Order Lithium Tantalate (LiTaO3) Wafers for RF, Optical, and Sensor Applications

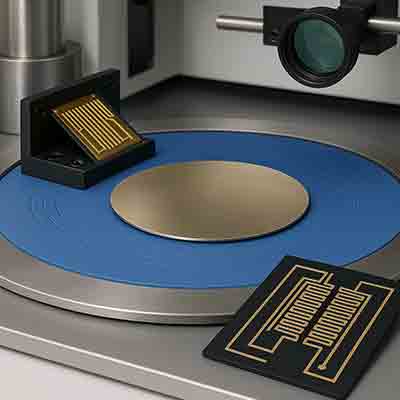

UniversityWafer, Inc. supplies high-quality lithium tantalate (LiTaO3) wafers for SAW devices, RF filters, optical modulators, nonlinear optics, pyroelectric detectors, and advanced acoustic sensors. Our wafers offer excellent piezoelectric, pyroelectric, and electro-optic performance with tight tolerances for demanding applications.

Available Lithium Tantalate Options

- 36° Y-cut LiTaO3 – Popular for SAW filters and RF front-end modules

- 42° Y-cut LiTaO3 – Improved temperature stability for RF and sensing

- Z-cut LiTaO3 – Ideal for electro-optic and pyroelectric applications

- Undoped & Doped Grades – For optical, RF, and sensing environments

Common Specifications

- Diameters: 2”, 3”, 4” (other sizes available)

- Surfaces: SSP, DSP, epi-ready polished

- Low-defect crystal quality for RF and optical performance

- Custom orientations and tolerances available

Our lithium tantalate wafers serve key applications including SAW filters, RF resonators, optical modulators, pyroelectric infrared detectors, nonlinear frequency converters, and acoustic sensors for industrial and scientific use. Share your device requirements and we will match the correct wafer cut, thickness, and specification.

Get Your LiTaO3 Wafer Quote FAST! Or, Buy Online and Start Researching Today!

Introduction to Lithium Tantalate Wafers

Lithium tantalate (LiTaO3) is a multifunctional crystal that combines strong piezoelectric, electro-optic, and pyroelectric properties in a single material. These capabilities make LiTaO3 wafers a core platform for telecommunications, photonics, and sensing technologies where precise control of acoustic waves, light, or temperature is required. The crystal structure, in which lithium and tantalum ions occupy ordered positions within an oxygen framework, gives rise to ferroelectric behavior and a high Curie temperature of about 610 °C, enabling stable device operation across wide temperature ranges.

At the wafer level, lithium tantalate can be prepared with excellent surface quality, tight orientation control, and application-specific cuts. These features allow engineers to design reliable SAW filters, optical modulators, nonlinear converters, and high-sensitivity sensors on the same materials platform.

Telecommunications: SAW Filters and RF Devices

One of the most important uses of lithium tantalate wafers is in Surface Acoustic Wave (SAW) devices for RF filtering. SAW filters rely on the piezoelectric coupling of LiTaO3 to convert electrical signals into acoustic waves that travel along the wafer surface. The waves are shaped, delayed, or filtered before being converted back into electrical form.

LiTaO3-based SAW filters offer several advantages for wireless communication systems:

- High quality factor (Q): Enables sharp passbands and strong rejection of nearby channels.

- Compact size: Allows complex ladder or duplexer filters to fit inside small mobile modules.

- Low insertion loss: Reduces power consumption and improves signal integrity.

- Temperature stability: Specific crystal cuts minimize frequency drift in commercial and industrial environments.

Modern smartphones, base stations, and IoT devices often contain dozens of lithium tantalate SAW filters operating from sub-GHz cellular bands to multi-GHz Wi-Fi and GPS frequencies.

Optical Applications of Lithium Tantalate

Electro-Optic Modulators

The strong electro-optic (Pockels) effect in LiTaO3 makes it a powerful material for optical modulators. When an electric field is applied to a lithium tantalate waveguide or bulk crystal, the refractive index changes, allowing modulation of intensity, phase, or polarization in fiber-optic communication systems.

Key advantages include:

- High modulation bandwidth: Supports tens of gigabits per second.

- Low drive voltage: Enables efficient phase modulation with minimal electrical power.

- Low optical loss: Transparent over telecom wavelengths and resistant to photorefractive damage.

- Thermal robustness: Maintains stable behavior over wide temperature ranges.

Nonlinear Optical Frequency Conversion

Lithium tantalate exhibits strong second-order nonlinear optical behavior, enabling frequency doubling and sum-frequency generation. Periodically poled lithium tantalate (PPLT) achieves quasi-phase matching, greatly improving conversion efficiency for generating new laser wavelengths.

Compact frequency converters based on PPLT are widely used in spectroscopy, quantum optics, medical lasers, and precision metrology.

Sensing and Detection Using Lithium Tantalate

Pyroelectric Sensors and Thermal Imaging

The pyroelectric effect in LiTaO3—its ability to generate an electric charge when heated or cooled—makes it ideal for thermal and infrared sensing. Pyroelectric detectors built on LiTaO3 are used in passive infrared (PIR) motion sensors, thermal imaging systems, and non-contact temperature measurement.

Benefits include:

- High pyroelectric coefficient: Enables high sensitivity to small temperature changes.

- Fast response: Thin-film structures support rapid detection times.

- Wide operating range: Functions from cryogenic to high temperatures.

- Low noise: Suitable for precision IR detection when paired with low-noise amplifiers.

Acoustic Wave Sensors

LiTaO3 wafers enable SAW and BAW sensors for detecting pressure, temperature, chemical species, and biological markers. Changes in surface mass or environmental conditions alter acoustic wave velocity or attenuation, providing measurable outputs.

Because these sensors can operate wirelessly and withstand harsh environments, they are used in automotive systems, industrial monitoring, and remote sensing applications.

Future Directions

The versatility of lithium tantalate wafers is driving new research in photonics, quantum technologies, RF systems, and sensor platforms. As devices move toward higher frequencies and smaller footprints, LiTaO3’s combined piezoelectric, electro-optic, and pyroelectric performance will remain essential.

Advances in domain engineering, thin-film processing, and hybrid integration with silicon and other photonic materials are expanding what is possible with lithium tantalate. These developments will continue to position LiTaO3 wafers as a key enabling material for next-generation optical, RF, and sensing technologies.