Introduction to Advanced Material Dicing

Dicing is a crucial step in semiconductor manufacturing where wafers are cut into individual dies or chips. As technology advances, the materials used in semiconductor production have become more complex, requiring innovative dicing techniques. Traditional methods that worked well for basic silicon wafers now face challenges with advanced materials like compound semiconductors, sapphire, and silicon carbide.

Dicing Calculator - Find out how many pieces you can dice from a certain diameter!

The semiconductor industry continues to push boundaries with smaller feature sizes, thinner wafers, and more complex device architectures. This evolution demands dicing techniques that maintain precision, quality, and efficiency across diverse materials. At University Wafer, we provide specialized dicing services tailored to these advanced materials and their unique properties.

Whether you're working with standard silicon wafers or exploring cutting-edge materials for specialized applications, the dicing process significantly impacts device performance, yield, and reliability. This guide explores the latest innovations in wafer dicing technology, focusing on techniques specifically designed for advanced materials.

Get Your Quote FAST! Or, Buy Online and Start Your Research Today!

Key Takeaways: Advanced Material Dicing Techniques

- Material Versatility: Modern dicing techniques must accommodate diverse materials ranging from traditional silicon to compound semiconductors, sapphire, and silicon carbide, each requiring specialized approaches.

- Technology Evolution: Dicing has progressed from purely mechanical methods to sophisticated laser, plasma, and hybrid techniques that minimize damage while maximizing precision.

- Yield Optimization: Advanced dicing techniques can increase die yield by up to 15% for brittle materials like GaAs and SiC by reducing edge chipping and cracking.

- Process Integration: Innovative approaches like Dicing Before Grinding (DBG) and hybrid dicing sequences are reshaping traditional manufacturing flows for ultra-thin wafers.

- Quality Control: Cutting-edge inspection technologies including acoustic microscopy and 3D profilometry ensure diced components meet increasingly stringent requirements.

- Application-Specific Solutions: MEMS devices, power electronics, and optoelectronic components each require tailored dicing approaches to preserve their unique structures and functionality.

- Economic Considerations: The optimal dicing technique balances precision requirements with production volume, throughput needs, and overall manufacturing costs.

Source: UniversityWafer, Inc.

Fundamental Dicing Technologies for Advanced Materials

Mechanical Blade Dicing

Mechanical blade dicing remains one of the most widely used techniques in the semiconductor industry. This process uses diamond-coated blades to physically cut through wafer materials. While traditional in nature, significant innovations have improved this technique for advanced material applications.

Modern blade dicing systems now incorporate precision-engineered diamond blades with optimized particle sizes and concentrations for specific materials. For example, specialized blade compositions are available for hard materials like sapphire and silicon carbide, which require different cutting parameters than standard silicon. Our silicon pellets are processed using these advanced techniques to ensure high-quality results.

Key advancements in mechanical blade dicing include ultra-thin blade technology (down to 10μm width) for minimizing kerf loss, specialized blade compositions for different material hardness levels, advanced cooling systems to prevent thermal damage, and optimized spindle speeds for different materials. Despite these improvements, mechanical dicing faces challenges with extremely brittle materials or complex multilayer structures where chipping and delamination can occur.

Laser Dicing Technologies

Laser dicing has emerged as a powerful alternative to mechanical methods, particularly for advanced materials and complex device structures. This non-contact technique uses focused laser energy to cut through substrate materials through various mechanisms depending on the laser type and process parameters.

Several laser dicing approaches have been developed for specialized applications:

- Ablation Laser Dicing: Uses short-wavelength lasers (typically UV) to remove material through direct vaporization

- Stealth Dicing: Employs a laser focused within the substrate to create internal structural modifications, followed by mechanical separation

- Water-Jet Guided Laser: Combines laser energy with a water jet that guides the beam and simultaneously cools the cutting area

- Femtosecond Laser Dicing: Utilizes ultra-short pulse durations to minimize heat transfer to surrounding material

Laser dicing offers significant advantages for materials like gallium arsenide, indium phosphide, and glass substrates, where mechanical methods may cause excessive chipping or cracking. The non-contact nature of laser dicing also makes it suitable for extremely thin wafers (below 50μm) that might flex or break under mechanical stress. Our wafer fabrication services utilize these advanced laser techniques when appropriate for the material and application.

Plasma Dicing Innovation

Plasma dicing represents one of the most significant innovations for advanced semiconductor materials in recent years. This technique uses reactive ion etching (RIE) to selectively remove material along predefined streets or scribe lines, creating a chemical rather than mechanical separation process.

The plasma dicing process typically involves applying a protective mask that leaves only the dicing streets exposed, exposing the wafer to a reactive plasma (typically fluorine-based for silicon), chemical etching of the exposed material, and removal of the mask and separation of the dies. This method is particularly valuable for MEMS devices, power semiconductors, and advanced packaging applications where die strength and edge quality are critical.

Plasma dicing offers several compelling advantages for advanced materials, including near-vertical sidewalls with minimal chipping or cracking, no mechanical stress on the wafer, ability to create complex die shapes beyond straight lines, reduction in street width (allowing more dies per wafer), elimination of silicon dust contamination, and excellent compatibility with thin wafers. Our semiconductor processing services include plasma dicing options for customers working with specialized materials and applications requiring the highest precision and quality.

Comparison of Advanced Silicon Wafer Dicing Techniques

- Mechanical Blade Dicing: Cost-effective and versatile but may cause chipping in brittle materials. Typically uses diamond blades with thickness ranging from 0.00075" to 0.500" depending on application requirements.

- Laser Ablation Dicing: Non-contact method offering high precision and ideal for thin wafers. For 100-μm thick silicon, cutting speeds of 350-400 mm/s are achievable with optimized laser parameters.

- Stealth Laser Dicing: Creates internal modification with minimal surface damage, making it excellent for sensitive devices and reducing thermal effects.

- Plasma Dicing: Chemical process creating near-vertical sidewalls with minimal chipping or cracking. Allows for complex die shapes, reduced street width, and eliminates silicon dust contamination. Particularly ideal for MEMS devices and advanced packaging applications.

- Water-Jet Guided Laser: Combines precision of laser cutting with cooling benefits of water, significantly reducing thermal effects during the dicing process.

- Typical Die Street Width: Approximately 75 micrometers (0.003 inches) wide, though precision cuts as small as 25 microns are possible with modern technology.

- Silicon Wafer Thickness: Typically ranges from ultra-thin (50μm) to thick (10mm) for various dicing applications, with thinner wafers increasingly used in 3D packaging.

- Yield Factors: Kerf width (material lost during cutting, typically 50-100 μm), edge exclusion zone, alignment marks, and wafer notch/flat features all impact final yield.

- Mounting Methods: Wafers are typically mounted on dicing tape with a sticky backing that holds the wafer on a thin metal frame during cutting. UV-curable tape is preferred for smaller dies.

- Feed Rate Impact: The speed at which the wafer substrate is fed into the cutting blade significantly impacts yield, productivity, and edge chipping likelihood.

- Dicing Process Selection: Choice depends on material properties, chip size and geometry, precision requirements, production costs, and environmental considerations.

- Quality Control Methods: Include Automated Optical Inspection (AOI), Scanning Acoustic Microscopy (SAM), in-line metrology, die strength testing, and Statistical Process Control (SPC).

Source: UniversityWafer, Inc.

Material-Specific Dicing Approaches

Silicon Wafer Dicing Optimization

Silicon remains the foundation of the semiconductor industry, but even this well-established material continues to present dicing challenges as wafers become thinner and device structures more complex. Modern silicon dicing techniques must balance speed, precision, and damage minimization. For standard silicon wafers, mechanical dicing with specialized diamond blades remains cost-effective, but several innovations have improved the process.

Advanced techniques for silicon include Dicing Before Grinding (DBG), which partially cuts the wafer from the front side, followed by backside grinding to separate the dies, reducing edge chipping. Another approach combines predicing with laser grooving, creating an initial shallow cut with a blade followed by laser processing to complete the separation. Silicon wafer surface roughness must be carefully controlled to ensure clean cuts with minimal chipping. Our polished silicon wafers provide the optimal surface finish for high-precision dicing applications.

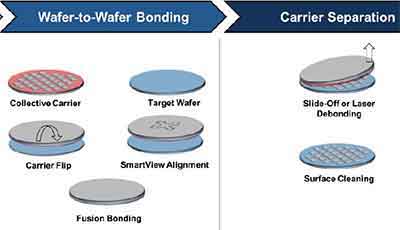

For ultra-thin silicon wafers (below 100μm), a combination of temporary bonding to carrier wafers and specialized dicing techniques is often required. This approach provides mechanical support during processing while enabling the creation of extremely thin dies for advanced packaging applications. Our wafer bonding services support these advanced processing requirements.

Compound Semiconductor Dicing Techniques

Compound semiconductors like gallium arsenide (GaAs), gallium nitride (GaN), and indium phosphide (InP) present unique dicing challenges due to their brittleness and tendency to chip or crack. These materials are essential for high-frequency electronics, optoelectronics, and power devices, making high-quality dicing crucial.

For these materials, specialized approaches include Stealth Dicing (particularly effective for GaAs and InP), controlled depth blade dicing (partial cutting followed by controlled breaking along crystallographic planes), pulsed laser dicing (using ultra-short pulses to minimize heat-affected zones), and hybrid approaches that combine laser pre-cutting with mechanical or chemical separation.

The proper choice of dicing technique depends not only on the base material but also on the specific device structure, layer composition, and intended application. For example, laser devices built on GaAs substrates may require different dicing parameters than RF devices on the same material. Our expertise in wafer fabrication processes enables us to recommend and implement the optimal dicing solution for your specific compound semiconductor application.

Sapphire and Hard Material Dicing Solutions

Sapphire substrates, widely used in LED manufacturing, present some of the most challenging dicing requirements due to their extreme hardness (Mohs hardness of 9). Similar challenges exist with silicon carbide (SiC) and other hard materials used in power electronics and specialized applications.

Advanced techniques for these materials include laser ablation with specialized wavelengths (typically using UV or green lasers optimized for these materials), thermal stress dicing (utilizing controlled thermal gradients to create separation along defined paths), ultra-thin resin blade technology (special blade compositions designed specifically for hard materials), and multi-step processes that combine laser scribing with mechanical breaking or chemical enhancement.

For sapphire substrates in particular, the crystallographic orientation plays a significant role in dicing quality. Cuts aligned with certain crystal planes may produce cleaner edges with less chipping. This consideration must be incorporated into the wafer layout and dicing plan. The helium beam interaction with silicon represents another frontier in advanced material processing, potentially offering new approaches for precision dicing of ultra-hard materials with minimal damage.

Process Optimization for Advanced Dicing

Substrate Preparation and Mounting Techniques

Proper substrate preparation is critical for successful dicing of advanced materials. The mounting process directly impacts dicing quality, yield, and the ability to handle increasingly thin and fragile wafers. Key innovations in substrate preparation include advanced dicing tapes with UV-releasable properties that provide strong support during cutting but allow easy die removal, temporary bonding using sacrificial carrier wafers to support ultra-thin substrates during processing, optimized frame systems that maintain tape tension while minimizing stress, and specialized pre-dicing cleaning processes to remove contaminants that could affect cut quality.

For temperature-sensitive materials, thermal management during mounting becomes crucial. Specialized low-temperature adhesives and mounting systems have been developed to accommodate materials that might degrade or delaminate under standard mounting conditions. Our silicon wafer products are manufactured with precise specifications to ensure compatibility with advanced mounting and dicing processes.

The choice of mounting method depends on the specific material properties, wafer thickness, and dicing technique being used. For example, ultra-thin wafers often require temporary bonding to rigid carriers, while standard thickness wafers may use conventional dicing tape. Our technical team can help you determine the optimal mounting approach for your specific application.

Cutting Parameters and Process Control

Achieving optimal dicing results requires precise control over numerous process parameters, which vary significantly depending on the material and dicing technology used. Modern dicing systems incorporate advanced sensing and feedback mechanisms to maintain process consistency. Critical parameters include blade rotation speed (typically 30,000-60,000 RPM for mechanical dicing), feed rate (the speed at which the blade or laser moves across the wafer), cutting depth (particularly important for partial cutting techniques), coolant flow and composition (critical for heat management and debris removal), and laser power, pulse duration, and frequency (key parameters for all laser-based methods).

Advanced process control systems now incorporate real-time monitoring of these parameters, with automated adjustments to maintain optimal cutting conditions. Machine learning algorithms are increasingly being applied to predict optimal parameters based on material characteristics and desired outcomes. For plasma dicing, critical control factors include gas composition, chamber pressure, RF power, and mask design. These parameters must be precisely tuned for each material type to achieve clean, vertical sidewalls without undercutting or residual damage.

At University Wafer, our dicing processes are optimized for each specific material and application, ensuring consistent, high-quality results. Our experienced technicians continuously monitor and adjust process parameters to maintain optimal cutting conditions throughout the dicing process.

Quality Control and Inspection Innovations

As device dimensions shrink and applications become more demanding, quality control for diced wafers has evolved significantly. Advanced inspection techniques ensure that diced dies meet increasingly stringent requirements for edge quality, dimensional accuracy, and absence of subsurface damage. Modern inspection technologies include Automated Optical Inspection (AOI) with high-resolution imaging systems that identify visual defects like chipping, cracking, or incomplete cuts, acoustic microscopy for non-destructive evaluation of subsurface features and defects, 3D profilometry for precise measurement of cut depth, width, and sidewall angles, X-ray inspection for evaluation of internal structures and hidden defects, and edge roughness analysis for quantitative assessment of die edge quality.

These inspection technologies are increasingly integrated directly into dicing systems, allowing for real-time quality monitoring and immediate process adjustments. This integration is particularly valuable for high-value substrates and critical applications where rework is difficult or impossible. For research applications, we provide detailed surface roughness specifications for our silicon wafers, ensuring that you have the precise material characteristics needed for your dicing process development.

Our quality control processes include both in-process monitoring and post-dicing inspection to ensure that every die meets our strict quality standards. We can provide detailed inspection reports upon request, documenting key quality metrics for your diced wafers or components.

Hybrid and Emerging Dicing Technologies

Multi-Step Dicing Processes

As materials and device structures become more complex, single-method dicing approaches often prove insufficient. This has led to the development of multi-step or hybrid dicing processes that combine the advantages of different techniques. Common hybrid approaches include laser pre-cutting followed by mechanical separation (using laser to create a precise initial cut followed by controlled mechanical breaking), partial blade cut combined with laser completion (combining the speed of blade dicing with the precision of laser processing), plasma dicing followed by mechanical singulation (using plasma to etch most of the material followed by a clean mechanical separation), and chemical-assisted mechanical dicing (enhancing traditional blade dicing with chemical processes that soften or prepare the cut path).

These hybrid approaches are particularly valuable for complex multilayer structures where different materials within the stack respond better to different dicing methods. For example, a silicon-on-insulator (SOI) wafer might benefit from plasma dicing for the silicon layers combined with laser processing for the insulator. Our wafer bonding expertise enables the creation of complex multilayer structures that can be processed using these advanced hybrid dicing techniques.

The development of these hybrid approaches reflects the increasing complexity of semiconductor devices and the need for dicing solutions that can handle multiple materials and structures in a single process flow. By combining the strengths of different dicing methods, these hybrid approaches offer improved quality, yield, and efficiency for advanced semiconductor manufacturing.

Dicing Before Grinding and Other Process Integrations

Traditional semiconductor processing flows typically place dicing near the end of the manufacturing sequence. However, innovative process integrations are reordering these steps to improve quality and yield, particularly for advanced materials and ultra-thin wafers. Significant innovations include Dicing Before Grinding (DBG), which creates partial cuts from the front side of the wafer, followed by backside grinding to complete the separation and achieve the desired thickness, Grinding Before Dicing (GBD), which thins the wafer first, then performs dicing on a temporary carrier, Dicing Before Metallization, which performs dicing prior to certain backend processes to avoid damage to sensitive metal layers, and Pre-Dicing, which creates partial cuts that are completed after subsequent processing steps.

These integrated approaches address the fundamental challenges of handling increasingly thin wafers while maintaining die strength and edge quality. They also enable more efficient processing flows by combining steps that traditionally required separate equipment and handling. The choice of process integration depends heavily on the specific material properties, device structure, and final application requirements. Our team can help you determine the optimal process sequence for your advanced material dicing needs.

For applications requiring ultra-thin dies, such as advanced packaging or flexible electronics, these integrated approaches can provide significant advantages in terms of yield, quality, and cost. Our silicon wafer products are compatible with these advanced processing techniques, ensuring optimal results for your specific application.

Application-Specific Dicing Solutions

MEMS and Sensor Device Dicing Requirements

Microelectromechanical systems (MEMS) and sensor devices present unique dicing challenges due to their fragile moving structures, cavities, and often complex material stacks. These devices require specialized dicing approaches to preserve their functionality and reliability. Key considerations for MEMS dicing include protection of movable structures (preventing damage to delicate mechanical elements during cutting), cavity preservation (maintaining sealed cavities without contamination from dicing debris), material compatibility (addressing the diverse materials often found in MEMS stacks), and release timing (coordinating when mechanical structures are released relative to the dicing process).

Innovative solutions include temporary cavity filling with protective polymers that are later removed, specialized dicing tape systems designed for MEMS devices, and process sequences that perform dicing before final release steps. For pressure sensors, accelerometers, and other devices with exposed membranes, non-contact dicing methods like laser or plasma processing often prove superior to mechanical approaches. These techniques minimize vibration and mechanical stress that could damage sensitive structures.

Our wafer fabrication capabilities support the creation of specialized MEMS structures that can be integrated with appropriate dicing solutions for your specific application. We work closely with MEMS device manufacturers to develop customized dicing processes that preserve device functionality while maintaining high yield and throughput.

Power Electronics and Wide Bandgap Material Processing

Power electronic devices based on wide bandgap materials like silicon carbide (SiC) and gallium nitride (GaN) require specialized dicing approaches due to their hardness, thermal properties, and the critical importance of edge quality for high-voltage operation. Specific challenges and solutions include thick substrate handling (power devices often use thicker substrates that require modified dicing parameters), edge termination preservation (maintaining carefully designed edge structures that prevent premature breakdown), heat management (addressing the high thermal conductivity of materials like SiC during cutting), and surface damage minimization (preventing microscopic cracks that could propagate during device operation).

Advanced techniques for these materials include stepped cutting processes that use progressively finer blade grits, specialized laser wavelengths optimized for wide bandgap materials, and plasma processes tuned for their unique chemical properties. The sidewall quality of diced power devices directly impacts their voltage handling capability and reliability. Therefore, post-dicing treatments like sidewall passivation or edge smoothing are often integrated into the manufacturing process for these specialized components.

Our experience with advanced materials like silicon-carbon composites provides a strong foundation for processing wide bandgap materials for power electronic applications. We can help you develop a dicing process that maintains the electrical performance and reliability of your power devices.

Conclusion

Innovative dicing techniques for advanced materials represent a critical enabler for the continued evolution of semiconductor technology, microelectronics, photonics, and numerous other high-tech fields. As device architectures become more complex and materials more diverse, the importance of specialized dicing approaches will only increase. The optimal dicing solution depends on a complex interplay of factors including material properties, device structure, quality requirements, production volume, and economic considerations.

At University Wafer, we provide both the high-quality materials needed for advanced applications and the expertise to help you select and implement the most appropriate dicing techniques for your specific requirements. From standard silicon wafers to specialized compound semiconductors and emerging materials, our team can support your research, development, and production needs.

For more information about our products and services, please contact our technical team. We welcome the opportunity to discuss your specific requirements and help you navigate the complex landscape of advanced material dicing technologies.