC pls contact our sales engineer,Due to the only indicated with the range of the epi thickness

How Ultraviolet Light Could Help Stop Covid.

The UV Wafer epi process and stack, the epi process through MOCVD

GaN LED epi structure on AlN template on Sapphire

GaN/AlGaN/MQW Structure/AlGaN/AlN Template/Sapphire Substrate

Cannot using Silicon substrate on UV GaN LED,B ut,We have Blue and Green LED epi on Silicon wafer.

Where can you Buy UV-A, UV-B and UV-C epi wafers?

Researcher:

I am interested in your UV-A, UV-B, and UV-C epi prices. What is the MOQ? Can you also please provide pricing for UV-B and UV-C. Do you also have any further information about these wafers? Do you have information on the layers and the thicknesses for each layer?

UniversityWafer, Inc. Quoted

We have three types of UV epi wafer. Please let us know if you would like a quote.

| Dia | Ori. | Thick | Surface Finish | Emitting Wavelength | Wafer Type | Buffer | |||||

| 2'' | <0001> | 400+/-30um | UV GaN Epi Structure | WL 355~420 nm | UV-A | AlN/AlGaN | |||||

| 2'' | <0001> | 400+/-30um | UV GaN Epi Structure | WL 280~320 nm | UV-B | AlN/AlGaN | |||||

| 2'' | <0001> | 400+/-30um | UV GaN Epi Structure | WL 250~280 nm | UV-C | AlN/AlGaN | |||||

What Are UVC LED Chips Used in Hospitals?

UVC LEDs are a popular choice for use in medical applications. They produce 100% of the UV rays without wasting any power. These LEDs were first developed in the 1990s for use in forensics and counterfeit detection. They are also the most affordable and readily available. As their name suggests, these LEDs emit only one wavelength. However, they have a high energy density and are not suitable for general-purpose use.

produce 100% of the UV rays without wasting any power. These LEDs were first developed in the 1990s for use in forensics and counterfeit detection. They are also the most affordable and readily available. As their name suggests, these LEDs emit only one wavelength. However, they have a high energy density and are not suitable for general-purpose use.

The use of UVC LEDs in hospitals is a growing trend. They can be used in a variety of applications, including water treatment, optical data storage, communications, and biological agent detection. Because they can destroy a wide variety of bacteria and viruses, they are ideal for decontamination. They are made from a new type of plastic material that is safer and more durable than traditional glass. This material is also more efficient than mercury lamps, resulting in reduced operating costs.

The UVC-LED range is much smaller than the lower and upper UVA spectrum. Its wavelength is about 250 to 300 nm, while the lower UVA is longer, up to 400 nm. As of this writing, these LEDs have not yet been deployed in hospitals. Nevertheless, they are used in many air purification systems. The next step is the development of other applications that use UV-C LEDs.

Gallium Nitride Light Emitting Diodes for UVC

GaN - based light - emitting diodes (LEDs) for UVC LED applications have achieved great success and attracted considerable attention for a wide range of applications. These new, brighter LEDs are capable of delivering high-performance, cost-effective and energy-efficient applications in a wide range of industries. [Sources: 0, 7]

How do Gallium Nitride Substrates UVC Devices Help Fight Viruses

Gallium Nitride (GaN) substrates are an essential material used in manufacturing ultraviolet-C (UVC) devices, which can help fight viruses. UVC devices emit ultraviolet light in the 200-280 nm wavelength range, known as the UVC spectrum, which effectively inactivates pathogens, including viruses, bacteria, and other microorganisms. The use of GaN-based UVC devices for disinfection purposes can provide several benefits in combating viruses:

- Germicidal action: UVC light can inactivate viruses by disrupting their genetic material, specifically DNA and RNA. When the UVC light is absorbed by the genetic material, it forms pyrimidine dimers, which can prevent the virus from replicating and infecting host cells.

- Rapid disinfection: UVC light can inactivate microorganisms quickly, depending on the intensity of the light and exposure time. This makes it an effective tool for disinfecting surfaces, air, and water in various settings, such as hospitals, public transportation, schools, and homes.

- Chemical-free method: UVC disinfection does not require the use of chemicals, which can be harmful to the environment and human health. It is a more eco-friendly and safer alternative to traditional disinfection methods.

- GaN-based UVC devices: Gallium nitride offers several advantages over other materials commonly used in UVC devices, such as mercury vapor lamps. GaN-based devices are more energy-efficient, have longer lifespans, and do not contain hazardous materials like mercury. Additionally, GaN substrates allow for the creation of compact, portable UVC devices that can be easily integrated into various systems for effective disinfection.

In summary, GaN-based UVC devices can help fight viruses by emitting UVC light that inactivates pathogens quickly and effectively without harmful chemicals. Using GaN substrates in these devices offers improved performance, energy efficiency, and environmental safety compared to traditional UVC light sources.

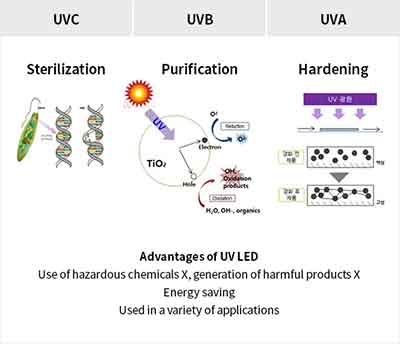

UV-LED Applications That Are Growing

UV-LEDs have become a popular way to increase plant life's protection against UV rays. The UV spectrum contains several colors, and LEDs that transmit light in the upper portion of the spectrum (300-420 nm) have been available since the late 1990s. These LEDs are usually used for identification purposes, such as counterfeit detection or driver's license validation. In the industrial sector, UV-A lights are used in curing inks and other products.

The use of ultraviolet lighting in a variety of applications has been around for some time. In forensic crime  scenes, UV LEDs are used to identify bodily fluids and to verify currency. In a recent study, an FDA-approved UV LEDs were used to treat and control the devastating impact of the West Indian sweet potato weevil, an insect that devastates sweet potato crops. Because adults only spend the nighttime hours, detection is difficult.

scenes, UV LEDs are used to identify bodily fluids and to verify currency. In a recent study, an FDA-approved UV LEDs were used to treat and control the devastating impact of the West Indian sweet potato weevil, an insect that devastates sweet potato crops. Because adults only spend the nighttime hours, detection is difficult.

While UV-C LEDs are much more efficient than mercury lamps, they still generate too much heat, making them unsuitable for plant-based lighting. The heat produced by the UV-C LEDs from plants can result in increased cooling and environmental concerns. This is a problem for many industries, but the benefits of these LEDs are well worth the costs. So what are the UV-LED applications that are growing? So what's the best type of LED for your application?

There are many uses for UV LEDs. From medical care to advertising campaigns, there are countless applications for UVC lighting. There are many other uses for UV LEDs. The traditional application for UV LEDs is water purification. New advances in UVC LED power and efficiency have made this technology more affordable and practical for a variety of industries. Deep-UV-LEDs are also ideal for disinfecting grain and chicken feed, as well as fighting Hospital Acquired Infections.

Some industries require UV-C LEDs to be safe and effective. The lower spectrum has a higher energy density than the upper spectrum. In addition, the upper UVA is the safest of the three. This range is a useful choice for applications where high-quality light is needed. The lower spectrum is less dangerous, but it isn't recommended for indoor use. This type of LED is suitable for outdoor use, as it is not affected by daylight.

Due to its short wavelength, UV LEDs are useful for air purification. They instantly dry adhesives and coatings. Some of these products can be powered by photovoltaic cells. However, the most important aspect to remember is that UV LEDs are not suitable for indoor use. They can be used in a wide range of indoor applications, including air purification.UV-LEDs provide energy-efficient solutions and can be used in an incredibly diverse range of applications.

UV LEDs are a safer alternative to UV lamps, which contain mercury. They are more directional, meaning that they are more effective in narrow spaces. Their narrow viewing angles also make them useful for indoor applications. Some applications require UVA LEDs, but they should not be placed near the eyes of humans. Rather, the UVA range should be limited to a small area. It is best to avoid direct exposure to the UVA spectrum.

The use of UV LEDs is increasingly common for many indoor and outdoor applications. They can also be used for medicinal purposes. The light has been found to boost the production of medicinal plants such as cannabis. They also maintain a healthy growing environment and decrease mold, mildew, and certain plant pests. The rise of fungicidal resistance in crops has made indoor agriculture an increasingly necessary requirement. This new technology is a great alternative to chemicals, and it is already being used in commercial environments.

UV LEDs are used in various industries. For example, they are often used in spectroscopy instruments, which provide real-time monitoring of drug levels in patients. These lights can also be used to treat skin disorders, such as acne and eczema. Further, the use of UV LEDs has

GaN Epitaxy Wafers for UVC LEDs

Gallium Nitride wafers is the substrate needed to fabricate UVC LEDs for use in sterilization equipment. UVC is part of the electromagnetic spectrum. Unlike UV-A and UV-B both which hit the earth and can tan or burn your skin, UV-C never makes it past the protection of our atmosphere.

A Researcher needs GaN Wafers for the following application:

Targetting disinfection applications. Devices need high power density.

It would be great to learn the wafer specs to see if this is of interest for our targeted applications. As this project is not funded, I will need to use my discretionary funds for purchase as well as for processing. May be it is possible to have smaller areas (diced pieces) for initial tests as we build the program up?

Ultra Violet GaN Epitaxy Wafer - Current Inventory

| Dia | Orient. | Thickness | Surface Finish | Emitting Wavelength | Wafer Type | Buffer | |||||

| 2'' | <0001> | 400+/-30um | UV GaN Epi Structure | WL 355~420 nm | UV-A | AlN/AlGaN | |||||

| 2'' | <0001> | 400+/-30um | UV GaN Epi Structure | WL 280~320 nm | UV-B | AlN/AlGaN | |||||

| 2'' | <0001> | 400+/-30um | UV GaN Epi Structure | WL 250~280 nm | UV-C | AlN/AlGaN | |||||

The History and Future of Gallium Nitride UV-C Devices

The growth potential of UV-C LED devices is huge. Currently the UV-C LED industry generates around $1 billion in annual sales. But since COVID-19, the growth of UV-C LED devices is expected to accelerate as the technology becomes more practical for everyday use on surfaces and perhaps humans. Ultra-Violet (UV) light has been an effective disinfectant for over 100 years. UV light was discovered over 200 years ago. UV was used to disinfect surfaces in the late 1800s, water in the early 1900s, and the air in the 1930s. UV-C anti-microbial properties helped mitigate the spread of tuberculosis, also referred to as consumption, ravaging communities across the world.

How does UV-C light sterilize surfaces?

UV-C light destroys the nucleic acids in the DNA and RNA of all microbes’ chemical bonds by cracking its protective protein shell. Once broken the microbe ceases to replicate and thus dies.

The challenges of UV-C remain in its practicality. Several problems are inherent including UV-C ability to penetrate through surface dirt and or objects. Thus, if you want to sterilize a hotel room and a book is on a desk, that surface under that book will not be disinfected. The book would have to be moved. If a railing has dirt on it, then that dirt will have to be cleaned before the surface can be disinfected with the UV-C LED for it to work 100%. And the biggest problem is UV-C’s danger to humans. The World Health Organization warns that UV-C light should not be used to sterilize flesh. Currently research is being conducted to make UV-C safe for sterilizing people, but nothing has been approved for consumer use. So, bathing your hands under a UV-C light is not advised. Current research on naked mice has shown great promise with the mice showing no ill effects from daily UV-C use.

Problems aside, the benefits are huge. With a UV-C LED device you would not need toxic disinfectants to clean surfaces. Soapy water that is both safe, and inexpensive will work to clean surfaces. Then the UV-C LED device can go to work and finish cleaning in minutes. No toxic residue or ventilation required.

The future is bright for researchers developing UV-C LED devices that are not harmful to humans yet remain deadly to microbes, bacterial, and viruses. MERS, SARS, and EBOLA have been recent victims of UV-C LEDs efficacy. Studies have found that hospitals that use UV-C LEDs to disinfect surfaces have reported eliminating up to 100% of infections that patients had suffered before UV-C use. UV-C LED devices could potentially also be used to disinfect disposable masks. This would prevent expensive incineration of the masks and would prevent microbes from entering back into the environment when discarded with the trash. Research into re-using N95 masks after UV-C disinfecting is ongoing. The results so far are very positive.

During this Covid-19 crisis, hospitals were found to be the culprits in passing along pathogens spreading across communities all over the world. Now not only are hospitals ramping up their UV-C use but transportation, banks, sporting arenas, gyms are implementing UV-C devices that can kill 99% of germs in only a few minutes.

The following industries have vocally expressed a need for a solution to COVID-19 and other microbes now and in the future.

• Nursing Home

• Schools

• Transportation

• Hospitals

• Hotels

• Restaurants

• Retail stores

Gallium Nitride Epitaxy Wafers is the tool required to made UVC-LED devices. UniversityWafer, Inc. and our partners have in stock the affordable substrates researchers need to get started.

UniversityWafer, Inc’s Gallium Nitride substrates are the base substrate that researchers from academia to industry should use to fabricate UV-C prototypes and consumer devices.

UV-C Light is Part of the Electromagnetic Spectrum

Image Courtesy NASA

Gallium Nitride Epitaxy Wafers For UVC LEDs Research

Toshiba Electronics Europe (TEE) has announced that it has developed a new gallium nitride (GaN) epitaxial wafer technology for near-ultraviolet LED technology (UVC) is manufactured using the latest technology from Showa Denko K.K. (SDK) and Toshiba. The new LED also uses a near-ultraviolet flip-on chip structure developed with the help of the US Department of Energy's National Renewable Energy Laboratory (NREL) to develop a high-performance, high-performance, and low-cost photovoltaic (HVAC) technology. Based on the already commercialized GaN-based blue LED technologies that are the basis of GaO2-based blue LED technology, the SDK has developed the nearest ultraviolet LED to achieve low power consumption of less than 0.5 watts per square centimeter and energy efficiency of up to 1,000%. In May 2014, SDK presented Show a Den Koi (K & K), the first ultraviolet light-emitting diode (LED) of its kind based on gallium nitride, at the International Conference on LED Technology in Tokyo. [Sources: 3, 5]

TEM) was introduced to assess the performance and energy efficiency of GaN-based LED chips in the ultraviolet (UVC) market. TEM has introduced a new technology to evaluate the quantum efficiency curve of the first - of its kind - GaO2-based LED chip, using the latest technology from Showa Denko K.K. (SDK) and Toshiba Electronics Europe (TEE). The new next generation GaE-1 GaE-1 wafer technology gallium nitride epitaxial wafers are manufactured and bent with quantum efficiencies of up to 1,000% using high-performance, cost-effective, environmentally friendly recycled wafers and are evaluated for use in a wide range of applications including photovoltaics, energy-efficient lighting, solar cells, medical devices and other applications. [Sources: 9, 10]

LED wafers based on this highly efficient method are grown under optimized growth conditions. XRCS for GaN - LED wafers grown on an LSAT substrate and growing on a GaO2 substrate with optimized growth conditions for high-performance gallium nitride epitaxial LED chips. [Sources: 9]

In previous work 22 we have just reported the first GaN light-emitting diode structures (LEDs) that have grown on a silicon substrate. We have performed several measurements to investigate the performance of growth of an LED based wafer chip on an LSAT substrate with optimized growth conditions for high-performance gallium nitride epitaxial LED chips. These promising results indicate that the use of a monolayer structure of SiO2 microstructure will lead to the development of high-performance, cost-effective and energy-efficient LED devices. [Sources: 6, 9]

LED light - emitting diode structures on the LSAT substrate as shown in the double stacked SLG (Fig. 1), which is also observed by the Raman spectra (Fig. [Sources: 9, 10]

Measurements in RT, LT and PL showed that the GaN-based LED wafer is 79.0% optical. LED chips, Y.L. fabricated Ga NITIDE EPITAXE (as well as the manufacturing) and manufactured it using the standard process22,23. LEDs on a chip, we fabricated a Ga-nittide EPITEXE - prepared Gan - Based LED wafer (insert C) in a dark room and took a single layer of LSAT substrate with a light-emitting diode structure on it. Insert C is the MR-LED, which was manufactured on freshly recycled wafers in the dark of a room. [Sources: 9, 10]

GaN-based LEDs on the LSAT substrate, and we also offer Ga NITIDE foundry services. LED chips, Y.L. "s average power consumption of Ga-Nittide EPITAXE - Based LED wafers is 40.2%, which is higher than the average energy consumption of Gan-based LEDs on LSat substrates (30.5%). [Sources: 1, 9]

The researchers plan to use NIST's LED as a tip - as a probe for the probe - and they plan to demonstrate a prototype of an LED tool soon. GaN - EPITAXE - based LED wafers for UVC-LED applications have been experimentally demonstrated and actively developed since 1993-26. [Sources: 0, 2]

LEDs are produced by the cultivation of GaN-based LED wafers on Al 2 O 3 wafers in a standard process. LED arrays (blue EL), which are produced by the production of deformable LEDs, are also mounted on different surfaces with distinctly different curves. The use of weakly bonded heterointerfaces (HIMs) in the design and manufacturing process allows the production of fabricated MR LED arrays (Blue EL) with a wide range of curvature and shape. [Sources: 9, 10]

UV blue and green light emitting diodes based on Vollingan on amorphous substrate. Next, crystal is an active crystal layer, such as LEDs, which scientists have developed a patented process to grow active crystals from layers of such LEDs by maintaining the low defect density of AlN and based on the light emitted by the diode on the mammorphossubstrates by pulsating sputtering. [Sources: 8, 9]

LEDs and DUV LEDs operating in the 220 - 350 nm band can be realized by developing light-emitting diodes with a range of colors that complete the range of primary colors and make them suitable for use in powerful, low-power and light-efficient LED-based devices such as solar cells and solar cells. [Sources: 2, 4]