What is Vertical Gallium Nitride?

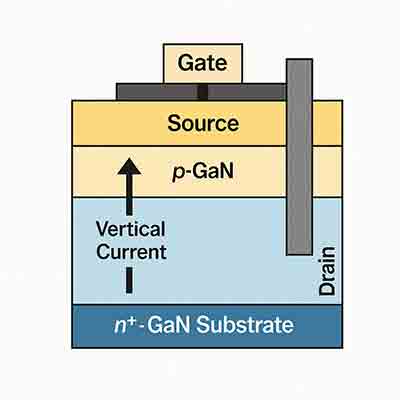

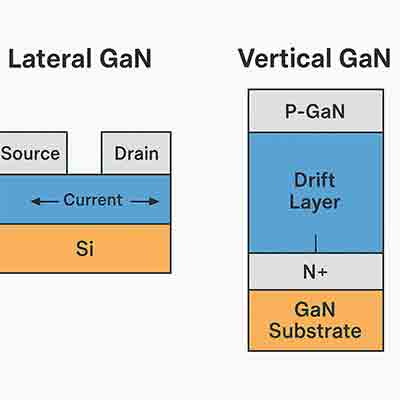

Vertical Gallium Nitride (vertical GaN) refers to a class of power semiconductor devices where current flows vertically—from the top surface of the wafer down to the substrate—rather than laterally across the surface. This architecture leverages GaN’s exceptional material properties (wide bandgap, high breakdown field, high electron mobility) to achieve much higher voltage, current, and power performance than conventional lateral GaN HEMTs.

Request Vertical GaN Wafers

We supply bulk GaN substrates, vertical MOSFET epitaxy, Schottky diode stacks, and custom drift-layer structures optimized for your voltage, current, and efficiency requirements.

Get Your Vertical GaN Wafer Quote FAST! Or, Buy Online and Start Researching Today!

FAQs

Is Vertical GaN available commercially?

Yes — small-volume research wafers and limited production wafers exist.

Does Vertical GaN require GaN-on-GaN structures?

Yes — the device must conduct vertically through GaN.

Can Vertical GaN outperform SiC MOSFETs?

In many cases, especially above 1 kV and at high switching frequencies.

What makes Vertical GaN different?

It conducts current vertically through a GaN drift region, enabling high voltage and low resistance.

Is Vertical GaN replacing SiC?

Vertical GaN competes with SiC in the 1.2–3.3 kV range and often offers faster switching and lower capacitance.

What substrates does Vertical GaN require?

Bulk GaN substrates with extremely low dislocation density.

What applications use Vertical GaN?

EVs, datacenter power, renewable energy inverters, industrial drives, and grid infrastructure.

What Is Vertical Gallium Nitride?

Vertical Gallium Nitride (Vertical GaN) represents the next generation of wide-bandgap power devices. Unlike lateral GaN structures grown on Si or SiC—where current flows across the wafer surface—Vertical GaN devices conduct through the thickness of the GaN substrate.

This vertical path enables extremely high breakdown voltages (1.2–10 kV), low RDS(on), and high efficiency for demanding power applications including EV traction inverters, grid converters, solar inverters, and industrial motor drives.

Why Vertical GaN Matters

- High voltage: 1.2–10 kV capability

- High current density: Scalable device geometry

- Reduced conduction loss: Thick GaN drift layers

- Superior switching: Faster than SiC in many designs

- High reliability: Minimizes surface trapping & leakage

Vertical GaN Substrates We Provide

- 2", 4", and 6" bulk GaN wafers

- Low-defect GaN substrates for vertical devices

- Custom n-type drift layers

- Vertical MOSFET, diode, and SBD epitaxial stacks

- R&D and production-grade material

Quick Specification Table

| Parameter | Typical Value |

|---|---|

| Wafer Sizes | 2”, 4”, 6” bulk GaN |

| Defect Density | < 1×106 cm-2 |

| Drift Layer Thickness | 5–20 µm (custom) |

| Doping Type | n-type (Si-doped) |

| Voltage Capability | 1.2–10 kV |

| Surface Finish | Double-side polished |

| Custom Epitaxy | MOSFET, SBD, diode stacks |

Why Choose UniversityWafer, Inc.?

- Fast delivery on bulk GaN wafers

- Custom drift-layer epitaxy

- Vertical MOSFET, diode, and SBD structures

- Global support for universities and industry