Order Ultra-Thin Silicon and Flexible Substrates Today

Contact us for pricing, custom thickness options, and availability for silicon, SOI, quartz, glass, GaAs, GaN, and SiC substrates used in flexible electronics research.

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

What Are Flexible Electronics?

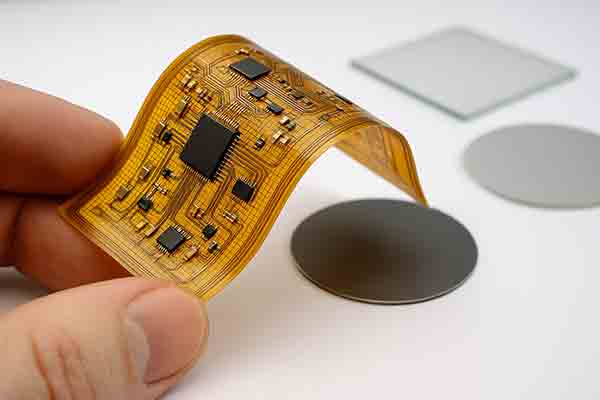

Flexible electronics refer to devices that can bend, fold, stretch, or conform to curved surfaces while maintaining electrical functionality. Instead of relying on rigid printed circuit boards or thick silicon wafers, researchers build flexible devices on thin, mechanically compliant substrates such as polyimide, PET, PEN, PDMS, thin glass, or ultra-thin silicon. This field enables new device architectures where electronics can follow the shape of the human body, aircraft fuselage, medical implants, textiles, or any non-flat surface.

The key advantage of flexible electronics is that they preserve electronic performance while allowing mechanical freedom. This combination supports innovations in wearable health systems, soft robotics, flexible displays, conformal antennas, biomedical implants, environmental sensors, energy harvesting devices, and next-generation human–machine interfaces.

How Flexible Devices Are Fabricated

Most flexible electronics begin on either a flexible polymer film or a rigid substrate that is later thinned or transferred to a flexible carrier. When researchers fabricate directly on polyimide, PET, or PEN, they typically laminate the film onto a silicon or glass carrier wafer to perform thin-film deposition, lithography, and etching. After processing, the polymer is released from the carrier, creating a fully flexible device. This approach is common in printed electronics, flexible sensors, and low-temperature thin-film transistors.

For high-performance applications, the opposite strategy is often used: devices are first fabricated on a crystalline silicon wafer, and then the active layers are transferred onto a flexible substrate. This can be accomplished by thinning the entire wafer to tens of microns, etching a sacrificial layer in SOI structures, or creating detachable device islands that are printed onto polyimide, elastomers, or thin glass. This method allows researchers to combine the electrical performance of silicon with the mechanical flexibility of polymers and stretchable substrates.

Why Substrates Matter in Flexible Electronics

The choice of substrate determines nearly every property of a flexible or stretchable device, including its minimum bending radius, thermal processing limits, mechanical durability, transparency, dielectric behavior, and compatibility with deposition and patterning steps. Polyimide is favored for its high-temperature stability and toughness; PET and PEN are used for low-cost transparent devices; PDMS is essential for stretchable systems; and ultra-thin glass provides superior optical quality and barrier protection. Crystalline materials such as silicon, quartz, sapphire, GaAs, GaN, and SiC are used when flexible systems require high-performance electronics, RF components, optical devices, or power modules.

When these rigid materials are thinned or transferred, they offer a unique combination of flexibility and exceptional electrical behavior. For example, ultra-thin silicon can bend while supporting CMOS circuits; quartz improves RF performance in conformal antennas; and sapphire and GaN enable flexible high-brightness micro-LED displays or high-frequency amplifiers. This blending of flexible substrates and traditional semiconductor materials allows researchers to build devices that would not be possible with polymers alone.

Applications Enabled by Flexible Electronics

Flexible electronics enable a wide range of advanced technologies. Wearable biomedical patches use polyimide and ultra-thin silicon to monitor heart rate, hydration, and metabolic signals. Foldable and rollable displays rely on flexible glass and transparent conductive films to create thin, light, and durable user interfaces. Soft robotic skins employ PDMS and transferred silicon membranes to sense pressure, strain, and motion. Conformal aerospace and automotive antennas use GaAs, GaN, and high-resistivity silicon to deliver high-frequency communication and sensing performance on curved surfaces. Even implantable neural probes and biomedical stimulators benefit from ultra-thin silicon and polymer stacks that safely contour to organic tissue.

By combining the right substrate with the appropriate fabrication strategy, researchers can create devices that bend, stretch, withstand repeated deformation, and still deliver reliable electronic behavior. As flexible electronics continue to expand across industries, the availability of high-quality substrates—from polymers to thin silicon, quartz, glass, sapphire, GaN, and SiC—remains essential to pushing performance, reliability, and design freedom forward.

Flexible Electronics Substrates from UniversityWafer, Inc.

UniversityWafer, Inc. supplies research-grade substrates that help engineers move from rigid prototypes to bendable, conformal, and wearable flexible electronics. We support academic labs, startups, and industrial R&D groups with small-lot orders, custom thicknesses, and fast quotes on ultra-thin silicon, glass, quartz, and compound semiconductor wafers used in flexible and hybrid-flex devices.

Ultra-Thin and Standard Silicon Wafers for Flexible Devices

Crystalline silicon remains the workhorse material for high-performance electronics, even when the final device must bend or conform to a curved surface. Researchers typically fabricate devices on standard silicon wafers and then thin or transfer them to flexible carriers.

UniversityWafer, Inc. offers:

- Prime silicon wafers from 2” up to 300 mm for device fabrication before thinning or transfer.

- Custom thickness options suitable for backside grinding, etching, or direct thinning into bendable silicon substrates.

- High-resistivity silicon wafers for flexible RF, sensor, and analog circuit development.

- Silicon orientations such as <100> and <111> for process compatibility and mechanical reliability.

Researchers use these wafers to create ultra-thin silicon membranes, device islands, and flexible CMOS, which can then be laminated onto polyimide, PET, or elastomer substrates.

Learn more about our silicon inventory: Silicon Wafers.

Examples of Flexible Electronics and the Substrates Behind Them

Flexible electronics appear across multiple emerging technologies, each relying on carefully selected substrates to balance mechanical flexibility and device performance. Wearable biomedical sensors and skin-mounted health monitors typically use polyimide or ultra-thin silicon laminated on soft elastomers to achieve high sensitivity while bending with the body. Flexible OLED displays and e-paper panels use thin glass or PEN substrates with deposited transparent electrodes. Conformal antennas for aerospace, satellites, and unmanned systems often integrate GaAs or GaN devices thinned and bonded onto polyimide sheets. Stretchable robotics and electronic skin combine PDMS with transferred silicon membranes or microstructured metal traces to retain performance under repeated deformation. In each case, substrates such as silicon, quartz, glass, sapphire, GaAs, GaN, and SiC supplied by UniversityWafer, Inc. form the foundation of the device’s electrical, mechanical, and thermal behavior while enabling true flexibility or stretchability.

SOI Wafers and Membrane-Friendly Structures

Silicon-on-insulator (SOI) wafers are a powerful starting point for flexible electronics because the buried oxide simplifies the release of thin active layers. After fabrication, researchers can undercut or etch sacrificial regions and transfer the thin device layer to a flexible polymer substrate.

UniversityWafer, Inc. can provide:

- SOI wafers with tailored device layer thicknesses for thin-film electronics and flexible CMOS research.

- High-quality buried oxide layers to support membrane release and transfer printing processes.

- Research quantities for process development and early-stage prototyping.

Glass, Quartz, and Sapphire for Flexible-Hybrid Stacks

Flexible and hybrid-flex systems often combine polymers with thin glass or crystalline substrates to improve barrier properties, optical performance, and dimensional stability. Ultra-thin glass and quartz wafers can bend while still providing excellent surface quality for thin-film deposition.

UniversityWafer, Inc. offers:

- Borosilicate and fused silica wafers used as thin, flexible glass carriers or barrier layers in displays and sensors.

- Quartz wafers for high-frequency and RF components that may be integrated into conformal antennas and sensor arrays.

- Sapphire wafers for optoelectronic devices and micro-LEDs that can later be assembled into flexible modules.

Explore related substrates:

Compound Semiconductor Wafers for Flexible RF and Power Electronics

Many flexible and conformal systems require high-frequency or high-power components that are still built on compound semiconductors and later thinned or integrated into flexible packages. These devices can be bonded to polyimide or other carriers after wafer thinning.

UniversityWafer, Inc. can support flexible RF and power research with:

- GaAs wafers for high-speed RF and microwave circuits that can be assembled onto flexible interposers.

- GaN-on-sapphire and GaN-on-SiC wafers for high-power, high-frequency amplifiers integrated into conformal systems.

- SiC wafers for power conversion stages used in aerospace, automotive, and energy applications where weight and form factor are critical.

Related product pages include:

- Gallium Arsenide (GaAs) Wafers

- Gallium Nitride on Sapphire (GaN) Wafers

- Silicon Carbide (SiC) Wafers

Carrier and Release Substrates for Polymer-Based Flexible Electronics

Many flexible electronic process flows start on rigid carriers and end on soft polymers. Silicon, glass, and quartz wafers are often used as carriers for spin-coated polyimide, PDMS, or other elastomer layers, enabling standard lithography and deposition steps before release.

UniversityWafer, Inc. helps researchers by supplying:

- Thermally oxidized silicon wafers that serve as controlled release layers for thin membranes and flexible devices.

- Double-side polished silicon and glass wafers with excellent flatness for coating, patterning, and subsequent delamination.

- Custom thickness and surface finish options to match specific flexible process requirements.

Why Flexible Electronics Researchers Choose UniversityWafer, Inc.

- Research-friendly quantities: Order a single wafer, a small lot, or scale up as your flexible device process matures.

- Custom specifications: Diameter, orientation, resistivity, dopant type, and thickness can be matched to your fabrication flow.

- Diverse material portfolio: Silicon, SOI, quartz, glass, sapphire, GaAs, GaN, SiC, and more, from one source.

- Fast response: Quick quotes and support to keep experimental timelines on track.

Tell us about your flexible electronics project, and we will recommend substrates that fit your process temperature, mechanical flexibility, and device performance requirements.