Why Metrology Labs Choose Us

We solve the biggest headache in sourcing reference materials: Quantity.

- No Minimums: Buy 1 wafer, not a full cassette of 25.

- Logarithmic Sets: Stock options from 0.001 to >10,000 Ω·cm.

- Consistent Specs: We match thickness and orientation across resistivity bins for accurate variables.

Request a Quote

Tell us your required resistivity targets (e.g., "I need a 4-point probe set: 0.01, 10, and 1000 Ohm-cm").

Build Your Own Calibration Dataset

Target Audience: Metrology Engineers, Lab Managers, and Process Engineers.

If you are calibrating metrology tools—such as 4-point probes, eddy current gauges, or contactless resistivity mappers—you rarely need a full cassette of 25 identical wafers. You need a Reference Set: a collection of single wafers spanning a logarithmic range of resistivities.

UniversityWafer, Inc. solves the "over-ordering" problem. We allow you to purchase single wafers to create a custom reference library that meets your exact linearity requirements, saving your lab budget for other equipment.

Real-World Examples: Calibration Sets

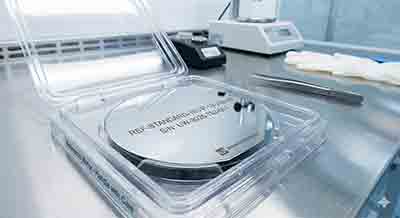

Below are examples of reference specifications we frequently supply to university labs and fab metrology departments. We ensure consistent thickness and orientation across the set so that resistivity is your only variable.

1. The "Logarithmic" 4-Point Probe Set

Designed for verifying tool linearity from conductive to semi-insulating ranges. Our clients use this set to ensure their probes read accurately across orders of magnitude.

| Range Category | Target Resistivity | Wafer Type | Growth Method |

|---|---|---|---|

| Degenerate (Low) | 0.001 – 0.005 Ω·cm | P-Type (Boron) | Czochralski (CZ) |

| Gap Range | 0.1 – 0.5 Ω·cm | P-Type (Boron) | CZ (Tight Sort) |

| Standard Prime | 1 – 10 Ω·cm | P-Type (Boron) | Czochralski (CZ) |

| High Resistivity | > 1,000 Ω·cm | P-Type (Boron) | Float Zone (FZ) |

2. High-Precision Eddy Current Standards

For applications requiring strict thickness control and surface quality.

- Diameter: 100mm, 150mm, or 200mm

- Thickness: 500μm ± 10μm (Tight Tolerance available)

- Orientation: <100> or <111>

- Surface: Single Side Polished (SSP) or Double Side Polished (DSP)

Why "Standard" Wafers Fail at High Resistivity

Many researchers unknowingly order standard CZ wafers hoping for 1,000 Ω·cm resistivity, only to find the results unstable. Standard CZ silicon contains oxygen impurities from the quartz crucible, which limits stable resistivity to ~50-100 Ω·cm.

The Solution: For your high-resistivity (>1,000 Ω·cm) reference point, we supply Float Zone (FZ) silicon. Grown without a crucible, FZ silicon offers the high purity required for accurate high-resistance calibration.

Ready to configure your set?

We have thousands of wafers in stock. Simply fill out the form on the left with your target resistivities, and we will check our inventory for the closest matches.