Choosing the Correct Orientation

Not all wafer orientations are created equal. Whether you need <100> for standard CMOS fabrication or <110> for precise MEMS vertical walls, UniversityWafer, Inc. stocks all standard and custom crystal axes. We help you find the right flat and notch orientations to get your project running immediately.

We stock every major crystal orientation:

- ✅ <100>: Standard for ICs & Logic (Easily Cleaved)

- ✅ <111>: High Pack Density & Anisotropic Etching

- ✅ <110>: Ideal for Optical & MEMS Structures

- ✅ Custom: <211>, <510>, and Off-Axis Cuts

Request a Quote

Select Your Orientation

- (100) Silicon Wafers: Industry Standard for MOS.

- (111) Silicon Wafers: For Anisotropic Etching.

- (110) Silicon Wafers: For MEMS & Optical.

- (211) & (510) Orientations: Custom Research Cuts.

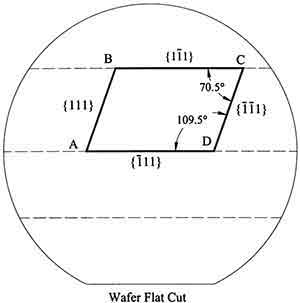

- Wafer Flats Guide: Identify your wafer instantly.

Shop by Application

Select the right crystal lattice for your process:

- CMOS / Logic: <100> (Low interface state density).

- Wet Etching (KOH): <100> creates pyramids; <110> creates vertical walls.

- Cleaving / Dicing: <100> cleaves easily at 90° angles.

- Power Devices: <111> often used for high-power bipolar devices.

Real-World Scenarios: Solving Orientation Challenges

Case Study 1: The "Lost Datasheet" Problem

Researcher: "I bought silicon wafers but lost the specification sheet. How can I determine the orientation without expensive X-ray equipment?"

UniversityWafer Solution: You can use the "Hammer Test" (destructive).

If you strike the wafer center:

<100> Wafers: Will split into four equal, clean parts (90° cleavage planes).

<111> Wafers: Will shatter into triangular shards or many uneven pieces.

Case Study 2: Etching Vertical Walls

MEMS Engineer: "I need to etch deep vertical trenches with KOH wet etching. My current <100> wafers are creating V-shaped grooves."

Recommendation: Switch to <110> Silicon Wafers. In <110> silicon, the {111} planes are perpendicular to the surface, allowing you to etch straight vertical walls, unlike the 54.7° slope found in <100> wafers.

What is Silicon Wafer Orientation?

Orientation is defined by the Miller Index, with (100) or (111) faces being the most common for silicon. The orientation determines the wafer's  properties when measured in different directions (anisotropic). Silicon wafers are thin slices of semiconducting material widely used in the production of electronics and micromechanical devices.

properties when measured in different directions (anisotropic). Silicon wafers are thin slices of semiconducting material widely used in the production of electronics and micromechanical devices.

Silicon wafers are grown as large crystal boules using the Czochralski method. The crystal growth of the melt corresponds to this initial orientation until the last large single crystal acquires a known crystal orientation. During manufacturing, the silicon is cut into wafers aligned with specific crystal planes. This alignment influences electronic properties, ion implantation depth, and how the wafer cleaves (breaks).

Video: Breaking Silicon to Determine Orientation

How to Choose a Silicon Orientation?

Choosing between flat, diamond, planar, and membrane silicon wafers is essential in semiconductor processing. The orientation of silicon wafers is important because of the way that the silicon wafers interact with each other. A thin stripe, also known as a "flat", can prevent heat from penetrating the silicon surface. This feature makes non-silicon wafers a popular choice for applications requiring high temperatures.

Heat Dissipation & Thermal Properties

The silicon wafer orientations have an impact on heat dissipation. Non-silicon alloys have a black stripe along the surface that prevents heat from conduction through flat surfaces. This prevents heat from permeating the surface and is redirected towards the interior of the component. Because of this advantage, these types of semiconductors are preferred in applications involving extreme temperatures.

Another important consideration when selecting silicon wafer orientations is heat dissipation. For example, a flat wafer is more likely to resist heat than a non-silicon one. It is crucial in applications where it is required to function at extreme temperatures. This makes the silicon wafer an excellent choice for temperature-sensitive components. However, it can also lead to defects. Therefore, it is important to choose the right substrates for the application you are developing.

Common Orientations Explained

(100) Orientation: The Industry Standard

(100) is the most common orientation for MOSFETs and Integrated Circuits (ICs).

Why? It has a lower interface state density compared to (111), which improves the performance of the gate oxide in transistors. (100) oriented silicon wafers are more efficient for making integrated circuits (IC).

Cleaving: (100) wafers usually break along the {110} planes, which meet the surface at 90 degrees. This makes them easy to dice into square chips.

(111) Orientation: High Density & Power

(111) has a higher atomic density on the surface.

Why? It is often used for bipolar transistors and power devices due to its electrical properties. It is also easier to oxidize than (100). The (111) orientation is easier to cleve than the (100) orientation (specifically for triangular patterns).

Cleaving: (111) wafers are harder to cleave into squares because the cleavage planes meet at non-90 degree angles, leading to triangular fragmentation.

(110) Orientation: MEMS & Optical

They report that they have found that this orientation is mainly used to produce MEMS structures, but not for other types of silicon wafer orientation. If 110 silicon wafers are produced according to the present invention, the single crystal silicon ingots, which have a flat alignment, are disposed of by conventional wire saws with a tilting mechanism. Instead of producing a 110 silicon wafer, they can be cut with a diameter of 300mm using the Czochralski method.

Video: Difference Between (100), (110), and (111)

How to Determine a Silicon Wafer's Crystal Orientation

Below is an image of what happens to two wafers when a hammer hits a nail at the wafer's center. On the left are (100) oriented silicon. When struck the wafer split into four equal parts. If you then do the same to the pieces, those pieces will also split into four pieces. (100) oriented silicon wafers are more efficient for making integrated circuits (IC).

The wafer on the right are (111). That wafer shatters into many different pieces. Thus this is an easy way to find out the orientation of your silicon wafer cassette.

![]()

The orientation of the silicon happens during the silicon wafer manufacturing process while the silicon is in the crystal boule. We aslo have wafer notch orientation specs on notched substrates.

Note: Wafers smaller than 200mm usually use flats. Wafers 200mm (8 inch) and larger typically use a single small notch.

Standard Wafer Flat Dimensions

| Spec | 2" | 3" | 100mm | 125mm | 150mm | 200mm | 300mm |

|---|---|---|---|---|---|---|---|

| Diameter | 2.000" ± 0.015" (50.8 ± 0.38mm) |

3.000" ± 0.025" (76.2 ± 0.63mm) |

100 ± 0.5mm | 125 ± 0.5mm | 150 ± 0.2mm | 200 ± 0.2mm | 300 ± 0.2mm |

| Thickness | 279 ± 25 μm (0.011") |

381 ± 25 μm (0.015") |

525 ± 20 μm | 625 ± 20 μm | 675 ± 20 μm (or 625 μm) |

725 ± 20 μm | 775 ± 20 μm |

| Primary Flat Length | 15.88 ± 1.65mm (0.625") |

22.22 ± 3.17mm (0.875") |

32.5 ± 2.5mm | 42.5 ± 2.5mm | 57.5 ± 2.5mm | Notch | Notch |

| Secondary Flat Length | 8.0 ± 1.65mm (0.315") |

11.18 ± 1.52mm (0.44") |

18.0 ± 2.0mm | 27.5 ± 2.5mm | 37.5 ± 2.5mm | N/A | N/A |

| Primary Flat Location | {110} ± 1° | {110} ± 1° | {110} ± 1° | {110} ± 1° | {110} ± 1° | {110} ± 1° | {110} ± 1° |

*Values are standard estimates. Always check your specific batch COA.

X-Ray Diffraction

The basic process of producing a silicon wafer is based on an X-ray diffraction method. A diffraction pattern is a picture of a crystal with a specified crystal orientation. In the case of silicon, the X-ray pattern is the best means for verifying the crystal orientation during the machining process. An X-ray diffraction system allows you to achieve a standard accuracy of 0.5 degrees.