Accelerate Your Aerospace Research

Bring your hybrid-electric and MEMS concepts to life with precision-engineered silicon substrates from UniversityWafer, Inc. Order small quantities, test advanced coatings, and optimize device efficiency for next-generation aircraft systems.

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

Get Your Aerospace Substrates Fast

Researchers and engineers working on hybrid-electric propulsion, MEMS sensors, and SiC power systems rely on UniversityWafer, Inc. for precision substrates that support each stage of development—from concept to prototype and testing.

- Request a Custom Quote for aerospace-grade silicon wafers and specialty substrates.

- Browse Silicon Substrates in stock or order custom specifications.

- Contact Technical Support to discuss doping, orientation, and oxide/nitride coatings for your application.

Recommended Materials for Aerospace Research

- Silicon Carbide (SiC) Wafers – for power conversion and hybrid propulsion drives.

- SOI Wafers – ideal for MEMS devices, isolation circuits, and control systems.

- Thermal Oxide Wafers – for dielectric layers and thermal management testing.

- Quartz Substrates – for optical, thermal, and RF-related aerospace experiments.

Fast Turnaround for Research Projects

UniversityWafer supports aerospace institutions and startups by offering low minimum order quantities and rapid delivery options worldwide. Whether you are testing new SiC-on-Si structures, MEMS accelerometers, or thermal coatings, our substrates help you validate your designs faster.

Get Your Quote FAST!

Order online or email sales@universitywafer.com

Trusted by Researchers Worldwide

UniversityWafer has supplied wafers and substrates to organizations engaged in aerospace, defense, and materials research. Our commitment to quality and consistency ensures that every wafer supports the performance and precision your research demands.

How UniversityWafer’s Silicon Substrates Help Aerospace Researchers Build More Efficient Devices

Aerospace innovation increasingly depends on the ability to design lighter, more efficient, and thermally robust electronic systems. As the industry moves toward hybrid-electric and fully electric aircraft, research teams require precise materials capable of performing reliably in extreme environments. Recent breakthroughs in silicon carbide (SiC) power electronics have demonstrated dramatic improvements in weight and power density for aircraft propulsion drives, as highlighted by Interesting Engineering. Yet behind every SiC and GaN device lies the foundational silicon substrate—the platform that supports sensor integration, control electronics, and system testing during every stage of aerospace R&D.

Why Silicon Substrates Remain Essential

While wide-bandgap materials like SiC and GaN dominate the conversation in high-voltage power systems, silicon substrates remain indispensable for supporting devices that handle signal processing, thermal regulation, and monitoring. Aerospace engineers rely on silicon’s mechanical stability, electrical uniformity, and surface quality to fabricate test circuits, MEMS sensors, and integrated control modules.

- Thermal management research: Silicon wafers are used to evaluate heat dissipation and interface bonding in high-temperature environments.

- Control and sensing: MEMS and CMOS-based devices fabricated on silicon handle vibration, acceleration, and pressure sensing within aircraft modules.

- System reliability: Silicon substrates provide consistent performance under mechanical stress, making them ideal for early-stage aerospace prototypes.

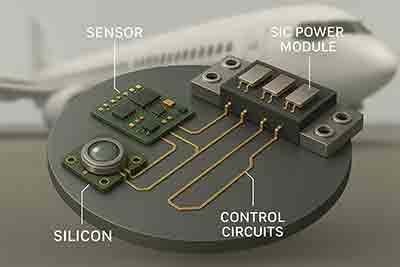

Supporting the Transition to Wide-Bandgap Devices

The next generation of aircraft propulsion depends on integrating SiC power modules with silicon-based support electronics. In this hybrid architecture, silicon substrates are used to fabricate gate drivers, monitoring circuits, temperature sensors, and protection layers that ensure SiC transistors perform efficiently and safely. Researchers use silicon wafers for:

- Testing bonding strength between Si and SiC components during module integration.

- Developing hybrid SiC-on-Si test structures that simulate real aerospace operating conditions.

- Benchmarking thermal cycling performance before full system deployment.

UniversityWafer’s broad selection of silicon substrates allows research groups to fine-tune parameters such as resistivity, orientation, and doping type—variables that directly influence conductivity, junction temperature tolerance, and mechanical strength.

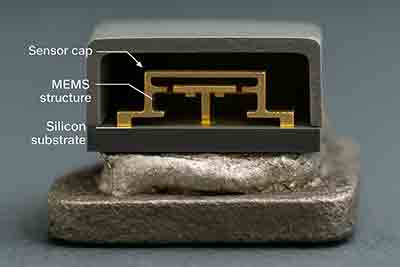

Enabling Reliable MEMS and Sensor Research

Beyond propulsion, the aerospace industry relies on a network of MEMS-based devices to measure pressure, acceleration, and temperature within aircraft. Silicon’s material properties—low defect density, high mechanical stiffness, and compatibility with oxide and nitride layers—make it the preferred substrate for these miniature sensors.

UniversityWafer provides double-side polished silicon wafers and oxide-coated substrates ideal for fabricating high-precision MEMS components. Such substrates are critical in the development of systems used for:

- Flight control feedback sensors and inertial navigation systems.

- Thermal monitoring within hybrid-electric propulsion drives.

- Micro-vibration and shock monitoring for structural integrity testing.

By enabling MEMS and SiC research on complementary silicon platforms, UniversityWafer bridges the gap between laboratory innovation and field-ready aerospace solutions.

Material Specifications for Aerospace Applications

UniversityWafer’s silicon wafers are available in diameters from 25 mm to 300 mm with custom doping (P-type or N-type), thickness, and surface finish options. Aerospace researchers frequently request:

- Orientation: <100> or <111> crystalline structures for MEMS patterning.

- Thickness: From 200 μm to 1 mm, depending on vibration tolerance and stiffness requirements.

- Resistivity: 1–10 Ω·cm for control circuits, lower for thermal interface research.

- Surface finish: Single- or double-side polished with optional oxide or nitride coatings.

Future Outlook

The aerospace sector is rapidly adopting electric and hybrid propulsion technologies that require multi-material semiconductor integration. As this transformation accelerates, silicon will continue to serve as the platform that unites electronic, photonic, and thermal components. UniversityWafer’s focus on flexibility—offering both small-quantity prototype runs and custom material specifications—positions it as a key partner for aerospace research teams worldwide.

From the laboratory to the skies, UniversityWafer’s silicon substrates are enabling the innovation necessary for safer, lighter, and more efficient aircraft.

Reference

Sinha, Sujita (Nov 4, 2025). New silicon-powered electric motor cuts hybrid plane weight, helps them fly farther. Interesting Engineering. Read the article.