Order Thin Film Lithium Niobate (TFLN) Substrates

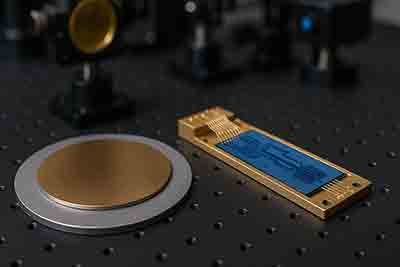

UniversityWafer, Inc. supplies thin film lithium niobate (TFLN/LNOI) substrates for integrated photonics, high-speed electro-optic modulators, nonlinear optics, SAW devices, and quantum photonics. Our wafers offer exceptional surface quality, strong light confinement, and precise film thickness control for advanced research and device development.

Available Thin Film Lithium Niobate Options

- Thin Film LiNbO3 on Insulator (LNOI) – High-confinement films for integrated photonics

- Bulk Lithium Niobate – SSP/DSP polished wafers for waveguides, modulators, and frequency conversion

- MgO-doped LiNbO3 – Reduced photorefractive damage for high-power optical systems

- Custom TFLN Thickness – From ~300 nm to several microns

Common Specifications

- Diameters: 2”, 3”, 4” (custom sizes available)

- Film Thickness: 300 nm – several μm

- Handle Substrates: Si, SiO2/Si, Sapphire, Custom

- Crystal Orientations: X-cut, Z-cut, Y-cut

- Surfaces: SSP, DSP, epi-ready polished

Our TFLN wafers support high-speed modulators, nonlinear optical circuits, microresonators, integrated quantum devices, and hybrid silicon–lithium niobate photonics. Tell us your requirements and we will match the best wafer for your application.

Get a Quote for TFLN Substrates

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

Understanding the Advantages of Thin Film Lithium Niobate

Thin film lithium niobate (TFLN) is reshaping modern photonics and electronics. By taking the well-known electro-optic, nonlinear, and piezoelectric properties of bulk lithium niobate and packing them into films only a few hundred nanometers to a few microns thick, TFLN enables much stronger light confinement, higher bandwidth, and tighter integration than traditional crystal platforms.

Key Insights About Thin Film Lithium Niobate

- TFLN offers 10–100× stronger light confinement than bulk LiNbO₃, enabling highly compact photonic devices.

- Typical film thicknesses range from ~300 nm to several microns, ideal for tightly confined waveguides.

- Applications include high-speed modulators, optical communications, SAW devices, nonlinear optics, quantum photonics, and neuromorphic computing.

- Integrated devices on TFLN can exceed 20–100 GHz bandwidth with significantly lower drive voltages than bulk modulators.

- Hybrid TFLN–silicon platforms allow footprints 50–100× smaller than conventional discrete optical components.

- State-of-the-art TFLN waveguides now routinely achieve losses below 0.1 dB/cm, supporting low-noise, high-efficiency circuits.

Introduction to Lithium Niobate and Its Thin Film Evolution

Lithium niobate (LiNbO₃) has been a workhorse material in photonics for decades, thanks to its strong electro-optic effect, significant second-order nonlinearity, wide transparency window, and robust piezoelectric response. Historically, these advantages were harnessed using bulk crystals and diffused or etched waveguides. While powerful, those early platforms were relatively large, had limited integration density, and required higher drive voltages.

Thin film lithium niobate addresses these limitations. By forming a thin, high-quality LiNbO₃ layer on a suitable substrate, designers can confine light much more tightly, dramatically enhance field intensities, shrink device footprints, and reduce power consumption. This shift from bulk to thin film has triggered a new wave of lithium niobate photonics research and commercial development.

How Thin Film Lithium Niobate Is Fabricated

The performance of TFLN devices depends heavily on how the films are made. Several fabrication routes are used, each with its own trade-offs in terms of crystal quality, cost, and scalability.

Ion Slicing and Smart Cut Technology

One of the most widely used methods for producing high-quality TFLN is ion slicing (often described as Smart Cut technology). In this approach, hydrogen ions are implanted into a bulk LiNbO₃ wafer at carefully chosen energies and doses. The implanted wafer is then bonded to a handle substrate—commonly silicon with a silicon dioxide buffer layer—using surface activation and low-temperature bonding.

A controlled thermal anneal causes a thin LiNbO₃ layer to separate along the implanted region, leaving a high-quality film on the handle wafer. A final chemical-mechanical polishing step brings the surface roughness down to well below a nanometer RMS. This route preserves the excellent bulk crystal properties while enabling wafer-scale thin films suitable for demanding photonic integrated circuits.

Deposition-Based Techniques

Alternative routes to thin film LiNbO₃ include sputtering, pulsed laser deposition, and other thin film deposition methods. These techniques allow composition engineering and multilayer stacks, but often require additional optimization to reach the crystal quality and optical performance achieved with ion-sliced films. As these methods mature, they may become attractive for specialized devices where tailored stoichiometry or complex heterostructures are needed.

Thin Film Lithium Niobate in Optical Communications

TFLN has had a major impact on optical communication systems, where bandwidth, power efficiency, and integration density are critical. The strong electro-optic effect of LiNbO₃, combined with sub-micron waveguide confinement, enables compact, high-speed modulators for datacenters, long-haul links, and coherent communication systems.

High-Speed Electro-Optic Modulators

Electro-optic modulators convert electrical data into optical signals that can travel over fiber. Thin film LiNbO₃ modulators can achieve extremely high bandwidths—well beyond 50–100 GHz—while operating at much lower drive voltages than traditional bulk devices. This combination reduces energy per bit and eases the requirements on the driving electronics.

- Ultra-high bandwidth: Supports next-generation data rates for 400G, 800G, and beyond.

- Lower drive voltages: Reduced Vπ thanks to stronger confinement and optimized electrode geometry.

- Compact footprint: Waveguide and modulator lengths can be shrunk dramatically compared to bulk platforms.

Surface Acoustic Wave and RF Devices

TFLN is also attractive for acoustic devices, building on lithium niobate’s strong piezoelectric properties. When configured appropriately, thin films can support Surface Acoustic Wave (SAW) structures with higher operating frequencies, enhanced coupling, and better opportunities for integration with RF electronics.

These TFLN-based SAW devices can be used in RF filters, resonators, and sensing elements where tight control of frequency response and compact form factors are essential. The reduced film thickness allows higher frequency operation without requiring extremely small electrode features, which helps bridge the gap between RF and photonic circuits on a shared platform.

Nonlinear Optical Devices on TFLN

The strong second-order nonlinear response of LiNbO₃ is amplified by thin film confinement. By guiding light in high-index-contrast TFLN waveguides, the optical intensity within the nonlinear medium increases substantially, boosting conversion efficiencies for a wide range of nonlinear processes.

Frequency Conversion and Parametric Devices

TFLN enables efficient second-harmonic generation, sum- and difference-frequency generation, and optical parametric processes on chip-scale devices. The combination of high χ², low propagation loss, and tight confinement makes it possible to build compact, power-efficient wavelength converters and tunable sources for spectroscopy, sensing, and quantum optics.

Quantum Photonics on Thin Film Lithium Niobate

Quantum photonics leverages single photons and entangled states of light for secure communication, sensing, and quantum information processing. TFLN has emerged as a strong candidate platform because it offers low optical loss, strong nonlinearity, and fast electro-optic control in a geometry compatible with integrated quantum circuits.

On a single TFLN chip, designers can combine photon-pair sources, routing waveguides, interferometers, and phase modulators. This integration potential supports more complex quantum circuits than would be feasible with bulk optics, and helps move quantum technologies toward scalable, manufacturable systems.

Integration with Silicon Photonics

One of the most powerful directions for TFLN is its integration with silicon photonics. Silicon provides mature, CMOS-compatible fabrication and low-loss passive routing, while LiNbO₃ provides strong electro-optic and nonlinear functionality. By bonding TFLN films onto silicon or co-packaging them using heterogeneous integration, designers can build hybrid photonic integrated circuits that combine the strengths of both materials.

Heterogeneous Integration and Hybrid PICs

Several approaches are used to integrate TFLN with silicon, including direct bonding, adhesive layers, and intermediate oxide stacks. These methods must account for differences in thermal expansion and processing conditions, but when optimized they allow high-quality, low-loss interfaces between the platforms.

Hybrid TFLN–silicon photonic integrated circuits support:

- Low-loss passive routing in silicon waveguides.

- High-speed, low-voltage modulation in TFLN sections.

- On-chip nonlinear wavelength conversion and signal processing.

Emerging Applications and Future Directions

The application space for thin film lithium niobate is expanding rapidly. Beyond established roles in communications and RF-photonics, researchers are exploring TFLN for neuromorphic photonic computing, advanced sensing, and large-scale quantum information processing.

In neuromorphic photonics, TFLN devices can implement high-speed, low-energy optical neurons and synapses that process information using light rather than charge. In quantum applications, TFLN’s ability to integrate sources, modulators, and routing elements on a single chip supports increasingly complex quantum circuits with improved stability and scalability.

Overall, thin film lithium niobate represents a major advance over traditional bulk platforms, enabling compact, energy-efficient, and highly integrated devices across telecommunications, RF systems, nonlinear optics, and emerging quantum and neuromorphic technologies.