Can you quote me on 25 4” DSP (100) Si with 100nm

low-stress nitride? Can you quote 25 4” DSP (100) Si both undoped bare wafers and the same wafers with 100nm low stress nitride?

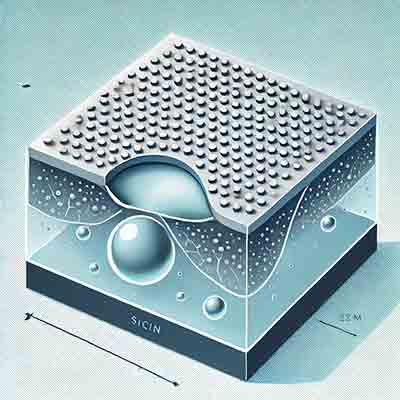

Substrates for Anisotropic Etching

Undoped Silicon Used For Anisotropic Etching

A semiconductor facilities manager requested the following quote.

Reference #123402 for specs and pricing.

Get Your Undoped Silicon Wafer Quote FAST! Or, Buy Online and Start Researching Today!

Why Does Boron Doped Silicon Wafer Pose A Problem For Anisotropic Etching?

Boron doping in silicon wafers can indeed pose challenges for anisotropic etching processes, particularly those that rely on etchants like potassium hydroxide (KOH) or tetramethylammonium hydroxide (TMAH). Here are some specific effects of boron doping on anisotropic etching:

-

Etch Rate Reduction: Highly boron-doped silicon has a significantly reduced

etch rate compared to lightly doped or undoped silicon. When the boron concentration exceeds a certain threshold (typically around 101910^{19} atoms/cm³), the etch rate in KOH or TMAH can be drastically reduced, making it difficult to achieve desired etch depths.

etch rate compared to lightly doped or undoped silicon. When the boron concentration exceeds a certain threshold (typically around 101910^{19} atoms/cm³), the etch rate in KOH or TMAH can be drastically reduced, making it difficult to achieve desired etch depths. -

Etch Stop Layer: Boron-doped silicon can act as an etch stop layer in anisotropic etching processes. This property is often used intentionally in silicon micromachining to create structures with precise thicknesses. The heavily doped p++ layer resists etching, allowing for accurate control of layer thickness.

-

Surface Morphology: The presence of boron can also influence the surface morphology of the etched silicon. The etched surface might become rougher due to the different etching characteristics of the doped regions compared to undoped regions.

-

Crystal Ori Dependency: The effect of boron doping on etching can be dependent on the crystal Ori of the silicon wafer. For example, the {111} planes in silicon are etched much more slowly than the {100} planes, and this anisotropy can be further modified by the presence of boron.

In summary, while boron doping can complicate anisotropic etching processes, it can also be used strategically in micromachining applications. Proper understanding and control of doping levels and etching conditions are essential to achieve desired outcomes in the fabrication process.

Why Are Unndoped Silicon wafers are Ideal for Anisotropic Etching?

Undoped silicon wafers are ideal for anisotropic etching due to several key reasons:

-

Uniform Etch Rates: Undoped silicon has consistent and predictable etch rates, which is crucial for achieving precise and uniform etching patterns. This consistency allows for better control over the etching process.

-

Smooth Surface Finish: The absence of dopants leads to a smoother etched surface, as there are no variations in the material's etch resistance. This results in cleaner and more defined geometric shapes.

-

No Etch Stop Layers: In undoped silicon, there are no regions with significantly different etch rates that can act as unintended etch stop layers. This ensures continuous etching without interruptions, which is essential for creating intricate structures.

-

Simpler Process Control: Etching undoped silicon simplifies process control since there is no need to account for variations in doping levels that can affect etch rates and outcomes.

-

Reduced Defects: Undoped silicon reduces the risk of introducing defects or impurities that could interfere with the etching process, leading to higher quality and more reliable results.

Overall, the use of undoped silicon wafers in anisotropic etching provides greater precision, control, and consistency, which are essential for high-performance microfabrication and semiconductor applications.