We have a request for quotation. The condition of item is like below. GaP(110) Crystal Size: 5x5mm or 10x10mm Thickness: 800µm~1 mm

Quantity:2pcs It is intended to be used in excitation wavelength "1030nm".

A scientist at a large device manufacturing plant requested a  quote for the following GaP substrates:

quote for the following GaP substrates:

We have a request for quotation. The condition of item is like below. GaP(110) Crystal Size: 5x5mm or 10x10mm Thickness: 800µm~1 mm

Quantity:2pcs It is intended to be used in excitation wavelength "1030nm".

For our specs and pricing reference #269809.

A PhD candiate requested a quote for the following GaP spec for their research paper.

I would like to request a quotation for an undoped (110) GaP crystal of 100 microns of thickness, with a surface area of 10 mm by 10 mm. In case you do not sell GaP crystals with such specifications, what is the smallest sized GaP wafer (in terms of thickness and surface area) that you sell?

Please reference RFQ#268345 for pricing.

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

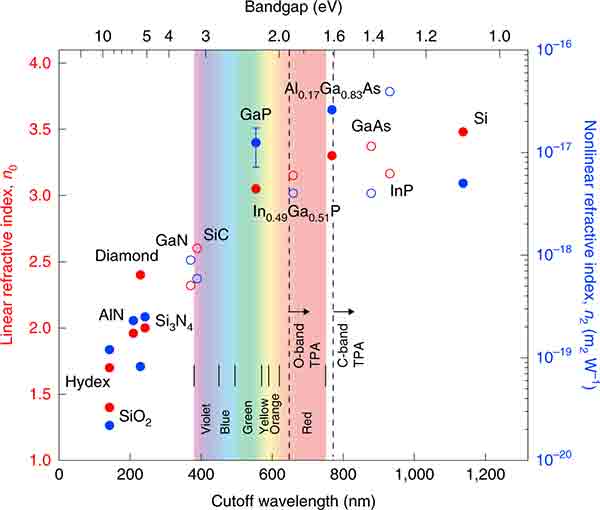

The most significant property of gallium phosphide that distinguishes it from other materials is its great optical clarity. When viewed through a scope, its wavy thickness shows bright bands in the spectrum. As seen from the figure above, the internal lines of single crystals are easily seen. In addition, the brilliance of the bands is enhanced if the device is viewed through an ultraviolet (UV) light source.

UniversityWafer, Inc. gallium phosphide wafers work great in solar cells and energy conversion, and can increase efficiency and produce more clean energy for our planet.

We are looking for a GaP <110> sample for THz generation. The ideal thickness is 0.5mm or 1mm.

The wafer should be polished on both sides and, it possible, AR-coated at 1030nm.

Solution:

GaP 25mm x 25mm Undoped (110)+/-0.5 deg 1,000 micron Double Side Polished Epi Ready

Other diameters available. Researcher was looking for least expenseive.

UniversityWafer provided researchers from Lawrence Berkeley National Laboratory with single crystalline (100) GaP wafers. These wafers were p-type doped with zinc. Their resistivity was 0.3 Ω cm with an Single Side Polished (SSP) epi-ready finish. This process was used to establish a new way to absorb light and produce clean, environmentally friendly energy.

Gallium phosphide (GaP) is a non-toxic and transparent semiconductor that is used in many telecommunications devices. It is said to have one of the best all-over performance. Gallium Phosphide is manufactured through a process called ionic diffusion. The material exhibits an extended band of hardness (between 0.73 and 0.75 micrometer) and superior electrical characteristic. One of its most important physical characteristics is its high correlation to gallium nitride, which is widely used in photovoltaic and optoelectronic applications.

The ganthanic compound has the look of tiny black dots. The crystals have a bluish color, which can be attributed to high solvation of the gallium indium phosphide in the silicon substrate. Undoped single crystal devices also exhibit clear red wafers, while highly doped single crystal devices seem black, because of free-Carrier absorption.

Gallium phosphide (GaP) exhibits some unique physical properties that make it ideal for use in photovoltaic systems, electronics, and energy transfer. It has high solubility, which makes it soluble in water. Solubility gives it the ability to diffuse into other liquids with low-molecular weight. This property makes it possible to build wafers from small solids such as silica and quartz. In addition, Undoped Silicon Wafers (Si) is insoluble in water and separates readily between Si and water. Single-crystal devices based on gallium phosphide (Ig) are capable of producing electrical power, whereas bulk Icos based on Pd are unable to do so.

Gallium phosphide can be formed in various ways. It can be formed from gallium nitrate (CHN) or gallium phosphate (DIP), which is the common semiconductor wafer substrate used in industries. Gallium phosphate is inexpensive and commonly found in many industries. However, its thermal stability is poor. Moreover, its high vapor transmission rate reduces its cost.

In contrast, gallium phosphide is a semiconductor compound that is formed directly from Gallium Nitride (GaN). Its optical clarity is superior to that of the former. Hence, it exhibits superior performance in applications requiring short-wave transmission and energy conversion. Moreover, gallium phosphide exhibits good electrical and optical properties, which are unique in the context of semiconductor materials. It is also used in medical devices because of its anti-toxicity property.

Silicon carbide is a white crystalline powder and was initially developed as an alternative to gallium phosphide due to its high purity. Silicon carbide has low density, which makes it a suitable material for dosing equipment. Silicon carbide can be used as a substitute for Pd as it yields higher purity. The electrical and optical properties of silicon carbide make it a good semiconductor compound for optoelectronic applications.

Tungsten trioxide is a popular choice for coloring semiconductors due to its colorless, smooth, and highly conductive property. However, tungsten trioxide's high melting point makes it a poor choice for use in electronics as it can easily get bubbled. A novel method called dopant dissolution is gaining popularity for preparing semiconductor materials such as gallium phosphide using common dietary products. Dopant dissolution uses a solution of potassium in a doped mixture of tungsten trioxide crystals.

Gallium phosphide, Silicon Carbide (SiC), Indium Phosphide (InP) wafer thicknesses, and doping equipment are important components in desktop testing systems. These testing supplies help in quality assurance, yield testing, and stability testing of semiconducting systems. Moreover, these testing supply products have low cost of manufacturing, easy handling, flexibility, safety, durability, and value for money. Overall, the benefits of using gallium phosphide, silicon carbide, indium phosphide wafer thicknesses, and doping equipments are considerable.

Gallium phosphide wafers are widely used in semiconductor devices. The material's transparent nature makes it an ideal choice for the fabrication of LEDs and other high-efficiency devices. However, this material is not free from defects. As a result, it is often used in LEDs at relatively low costs. Nevertheless, its optical properties are also limited, which makes it less suitable for high-end applications.

Gallium phosphide wafers are made using a single-crystal GaP. These are grown using a LEC method, using 6N high-purity materials. This semiconductor material is widely used in displays and red LEDs. Because of its excellent quality and high-performance properties, this material is commonly used in display elements and LCD backlights.

Gallium phosphide is a compound semiconductor with a broad indirect band gap. Its crystal structure is similar to silicon and the lattice constant is 0.545 nm. It has high solubility, allowing electrons to diffuse into low-molecular-weight liquids, and is insoluble in water. Due to its favorable properties, gallium phosphide is widely used in optical systems.

UniversityWafers provides single-crystal GaP gallium phosphide wafer, grown using a six-nanometer process. This material is very well-made and is used as a yellow and red LED. In addition, it is also widely used in LCD display elements and the backlight of LCDs. Its good quality makes it a great choice for display elements.

Gallium phosphide is a polycrystalline compound semiconductor that has a wide range of applications. It is a white-gray material that has a small indirect band gap of 2.26 eV. Unlike silicon, gallium phosphide has a high refractive index. It is a good choice for display elements and LCD backlights.

Gallium phosphide is a nonlinear compound semiconductor with a broad range of applications. Its indirect bandgap is 2.26 eV, making it one of the most accessible semiconductor materials. The material is transparent to visible light and long-infrared radiation. Its high-resolution transparency makes it an ideal choice for medical devices. If you're looking for a semiconductor, this is an excellent choice for your project.

Gallium phosphide is a compound semiconductor. Its indirect band gap is 2.26 eV (300K). Its n-type and p-type semiconductors are characterized by a narrower band gap. Consequently, these two materials are very useful in a wide variety of applications. Its p-type counterparts have an increased ability to absorb ultraviolet light.

In addition to being useful for LEDs, gallium phosphide wafer is also a popular material for solar cells. These devices are used in LED manufacturing and are widely available in the market. This material is available in several different types, and its benefits include the ability to produce clean energy. The compound semiconductors can be fabricated with ease. If you're interested in making your own LEDs, gallium phosphides are a good choice.

The use of gallium phosphide wafer is widespread. It can be used as an LED, which is a popular type of LED. Its high optical property allows it to be used in a number of different electronic devices. The high optical quality of these components means they're highly versatile. If you're looking for a semiconductor that can perform in many applications, gallium phosphide is an excellent choice.

As a result, gallium phosphide wafer is an important component of many desktop testing systems. Its n-type and p-type semiconductors are used for laser diodes and other devices. The material's low density makes it suitable for dosing equipment. Its high optical and electrical properties make it a perfect choice for optoelectronic applications.

Gallium phosphide is an extremely versatile semiconductor. It is an excellent choice for use in solar cells and in solar panels. Its high optical properties make it an ideal material for many applications. The material's low resistance and high electrical conductivity makes it the perfect semiconductor for electronic and photovoltaic devices. A wide variety of products can be manufactured with gallium phosphide wafer.

A scientists requested the following:

"I need FRHZ Si 0.5mm and 1 mm thick with 50 mm diameter. for THz applications. need to block plasma and allow only the THz radiation. Can you please send the quotation."

UniversityWafer, Inc. Quoted:

We have GaP wafers for THz application.

Please reference #266760 for pricing

A Postdoctoral researcher requested the following quote:

I'm looking for GaP wafers that are 110 or 100 oriented, as undoped as possible (i.e. resistivity as high as possible), and as thin of possible. I only need small pieces so wafer size is not a concern.

Reference #226295 for specs and pricing.

A doctoral candidate had the following question regarding the following GaP specs:

Price needed for GaP Wafer undoped (100) or (110) 2"x0.4mm DSP/SSP. Do you know when do people choose semi-insulating or semi-conducting?

Answer:

You use Semi-Insulating wafers when you want them to be very transparent to IR radiation and/or non-conductive to electrical current. You use Semi-Conducting wafers, either n-type or p-type, when you want them to conduct electrical current readily.

So you would use SI GaP wafers as optical windows, piezoelectric devices, substrates for making High Frequency transistors. You would use SC GaP for LED's, Lasers and photo-transistors handling considerable amount of current.

Reference #210755 for specs and pricing.

A postdoc requested a quote for the following:

I want to buy GaP wafers (Undoped, Double side polished, 110-cut, thickness: 0.2 to 0.5 mm, size: any size between 10mmx10mm to 4" in diameter).These GaP wafers will be used for THz field generation and detection. research

Gallium Phosphide wafers, Prime Grade, P/P 2"Ø×450±50μm,

LEC n-type undoped GaP [110]±0.5°, n-type Ro > 5E8 Ohmcm,

Nc < 8E07/cc, u > 160cm2/Vs, EPD<4E4/cm2,

Both-sides-polished,

2 Flats:

Primary flat: 16±2mm @ (1-10),

Secondary flat: 8.0±1.5mm @ (00-1),

Sealed under nitrogen in single wafer cassette,

Note: bubble type defects: present <20μm,

Parameters measured at 300K

Reference #271387 with any question and pricing.

Great for low cost light emitting diodes (LEDs). In addition, the brilliance of the bands is enhanced if the device is viewed through an ultraviolet (UV) light source. Hence, this compound presents great advantages when used for solar cells and energy conversion.

| Item | Qty | Type/Dop | Ori | Dia (mm) | Thck (μm) | Pol | Res Ωcm | Nc a/cm3 | Mobil cm2/Vs | EPD /cm2 |

|---|---|---|---|---|---|---|---|---|---|---|

Undoped Gallium Phosphide |

||||||||||

| 5229 | 10 | undoped | [100] | 2" | 350 | P/P | n-type 0.104 | <4E16 | >141 | <1E5 |

| EJ Flats; Epi Ready | ||||||||||

| G543 | 1 | undoped | [110] ±0.5° | 5×6mm | 400 | P/P | n-type >0.9 | <5E16 | 140 | <4.7E4 |

| Ohmic Contacts on the 0.4x6mm edges | ||||||||||

| 4898 | 2 | undoped | [111B] ±0.5° | 2" | 400 | P/E | n-type 240 | 1.6E14 | 160 | <5E4 |

| EJ Flats, Epi Ready | ||||||||||

N-Type Gallium Phosphide: Sulfer Doped |

||||||||||

| 5161 | 2 | n-type : Sulfer Doped | [100-10° towards[110]] ±1° | 2" | 302 | P/E | 0.115 | 4.75E17 | 115 | <8E4 |

| EJ Flats; Epi Ready | ||||||||||

| 4348 | 1 | n-type: S | [100-6° towards[111]] ±1° | 2" | 400 | P/E | 0.058 | 9.9E17 | 107 | <5.3E4 |

| SEMI Flats; Epi Ready | ||||||||||

| 5170 | 1 | n-type:S | [111A] ±0.5° | 2" | 350 | P/E | 0.043 | 1.8E18 | 81 | <1E5 |

| SEMI Flats; Epi Ready | ||||||||||

P-type Gallium Phosphide : Zinc (Zn) |

||||||||||

| 5034 | 1 | p-type(Zn) | [100] | 2" | 400 | P/E | 0.164 | 5.5E17 | 69 | <5.3E4 |

| SEMI Flats; Epi Ready, Wafers have small edge chips near PF | ||||||||||

| 4324 | 1 | p-type:Zn | [111B] ±0.5° | 2" | 350 | P/E | 0.34 | 2.4E17 | 75 | <5E4 |

| SEMI Flats (PF@[110], SF@[112]), Epi Ready, Wafer unsealed | ||||||||||

Cadmium-Doped Gallium Phosphide |

||||||||||

| 99B | 15 | p-type:Cd | [100] | 2" | 400 | C/C | 2.2 | 2.5E16 | 120 | <8E4 |

| P/E or P/P, SEMI/EJ Flats, to be polished, MOQ=5 wafer | ||||||||||

| 99A | 1 | p-type:Cd | [100] | 2" | 400 | P/E | 2.0 | 2.5E16 | 120 | <8E4 |

| SEMI Flats; Epi Ready, doped with Cadium; More such wafers can be made | ||||||||||

Chromium Doped Gallium Phosphide |

||||||||||

| 178 | 7 | SI :Cr | [100] | 2" | 400 | P/E | 2E10 | 4.1E6 | 75 | <5E4 |

| US Flats; Black spots on surface | ||||||||||

| 219A | 1 | undoped | [100] | 3" | 400 | P/P | n-type 0.21-0.29 | (1.5-2.3)E17 | 128-140 | <2E5 |

| SEMI Flats; Chips at edge | ||||||||||

Scientists have used Gallium Phosphide (GaP) wafers to research photofunctional construct that Interfaces Molecular Cobalt-Based Catalysts for H2 Production to a visible-light-absorbing semiconductor.

Our research client used the following specs. Reference #225200 for pricing.

Single crystalline (100) GaP wafers

were purchased from University Wafer. The wafers were p-type doped

with Zn, yielding a resistivity of 1.17 × 10-1 Ω·cm, a mobility of 77

cm2 V-1 s-1, and a carrier concentration of 6.95 × 1017 cm-3. Extended

defects result in an etch pit density (EPD) of 4.5 × 104 cm-2.

As the name suggests, a light-absorbing semiconductor has an incredibly high refractive index. This property allows it to efficiently convert solar energy into electrical energy. In photovoltaic applications, light beams are reflected off the surface of the semiconductor, which is then converted into electricity. This process is called photovoltaic conversion. As photovoltaic conversion is a key element in photovoltaic technology, it is crucial to know the properties of light-absorbing materials and how to design them to be highly efficient.

The visible-spectrum range is extremely rich in energy. So, having a semiconductor material that can fully exploit this spectrum would be a real boon to the material world. Unfortunately, most of these materials are expensive and contain toxic elements. To overcome these problems, material scientists from Kyushu University and Tokyo Institute of Technology have worked together to develop a new, cheaper and non-toxic narrow-gap semiconductor material with high potential for photofunctional and light-based applications.

Silicon is an example of a light-absorbing semiconductor material. The band gap of this material is about 1.1 eV, or about 1100 nm. This wavelength promotes an electron from the valence band to the conduction one. This wavelength of light is too low for human vision. However, the band gap of this material allows it to absorb much higher-energy wavelengths, which correspond to the energy difference between the valence and conduction bands.

Gallium phosphide is a nonlinear semiconductor with an indirect bandgap that is transparent in visible and long-infrared wavelengths. However, its use as a photonic material in nanophotonic devices has been limited. The reason for this is that gallium phosphide is not very well characterized as an integrated photonic material, and it lacks high-resolution transparency.

The active region of VCSELs is sandwiched between layers of crystals. The gain medium used in 850-nm VCSELs consists of a mixture of gallium and arsenic. In 1,300-nm VCSELs, the gain medium is made of indium phosphide. Although indium phosphide is a strong material for mirrors, it's difficult to build them with this material.

VCSELs are currently being developed by several companies. Lumentum, for example, controls 50% of the global VCSEL market and has sold more than 1 billion VCSELs. Its technology is used in smart phones, industrial sensing, and 3D facial recognition. The company has a long history of volume manufacturing, which has helped it refine its manufacturing process, improve growth quality, and decrease cost. It has installed significant scale-up capacity to meet current demand and has planned expansion to meet future needs.

The disadvantages of gallium phosphide include its high cost, low sensitivity, and thermal instability. But its optical properties make it an ideal material for inexpensive LEDs. Furthermore, it's transparent, which makes it useful in other applications.

Another major advantage of VCSEL production over edge-emitting lasers is that they can be tested at multiple stages of the manufacturing process. In contrast, edge-emitting lasers can't be tested until the final stage, and this means the end result could be inferior if there are poor-quality materials or improper processing. With VCSELs, this testing can be done at several stages and the results can be readily analyzed.

The main disadvantage of conventional VCSELs is that their short wavelengths cause blurring when images are displayed at high data rates and at a distance. To overcome this problem, longer-wavelength VCSELs have been developed. These devices use different substrate wafers than their shorter-wavelength counterparts.

Despite these advantages, there are still significant challenges for long-wavelength VCSELs. Because of the difficulty in manufacturing them, they are not yet widely deployed for subsystem applications. However, these lasers are nearing commercial viability. These devices are ideal for applications requiring optical power, such as in wireless broadband.

Another advantage of VCSELs is their high-power output. This means that they can be used to create symmetrical laser beams for various high-end semiconductor applications. Aside from high-power output and long-term reliability, VCSELs also have low fabrication cost, which increases their appeal.

Photodetectors based on Indium Gallium Arsenide (InGaAs) or Indium Phosphide (InP) wafers are commonly used for SWIR detection. They have several uses, including gas sensing, night vision, and telecommunications.

What is SWIR Detection?

Swinging wave infrared or SWIR detection technology is an effective tool for detecting a wide variety of  objects. This type of technology has applications in both military and civil applications. SWIR cameras provide high contrast images even in challenging atmospheric conditions. They can also detect objects from a distance.

objects. This type of technology has applications in both military and civil applications. SWIR cameras provide high contrast images even in challenging atmospheric conditions. They can also detect objects from a distance.

The use of SWIR can be very effective in detecting military vehicles, submarines, and other targets in far off locations. In the modern era of threats, being able to detect targets at greater distances is crucial. This can be especially true in the remote mountain ranges or far out at sea, where visibility can be very poor, particularly in bad weather. Compared to conventional optics, long-range SWIR technology has a maximum range that is limited only by the magnification of the optics.

The SWIR spectral band provides unique advantages in contrast to other wavelength bands. Researchers have deployed several imagers on aircraft, including the Airborne Visible/Infrared Imaging Spectrometer (AVIRIS), which has a spectral resolution of two to 20 m. Other methods use multispectral satellites with lower spectral resolution. Landsat and AVIRIS are two examples of multispectral satellites that use single-band infrared technology. Although they do not have the highest spectral resolution, these satellites are still effective and embedded in many commercial and military systems.

SWIR detectors use multiple wavelengths to detect a variety of materials. This allows them to differentiate between clouds and snow by examining the spectrum. This method can be used to detect metals and other materials in the atmosphere.

Video: SWIR Detectors for Machine Learning

Gallium phosphide is an excellent material for photonic structures in the visible wavelength range. However, high quality epitaxial growth is required for gallium phosphide to achieve its desirable properties. This limits the choice of substrates and photonic applications. However, a simple process called transfer bonding makes it possible to grow single crystal gallium phosphide thin films with excellent optical properties, including low surface roughness and high room temperature band edge photoluminescence.

The semi-insulating InP mirror wafer is expected to become a mainstream photodiode material for high-speed communications. Such systems are expected to reach a transmission speed of 40 Gbps. In addition, next-generation mobile phones require higher speed and capacity. InP wafers are smaller than GaAs wafers. However, the industry is moving toward the production of four-inch-diameter InP wafers.

Photodetectors using gallium phosphide wafer technology also use InP-based lasers. These lasers emit light at a broad wavelength range and are eye-safe. They are also a great choice for communications. They are highly sensitive to light and can convert this data into digital signals.

Single-beam Z-scan techniques are also useful in estimating the third-order nonlinearities of GaP samples. The setup for this type of experiment is similar to that described elsewhere, with the laser beam focused by a 150-mm plano-convex lens, and the transmitted light recorded by a Thorlabs DCC1545M CMOS camera.

Gallium phosphide (GaP) wafers are typically two-inch-diameter small-area discrete chips. Despite the low price tag, GaP wafers have a high potential yield per wafer. The manufacturing process involves a high temperature and pressure.

Researchers have investigated the ultrafast nonlinear dynamics of crystalline GaP using a pump-probe technique. They found that GaP exhibits modulations of up to 70% in sub-30 fs. This modulation may result from changes in the optical Kerr effect and two-photon absorption. These properties could lead to efficient all-optical signal processing.

Gallium phosphide wafers can be made with an alloy of gallium and indium. The two materials are both Group III semiconductors. A combination of InGaAs and GaAs is used in photodetectors.

The difference in transmissivity between the two types of semiconductors is largely related to the bandgap's spectra. The lower bandgap wavelength, t = 0 fs, leads to a stronger dark current.

Gallium phosphide nanowires can be placed on the surface of the GaP photonic-crystal membrane. These nanowires are about 50 nm wide and 2.5 microm long. They can promote cell adhesion and axonal outgrowth. The nanowires are also capable of improving cell survival. The researchers tested these nanowires on the fruit fly Drosophila melanogaster.

Micro-Raman spectra of individual GaP NWs were obtained using a 514.5 nm excitation source. The spectra showed an asymmetric TO band with a shoulder peak at 360 cm-1. This would be caused by a frequency-dependent damping oscillator, as Bakker had suggested.

Detectors using HgCdTe wafers are popular in the SWIR region, but are expensive and require a complex cooling system. Extended InGaAs detectors have been extensively investigated, but their SWIR performance is limited and they do not cover the entire wavelength range.