Ultra-Thin LiTaO3 Pyroelectric Detectors

A senior scientist requested a quote for the following.

We are looking for ultra thin LT wafers used for pyroelectric detectors.

Are your Lithium Tantalate (LiTaO3) Wafers-Free Standing

Quantity:

We are looking at an equivalent monthly quantity of 500, 2000 and 10000 pc wafers.

Diameter:

2.5” diameter (which is the preferred diameter).

Orientation:

We’d like to keep the option open for the parameters, except that the orientation is z-cut.

Thickness:

Is there a common thickness that you commonly produce? If not, we can explore 30um and 60um thickness.

Would you be able to support me? What is the most cost efficient configuration?

Can you send us a more detailed data-sheet for the LiTaO3 wafer?

Also, what is the capability and capacity to produce this?

Reference #322055 for specs and pricing.

Get Your Quote FAST! Or, Buy Onlineand Start Researching Today!

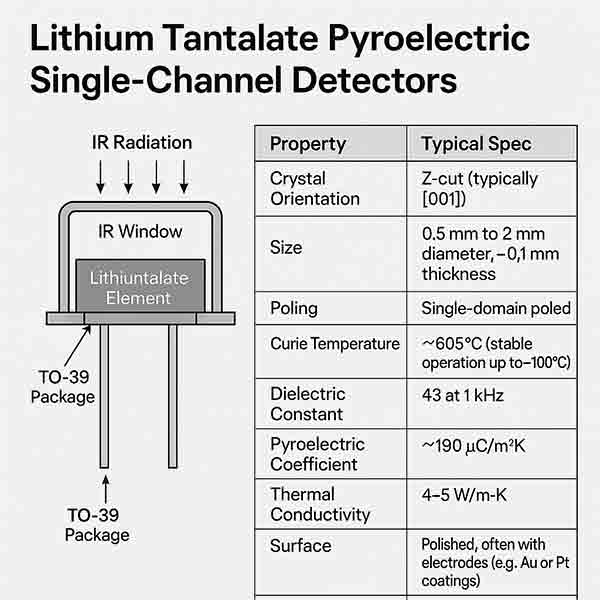

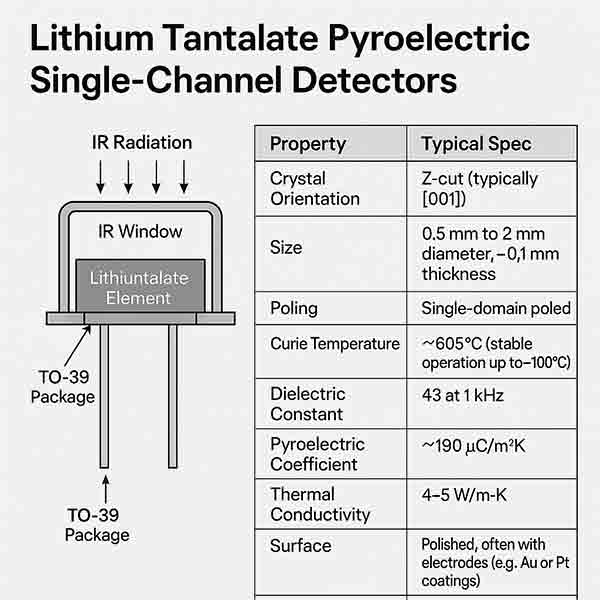

What Are Pyroelectric Detectors?

Pyroelectric detectors convert temperature changes (caused by absorbed IR radiation) into electrical signals due to the pyroelectric effect of LiTaO₃. These are typically housed in TO-39 or TO-5 style metal packages for stability and shielding.

What Are They Used For?

They are used in:

-

Infrared spectroscopy (IR absorption analysis)

-

Gas sensing (e.g., CO₂, CH₄ detection)

-

Flame and fire detection

-

Motion detectors

-

Non-contact temperature measurement

-

FTIR spectrometers

-

IR remote controls

-

Security and surveillance systems

Why Are They Important?

-

High sensitivity to small temperature changes

-

Fast response times

-

Stable over a wide temperature range

-

Compact and cost-effective

-

Broad spectral response in the mid-IR region (2–15 µm)

-

No need for cooling, unlike some photonic IR detectors

They are ideal for portable and battery-powered IR sensing systems.

📐 Common LiTaO₃ Specs for These Detectors

| Property |

Typical Spec |

| Crystal Orientation |

Z-cut (typically [001]) |

| Size |

~0.5 mm to 2 mm diameter, ~0.1 mm thickness |

| Poling |

Single-domain poled |

| Curie Temperature |

~605°C (stable operation up to ~100°C) |

| Dielectric Constant |

~43 at 1 kHz |

| Pyroelectric Coefficient |

~190 µC/m²K |

| Thermal Conductivity |

4–5 W/m·K |

| Surface |

Polished, often with electrodes (e.g., Au or Pt coatings) |

| Resistance |

High electrical resistivity (~10¹⁴ Ω·cm) for low noise |

🧪 Fabrication Notes

-

LiTaO₃ wafers are precision-sliced and polished.

-

Electrodes are deposited (usually in a sandwich configuration).

-

The crystal is then packaged with an IR window (e.g., silicon, polyethylene, or germanium) depending on the spectral range.