Silicon Wafers are Key Components in Modern Light-Based Technologies

These thin slices of crystalline silicon are used in everything from solar cells to advanced optical sensors. Let's explore how to choose the right silicon wafers for light-based applications, looking at their important role in photonics and optoelectronics.

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

![]()

Key Takeaways for Choosing Silicon Wafers in Light-Based Technologies

- Wafer thickness impacts device flexibility and performance

- Surface finish quality is critical for precise light manipulation

- Doping type and level influence electrical and optical properties

- Crystal orientation affects light interaction and device efficiency

- Purity grade is essential for high-performance optical applications

- Specialized wafers like SOI and GaN-on-Si offer unique advantages

- Matching wafer characteristics to specific light applications is crucial

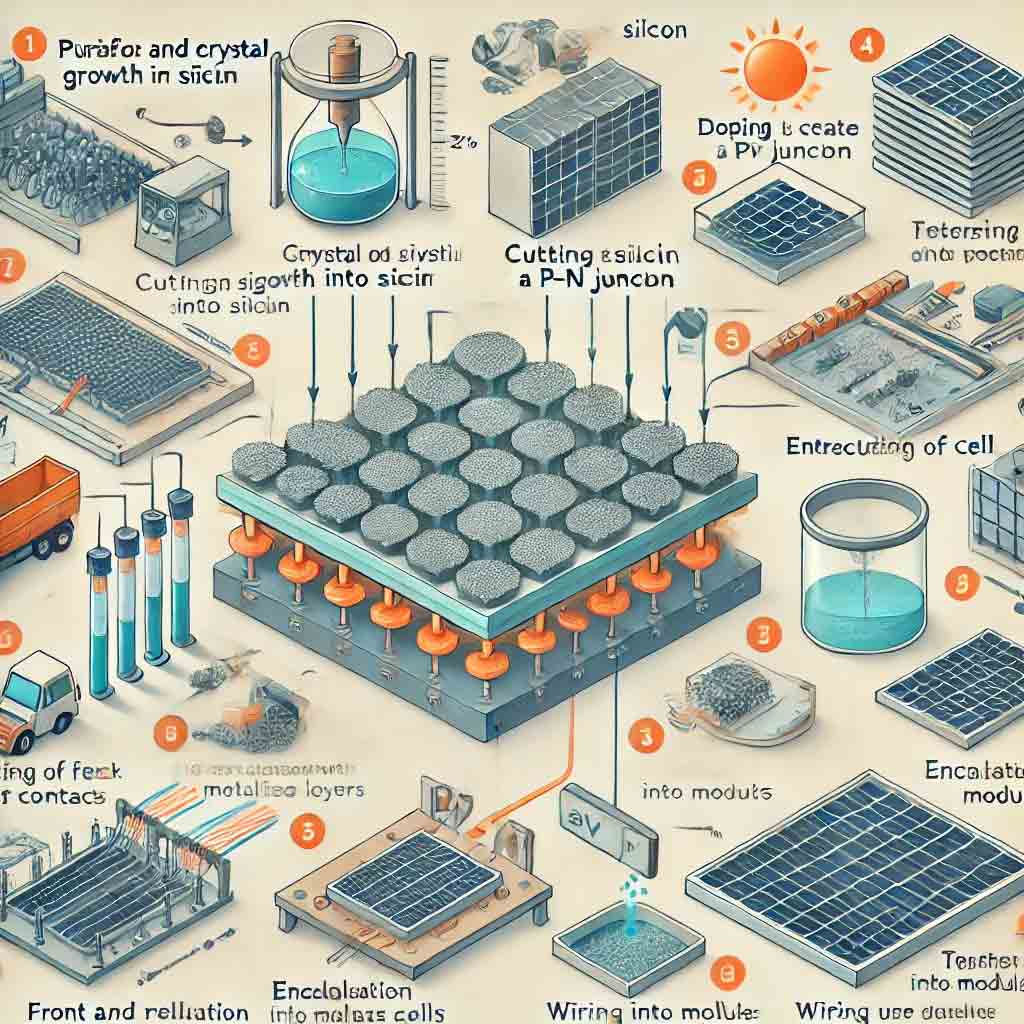

Understanding Silicon Wafer Basics

Silicon wafers are thin discs cut from a single crystal of silicon. They're incredibly pure, containing 99.9999999% silicon. This purity is important for consistent electrical and optical properties across the wafer, which is crucial for high-performance light-based applications. Wafers come in different sizes, from small 2-inch discs for research to large 12-inch (300mm) plates for high-volume manufacturing. Choosing the right size affects production yield and manufacturing costs.

In light-based tech, silicon wafers are like blank canvases ready to become amazing devices. They can be engineered to create solar cells that capture sunlight or sensitive optical sensors that detect very faint light signals. Silicon wafers are versatile because of their unique atomic structure and the ability to control their electrical and optical properties through various processes. To get the most out of them, it's important to pick the right type of wafer for your specific light-based project, considering things like how the wafer absorbs, emits, or manipulates light.

Picking the Perfect Wafer: What to Look For

Choosing the right silicon wafer isn't simple. You need to think about several important factors. Each wafer characteristic can greatly affect how well the final light-based device works, how efficient it is, and how reliable it is. Let's look closer at these important aspects:

1. Wafer Thickness

Thickness is really important in light-based technologies. It affects the wafer's physical and optical properties. Thinner wafers, usually 100 to 200 micrometers thick, are more flexible and work well for things like bendable solar cells or flexible displays. They let more light through and can help reduce material costs. Thicker wafers, from 500 to 1000 micrometers, are stronger and often better for things like tough optical sensors or powerful photonic devices. Picking the right thickness means balancing things like how much light the wafer absorbs, how strong it needs to be, and how well it needs to handle heat for your specific use.

2. Surface Finish

How smooth a wafer's surface is really matters for light-based applications. Even tiny bumps can mess up how the device works. A rough surface can scatter light in unwanted ways, making optical devices less efficient and adding noise to sensitive detectors. For high-precision things like advanced LEDs, laser diodes, or integrated photonic circuits, wafers need to have a super smooth, mirror-like finish. These surfaces, often made by a process called chemical-mechanical polishing (CMP), can be as smooth as a few atoms thick. The quality of the surface finish directly affects how well layers can be added on top and how good the final optical device will be.

3. Doping Type and Level

Doping is adding specific impurities to the silicon to change its electrical and optical properties. This is important for making the wafer work well for different light-based applications. There are two main types of doping:

- N-type: These wafers have extra electrons added, usually using phosphorus. They're good for certain types of solar cells because they move electrons better and don't degrade as much in light.

- P-type: These have fewer electrons (or more "holes"), usually made by adding boron. They're used in many light applications, including regular solar cells and many types of light detectors.

How much dopant is added (the doping level) is also important. More dopants make the wafer conduct electricity better, which can be good for some uses. But for devices that need to be sensitive to light, like light detectors or high-efficiency solar cells, less doping is often better. The best doping type and level depend on what you're using the wafer for, balancing things like how well charges move, how much light it absorbs, and its electrical resistance.

4. Crystal Orientation

Silicon crystals have different atomic arrangements along different planes, kind of like the faces of a cut diamond. How these planes are oriented, labeled with numbers like (100), (110), and (111), affects how light and electrical charges interact with the wafer. Each orientation has its own advantages:

- (100) orientation: Often used in CMOS technology, this orientation is good for moving electrons and is popular for integrated photonic circuits.

- (110) orientation: This is better for moving "holes" (the absence of electrons), which can be good for certain types of light detectors and light-emitting devices.

- (111) orientation: Known for trapping light well, making it a great choice for solar cells and other devices that need to absorb a lot of light.

The crystal orientation you choose can affect how well the device absorbs light, how charges move through it, and even how easy it is to process the wafer further. Understanding these orientations is key to making your light-based devices work as well as possible.

5. Purity Grade

For most light-based technologies, having really pure silicon wafers is super important. Even tiny amounts of impurities can change how the wafer behaves electrically and optically, which could make the device not work as well. High-purity wafers, usually 99.9999999% (9N) silicon, are essential for sensitive optical devices and high-efficiency solar cells. These super-pure wafers help reduce unwanted effects, lower optical losses, and make sure the wafer works consistently across its whole surface.

The purity grade directly affects important things like how long minority carriers (the less common type of charge carrier) last, which is crucial for turning light into electricity efficiently in solar cells. For cutting-edge uses in quantum optics or ultra-sensitive light detectors, even purer wafers might be needed. When picking wafers for your light-based project, think about not just what you need now, but also what you might need in the future as your technology gets better.

Special Wafers for Light-Based Tech

As light-based technologies get more advanced, sometimes regular silicon wafers aren't enough to meet the tough requirements of new applications. This has led to the development of special types of wafers designed to overcome specific limitations and make light-based devices work even better:

Silicon-on-Insulator (SOI) Wafers

SOI wafers are a big step forward in wafer technology. They have a special layered structure: a thin layer of high-quality silicon (called the device layer) separated from the main silicon base by a buried layer of insulating material, usually silicon dioxide. This "sandwich" structure offers several benefits for light-based applications:

- Better light confinement: The insulating layer stops light from escaping into the base. This is really useful in integrated photonic circuits, where keeping light in specific paths is crucial.

- Improved electrical isolation: The insulating layer reduces unwanted electrical effects, allowing optoelectronic devices to work faster and more efficiently.

- Better heat management: The buried oxide layer can help spread out heat more effectively, which is important for high-power optical devices.

- Less light loss: SOI wafers allow for the creation of high-contrast optical waveguides, which means light travels through them with less loss in photonic circuits.

SOI wafers are being used more and more in advanced photonic integrated circuits, fast optical modulators, and next-generation silicon photonics applications. Their unique structure allows for the creation of super-efficient optical devices that don't waste light or electricity, leading the way for more compact and powerful light-based technologies.

Gallium Nitride on Silicon (GaN-on-Si)

While silicon is great for many light-based applications, it has limits when it comes to certain high-power or short-wavelength light-emitting devices. This is where gallium nitride (GaN) comes in. GaN-on-Si wafers combine the great light-emitting properties of GaN with the cost-effectiveness and large-scale manufacturing abilities of silicon substrates. Here's why GaN-on-Si is becoming more important:

- High-brightness LEDs: GaN can emit light in the blue and ultraviolet range, which is crucial for making white LEDs and other bright lighting solutions.

- Power efficiency: GaN-based devices can work at higher voltages and temperatures than regular silicon, making them ideal for high-power lasers and power electronics in optical systems.

- Cost-effective production: By growing GaN on large silicon wafers, manufacturers can use existing silicon processing equipment, which makes production much cheaper compared to using pure GaN substrates.

- Better heat management: The silicon base helps spread out heat better, which is crucial for high-power optical devices.

GaN-on-Si technology is changing the fields of solid-state lighting, high-frequency electronics, and power conversion devices used with optical systems. It's enabling the development of more efficient, brighter, and more compact light-emitting devices for a wide range of uses, from advanced display technologies to next-generation laser systems.

Choosing Wafers for Different Light Applications

Now that we've looked at the basic characteristics of silicon wafers and some special types, let's see how to pick the best wafers for specific light-based technologies. Choosing the right wafer can really affect how well your optical devices work, how efficient they are, and how reliable they are:

Solar Cells

For solar cells, the main goal is to absorb as much light as possible and turn it into electrical energy efficiently. When picking wafers for solar applications, think about:

- Thickness: Medium thickness (around 180-200 micrometers) is a good balance between absorbing light and not using too much material. Thinner wafers can use less silicon but might need special care during manufacturing.

- Surface texture: A textured surface, often made by chemical etching, can really reduce light reflection and increase absorption. Look for wafers with surfaces specially designed for solar applications.

- Doping: Both N-type and P-type wafers are used in solar cells, depending on the design. N-type wafers are becoming more popular because they don't degrade as much in light.

- Crystal orientation: (100) orientation is common, but (111) can trap light better in some cell designs.

- Purity: High purity (at least 6N) is crucial to make the cell as efficient as possible by reducing losses.

Also consider wafers specially made for solar applications, like those with built-in structures to trap light or advanced surface treatments.

LEDs and Lasers

Light-emitting devices need wafers that can handle high electrical currents and produce bright, efficient light. Key things to consider include:

- Substrate type: While traditional LEDs use various III-V semiconductors, silicon-based LEDs (especially micro-LEDs) are becoming more common. For these, think about SOI wafers or special silicon wafers with optimized doping.

- Thickness: Thinner wafers (100-150 micrometers) are often better for managing heat, which is crucial for high-power LEDs and lasers.

- Surface quality: Ultra-smooth surfaces are essential for even light emission and reducing light losses. Look for wafers with very low surface roughness (< 1 nm RMS).

- Doping: Precise control of doping is crucial. The type and amount of doping will depend on the specific LED or laser design.

- Crystal quality: High crystal quality with few defects is essential for efficient light emission. Consider wafers with low etch pit density (EPD) values.

For high-power or short-wavelength applications, GaN-on-Si wafers offer big advantages, combining the excellent light-emitting properties of GaN with the cost-effectiveness of silicon substrates.

Optical Sensors

Optical sensors need to be very sensitive to changes in light while minimizing noise. When picking wafers for sensor applications, focus on:

- Surface finish: Ultra-smooth surfaces are critical to minimize noise and enhance sensitivity. Look for wafers with surface roughness less than a nanometer.

- Doping: Low doping levels are generally preferred to increase sensitivity. The specific level will depend on the sensor type and what wavelength of light it's detecting.

- Crystal orientation: (100) orientation is common, but (111) might be better for certain types of photodetectors because of its electronic properties.

- Thickness: The best thickness depends on the wavelength of light being detected. Thinner wafers might be better for near-infrared sensors, while thicker ones could be better for longer wavelengths.

- Purity: High purity (9N or higher) is crucial to reduce unwanted currents and improve the signal-to-noise ratio.

Consider specialized wafers like SOI for better performance in certain sensor applications, especially where electrical isolation is important.

Photonic Devices

Advanced light-manipulating devices, such as photonic integrated circuits, need wafers with precise optical properties. Key considerations include:

- Wafer type: SOI wafers are often the best choice for photonic devices because they're great at containing light.

- Device layer thickness: Precise control of the top silicon layer thickness is crucial for working with specific wavelengths. Typical thicknesses range from 220 nm to 500 nm, depending on the application.

- Buried oxide (BOX) layer: For SOI wafers, the thickness and quality of the buried oxide layer are critical for optical isolation.

- Surface roughness: Ultra-smooth surfaces (< 0.2 nm RMS) are essential for low-loss light transmission in waveguides.

- Uniformity: High thickness uniformity across the wafer is crucial for consistent device performance.

- Doping: Custom doping profiles may be needed for active photonic devices like modulators or detectors integrated into the photonic circuit.

For cutting-edge photonic applications, consider wafers with special coatings or structures designed to enhance specific optical properties or enable new functionalities.

Conclusion: Lighting the Way with the Right Wafers

Choosing the right silicon wafer is crucial for success in light-based technologies. The journey from a raw silicon disc to a sophisticated optical device is complex and requires understanding how each wafer characteristic affects the final product's performance. By carefully considering factors like thickness, surface finish, doping, crystal orientation, and purity grade, engineers and researchers can select the perfect wafer for their specific application.

Whether you're improving solar energy efficiency, developing new LEDs, creating sensitive optical sensors, or pioneering integrated photonics, the choice of silicon wafer plays a key role. Each application needs a unique combination of wafer properties to work best.

The world of silicon wafers is always changing. New technologies like ultra-thin wafers, 3D-structured substrates, and hybrid materials are expanding what's possible with silicon in light-based applications. These advancements aren't just small improvements; they're opening doors to entirely new types of devices and applications that were once thought impossible.

In this fast-changing field, it's important to stay informed about the latest developments in wafer technology. Continuous learning and working with experts can provide valuable insights, helping you make smart decisions that can greatly impact the success of your light-based projects.

Remember, choosing a silicon wafer isn't just a technical decision; it's a strategic one that can define what your final product can do, how well it performs, and even if it's commercially viable. By carefully selecting the right silicon foundation, you're not just building a device; you're paving the way for innovations that could reshape industries, advance scientific understanding, and ultimately, illuminate new technological frontiers.