Micropipes in Silicon Carbide Wafers

In silicon carbide (SiC), a micropipe is not a device feature that is “created” when the wafer

is cut. It is a crystallographic defect – a hollow‑core screw dislocation that forms during bulk crystal growth

and runs roughly along the growth direction (c‑axis) through the SiC boule. When the boule is sliced into wafers,

the micropipe intersects the surface as a small, usually circular or hexagonal pit with a hollow tube extending

deep into the substrate.

In silicon carbide (SiC), a micropipe is not a device feature that is “created” when the wafer

is cut. It is a crystallographic defect – a hollow‑core screw dislocation that forms during bulk crystal growth

and runs roughly along the growth direction (c‑axis) through the SiC boule. When the boule is sliced into wafers,

the micropipe intersects the surface as a small, usually circular or hexagonal pit with a hollow tube extending

deep into the substrate.

How Micropipes Form

Commercial SiC boules are typically grown by seeded sublimation, also known as physical vapour transport (PVT). During this process:

- A high‑quality SiC seed crystal is mounted in a graphite crucible (susceptor).

- SiC source powder sublimates at high temperature and re‑condenses on the cooler seed, thickening the crystal.

-

Under certain growth conditions – for example, unfavorable temperature gradients, high supersaturation,

impurities, or seed defects – large screw dislocations can develop hollow cores. These hollow‑core dislocations

propagate along the growth direction and become micropipes.

As the boule grows, a single micropipe can extend through many millimetres of crystal and therefore intersect a

large number of wafers cut from that boule.

Size and Electrical Impact

Typical micropipes in SiC have diameters on the order of 1–10 µm at the wafer surface – large enough that

even a single defect in a critical region can be a “killer” for high‑voltage or high‑power devices. A micropipe:

- Acts as a leakage path through the device structure.

- Distorts the local electric field and lowers breakdown voltage.

- Can be a preferred site for premature failure under high stress.

Because epitaxial layers grown on SiC typically inherit many defects from the underlying substrate, micropipes

originating in the bulk crystal can propagate into the epi and directly limit device performance.

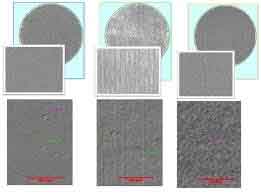

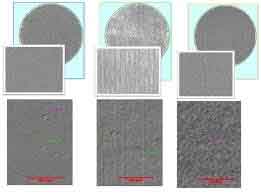

Micropipe Density (MPD)

To quantify substrate quality, manufacturers specify micropipe density (MPD) in units of

defects per square centimetre (cm−2). MPD is usually measured on the wafer surface by optical

inspection or X‑ray / synchrotron topography, and can be defined across the whole wafer or in specified

active areas.

Lower MPD directly translates into:

- Higher device yield on each wafer.

- Higher achievable breakdown voltage per unit chip area.

- Improved consistency and long‑term reliability in power and RF devices.

From Early SiC to “Micropipe‑Free” Wafers

Early generations of 4H‑ and 6H‑SiC substrates often exhibited micropipe densities of hundreds of defects per

cm2. Over the last two decades, improvements in seed quality, crucible design and growth process

control have reduced MPD by several orders of magnitude, to the point where state‑of‑the‑art power‑device

substrates are effectively micropipe‑free (MPD ≈ 0–1 cm−2).

For research and prototyping, however, material with a specified limit such as

MPD < 15 cm−2 can still be very useful, especially when device layouts are

designed to keep any remaining micropipes outside the active area. When you request SiC wafers or diced pieces,

including an explicit MPD requirement helps match the substrate quality to your application.

In silicon carbide (SiC), a micropipe is not a device feature that is “created” when the wafer

is cut. It is a crystallographic defect – a hollow‑core screw dislocation that forms during bulk crystal growth

and runs roughly along the growth direction (c‑axis) through the SiC boule. When the boule is sliced into wafers,

the micropipe intersects the surface as a small, usually circular or hexagonal pit with a hollow tube extending

deep into the substrate.

In silicon carbide (SiC), a micropipe is not a device feature that is “created” when the wafer

is cut. It is a crystallographic defect – a hollow‑core screw dislocation that forms during bulk crystal growth

and runs roughly along the growth direction (c‑axis) through the SiC boule. When the boule is sliced into wafers,

the micropipe intersects the surface as a small, usually circular or hexagonal pit with a hollow tube extending

deep into the substrate.