Order SAW Substrates for Sensor Development

UniversityWafer, Inc. supplies high-quality piezoelectric substrates for Surface Acoustic Wave (SAW) devices used in gas, chemical, biosensing, temperature, and pressure sensors. Our wafers support strong electromechanical coupling, excellent surface polish, and reliable acoustic performance ideal for both research and production environments.

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

Available SAW Substrate Materials

- Lithium Niobate (LiNbO3) – High coupling coefficient and sensitivity

- Lithium Tantalate (LiTaO3) – Superior thermal stability for harsh conditions

- Quartz (SiO2) – Low acoustic loss for precision sensing

- Langasite (LGS) – Exceptional stability at elevated temperatures

Common Orientations

- 128° Y-cut LiNbO3 – Industry standard for SAW sensors

- 36° Y-cut LiTaO3 – Stable temperature response

- Z-cut Quartz – Very low propagation loss

- Custom orientations upon request

Typical Specifications

- Diameters: 2", 3", 4", and custom

- Thickness: multiple options with tight tolerances

- Surface: DSP or SSP, epi-ready finishes

- Doping and custom cuts available

We work closely with researchers developing SAW sensors for environmental monitoring, medical diagnostics, industrial process control, wireless temperature sensing, and more. Our substrates are selected for stability, repeatability, and acoustic performance.

Related SAW Materials, Substrates, and Fabrication Resources

Lithium Tantalate (LiTaO₃) RF Properties for SAW DevicesLithium Niobate Substrates for SAW Sensors

Overview of SAW Device Applications in Sensor Technology

RF Filters Based on Lithium Tantalate SAW Technology

Thin-Film Lithium Niobate Applications in SAW and RF Devices

Polishing and Lapping Processes for SAW Sensor Wafers

Semiconductor Metrology for SAW Device Fabrication

Silicon Photonics Substrates and Photonic Crystal Fabrication

How SAW Technology Enables High-Sensitivity and Wireless Sensor Performance

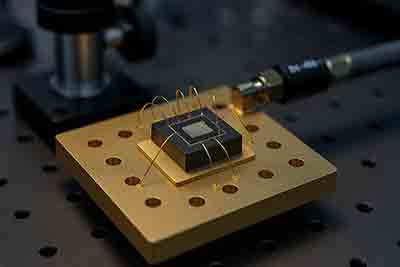

Surface Acoustic Wave (SAW) devices play a crucial role in modern sensing technologies due to their sensitivity to mass loading, temperature, pressure, chemical interactions, and surface perturbations. Built on piezoelectric substrates, SAW sensors convert electrical signals into mechanical waves that travel across the surface of the material. Any change on the surface alters wave velocity or amplitude, enabling precise detection.

How SAW Sensors Work

A typical SAW device consists of interdigitated transducers (IDTs) patterned onto a piezoelectric substrate. When an electrical signal excites the IDTs, mechanical waves propagate along the surface. If the surface interacts with gas molecules, chemicals, biological agents, or mechanical forces, the wave characteristics change, allowing the device to function as a high-sensitivity sensor.

Gas and Chemical Sensing

SAW sensors are widely used for gas and chemical detection because their surface wave propagation is strongly influenced by mass loading and surface interactions. By applying a selective coating—such as polymers, metal oxides, or functionalized films—SAW devices can selectively detect volatile organic compounds, industrial gases, and environmental pollutants with high specificity.

Biosensing and Medical Diagnostics

In biosensing applications, SAW devices detect biomolecules through surface binding events. When biological agents such as proteins, antibodies, or pathogens adhere to the coated surface, the added mass shifts the acoustic wave frequency. This enables label-free, real-time detection for medical diagnostics, point-of-care testing, and biochemical research.

Pressure and Strain Measurements

Mechanical forces such as pressure or strain modify the surface properties of the piezoelectric substrate, altering SAW propagation velocity. This makes SAW devices ideal for high-precision pressure sensors in automotive, aerospace, and industrial equipment. Their small size and robustness allow integration into compact or harsh-environment systems.

Temperature Sensing and Thermal Stability

Because SAW frequency is temperature-dependent, these devices serve as accurate temperature sensors. Specific cuts of lithium tantalate, lithium niobate, or quartz offer predictable thermal coefficients, enabling highly stable temperature measurement over wide ranges. Wireless, passive SAW temperature sensors are especially valuable in environments where electronics cannot operate.

Wireless and Passive SAW Sensors

One of the most powerful advantages of SAW devices is their ability to function wirelessly without a local power source. By using RF interrogation, SAW sensors can operate as fully passive tags, making them ideal for rotating machinery, sealed systems, high-temperature environments, and remote sensing applications.

Why Substrate Choice Matters

The performance of a SAW sensor depends heavily on its substrate material. Electromechanical coupling, acoustic velocity, temperature stability, and sensitivity are all functions of the crystal structure and orientation. Common materials include:

- Lithium Niobate (LiNbO3) – High sensitivity due to strong coupling.

- Lithium Tantalate (LiTaO3) – Excellent thermal stability.

- Quartz (SiO2) – Low acoustic loss for precision sensing.

- Langasite (LGS) – Robust for extreme temperature environments.

SAW Sensors in Real-World Industries

SAW technology enables reliable, high-performance sensors across a wide range of industries:

- Environmental monitoring (gas leaks, VOCs, pollutants)

- Healthcare and medical diagnostics

- Food safety and contamination detection

- Aerospace and automotive pressure sensing

- Industrial and manufacturing process control

- Wireless temperature and strain measurement

As demand grows for compact, low-power, and highly sensitive sensors, SAW devices remain one of the most versatile platforms for next-generation sensing solutions.