Why Use Neutron Transmutation Doped (NTD) Silicon

Neutron Transmutation Doped (NTD) Float Zone Silicon is used in semiconductor devices that have to work in extreme environments including space. NTD silicon has the lowest resistivity range of any crystalline silicon wafer.

NTD SIlicon Benefits

• Tightest resistivity tolerances of any silicon wafer

• Lowest impurity levels

• Highest minority carrier lifetime

We have very few requests for NTD Silicon, fewer than in the past.

Currently FZ Silicon can be chemically doped with greater resistivity uniformity (both radially and much better radially) than in the past, so now NTD Silicon has fewer advantages.

But if you need NTD-Silicon, let us know and we'll quote!

Get Your NTD Silicon Quote FAST! Or, Buy Online and Start Researching Today!

Silicon Neutrons Applications

The use of silicon neutrons in various applications is growing, from medical imaging to forensic science. These powerful particles can be used for a variety of scientific research. Scientists are also investigating new ways to detect radioactive materials, including uranium. One of the most promising uses of silicon neutrons is in nuclear physics. While these particles are very rare, their high-energy content and short decay time make them an ideal target for neutron studies.

Because silicon neutron detectors are inexpensive, easy to fabricate, and integrate with readout electronics, they are a good choice for many applications. One such application is in thermal neutron capture. Researchers have also used silicon neutron detectors coated with natural or enriched boron carbide to study the reactions that occur during thermal neutron capture. The neutrons deposited onto the surfaces of these devices are highly transparent to neutrons.

Silicon neutron detectors are ideal candidates for many applications. Since they operate at low voltage, they are easy to fabricate and integrate with readout electronics. Because silicon is transparent to neutrons, it is attractive for use in a wide range of medical and science applications. For example, it has been used in thermal neutron capture experiments with boron carbide, which is a good material for thermal neutron detection.

Another application for silicon neutrons involves the study of silicate rocks, which consist of silicon surrounded by four oxygen atoms. They are called silicate rocks, as the silicate rock's structure is shaped like a mad tangle of chains. In some instances, phosphorus atoms act as donors in the silicon crystal lattice. This makes them ideal for a number of scientific experiments.

The cross section of silicon is relatively small, which makes the use of silicon neutrons advantageous. Because of the small cross section, neutrons are readily captured in the material. The average path for the captured neutrons is a few meters. As a result, the use of silicon in large-volume nuclear radiation detectors is a natural candidate for industrial uses. If the technology can be scaled up to the industrial scale, the results will be highly beneficial for the semiconductor industry.

The technology for silicon neutrons is still in its early stages. Despite the fact that it is more expensive than a conventional magnet, the technology is available at a low cost and is becoming more common. It is possible to build a device using two or more NSL in series, thus achieving full 3-dimensional focusing. The application of silicon neutrons in semiconductor manufacturing is huge, and the advantages of these detectors far outweigh the drawbacks of traditional methods.

The light wavelength of silicon neutrons is very short and the energy density of the beams is low. It is also very hard. A high-frequency electron beam will cause a semiconductor to melt. In addition, a silicon laser is not a perfect mirror, but it will not create the most luminous object possible. However, a high-power neutron beam will be very intense, making it an ideal candidate for high-frequency radiation sources.

A silicon neutrons device is not only a good semiconductor detector, but it also allows for the creation of electrically active impurities. Its high energy means that silicon neutrons are ideal for various applications, including nuclear physics. These radiation detectors can be used for a variety of purposes, including medical imaging. A neutrons beam can be used for a number of different purposes, including in diagnostics, research, and even defense.

A silicon neutrons device is a silicon laser that consists of multiple mirrors separated by silicon wafers. This type of device can focus primary and scattered beams in three dimensions. Moreover, it is also extremely compact, requiring only small sample sizes. Its design can be made from single crystal silicon and is also based on ellipsoidal surfaces. This optical design is similar to that of a laser.

The silicon program uses a special ion beam to irradiate silicon materials for semiconductors and microcircuits. Its irradiation system utilizes four-inch and six-inch crystals. The MIT-NRL silicon lab can provide this service to customers as well. It is also the only facility in the United States that offers this specific type of treatment. The MIT-NRL Silicon program irradiates semiconductor materials for different applications. This unique radiation process enables the creation of ultra-high-quality products.

How Many Neutrons Are in Silicon?

In order to find out how many neutrons are in silicon, we need to know its atomic mass. The atomic mass of silicon is 14 protons and 14 electrons. The number of protons in an atom is equal to the number of neutrons. In a neutral atom, there are four electrons in the outer ring. The atomic mass of silicon is the same as the mass of carbon, and the atomic mass of nitrogen is the same as the mass of oxygen.

The atomic number of silicon is 14. Its atomic number is represented by the symbol Z. The total electrical charge of the silicon nucleus is equal to +Ze. This total e is equivalent to 1,602 x 10-19 coulombs. The atomic mass of a solid is equal to the sum of the atomic mass and the number of neutrons. The atomic mass is also called the atomic number.

The atomic mass of silicon is equal to 14 x 10-18 coulombs. The atomic number of silicon is determined by the atom's ionization energy. Its ionization energy is equal to 1.53 x 10-20 coulombs. The atom's total number of neutrons is equal to its atomic mass. The difference is known as its neutron excess.

What is Silicon Neutrons?

The high energy of the silicon neutron device means silicon neutrons are perfect for a variety of applications, including nuclear physics. If silicon neutron technology is scaled up to industrial size, then the results would greatly benefit the semiconductor industry. Bulk doping can be achieved through nuclear transmutation, irradiating pure silicon with neutrons in a nuclear reactor.

By doping pure silicon with V-group elements, such as phosphorus, additional valence electrons are added, which are decoupled from individual atoms and enable the compound to become an electrically conductory N-type semiconductor. As neutrons continue to pass through silicon, more phosphorus atoms are produced through transmutation, and so the doping becomes increasingly strongly n-type. As neutrons continue to pass through the silicon, more and more phosphorus atoms are produced by transmutation, and thus the doping becomes more and more strongly n-type. This bond forms a single crystal with the oxygen content, which brings scattered intermediates and the core silicon much closer together, potentially creating a new kind of NTD high-oxygen silicon.

| Isotope Symbol | Protons | Electrons | Atomic Number | Mass Number | |

| With 14 Neutrons: | |||||

| With 15 Neutrons: | |||||

| With 16 Nuetrons: |

The silicon atom contains fourteen protons and 14 electrons. In a drawing of an atom, we can see that it has a nucleus with fourteen protons. The outer ring, or valence electrons, contains four neutrons. Each of these atoms has four valence electrons, which are essentially charged with antimatter. They make the atom strong and durable, but they are also light.

The number of protons and electrons in a given atom determines its chemical behavior. In a periodic table, elements are listed in increasing order of their atomic number. For example, the atomic number (Z) of silicon is 14, which indicates that there are fourteen protons in the nucleus and fourteen electrons. The atomic mass number (M) is the total number of neutrons in the atom, while the atomic number is equal to the number of protons in the c-ray.

The number of electrons in a silicon atom is the same as the number of protons in the atom. An atomic nucleus has 14 protons and a total of 14 electrons, called its atomic mass. A neutral atom has a valence electron. Its valence electrons are responsible for the silicon atom's yellowish colour, while its valence a negative one.

When an atom is electrically neutral, it has the same number of protons as it does electrons. A silicon atom has 14 protons. If it has fifteen, it is no longer a silicon atom. If it has four or more, it is phosphorus. It has an equal number of electrons and protons. Therefore, the atomic mass of silicon is 14. The atomic mass of silicon is 14, which is its atomic number.

During a reaction, silicon has a positive charge that is neutral. The positive charge is positive, so it is negative. A neutral atom has 14 protons and a negative charge, which makes it neutral. A neutral atom has one atomic mass. In comparison, a hydrogen atom has two protons and nine electrons. Its atomic mass is one hundred and fourteen protons and four electrons.

While hydrogen and oxygen have similar charges, hydrogen and silicon are heavier than oxygen. This is because the hydrogen atoms in hydrogen and oxygen are more dense than hydrogen, so the positive charge of oxygen is higher than that of the sulfur atom. But this does not mean that it is heavier than silicon. Its atomic mass is seven times lighter than that of iron, which means that it is heavier than sulfur. And the atomic mass of aluminum is eight times smaller than that of silicon.

Silicon is an abundant element, with fourteen protons and 14 electrons. In its atomic nucleus, the element has a total of 14 protons, which is the atomic number. The atomic mass of an atom is its atomic number, or "atomic number". In the same way, the corresponding atomic mass is its atomic number. When the elements in nature are bonded together, they create the atoms, which contain the corresponding atoms.

The number of silicon neutrons in a silicon atom is referred to as its atomic mass. The number of protons and electrons in a silicon atom are equivalent in the atomic number of the silicon atom. Hence, a silicone molecule contains 14 neutrons and one proton. The two are opposites of each other. As such, they are opposites of each other.

How Many Protons Neutrons and Electrons Does Silicon Have?

A neutron has only slightly more mass than a proton, but even its mass is generally assumed to be a single atomic unit. Selenium has 34 protons and 45 neutrons in its nucleus, giving it an atomic number of 34 and atomic mass of 79. Silicon is a chemical element with atomic number 14, meaning that its nucleus has 14 protons.

What Is the Number of Neutrons in Silicon?

Silicon is a chemical element with an atomic number of 14, meaning it has 14 protons in its nucleus. All the other elements have neutrons and protons in their nuclei, like Helium, shown in figure 2.2. For most of the remaining elements, neutrons outnumber protons, as additional neutrons are needed to hold the nucleus together by outweighing the mutual repulsion from an increasing concentration of protons concentrated in a minimal area.

What are NTD Silicon Wafers?

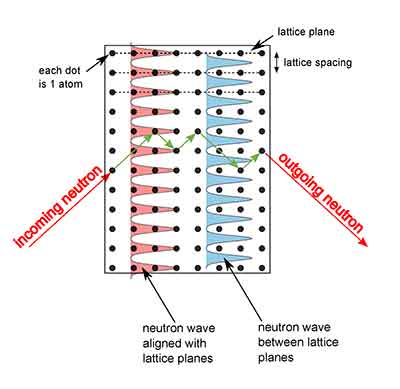

Float Zone (FZ) NTD Silicon Wafer breaks through traditional methods for the preparation of single-crystal silicon, bringing a new energy into the silicon materials process. UniversityWafer, Inc. offers FZ Neutron Transmutation Doping (NTD) Silicon Wafers, which have a uniform doping concentration and uniform radial resistivity distribution. Neutron transmutation doping (NTD) is a novel process using neutrons to convert low-purity silica sand to high-purity silicon.

300mm silicon wafer diameter can be irradiated with neutrons to obtain a high-energy neutron beam (e.g. a laser or electron beam). A wide range of silicon wafers irradiate a neutron and a range of different semiconductor types, such as silicon nanotubes, silicon oxide or silicon nitride.

As neutrons continue to travel through silicon, transmutation produces more and more phosphorus atoms, and therefore doping becomes more and more of type N. This bond forms a single oxygen-containing silicon crystal, bringing the scattered intermediates and the intermediate silicon closer together, possibly creating a new type of high-oxygen NTD silicon. Carbon and oxygen are retained as oxygen and carbon silicon and are not affected by the NTD process. A new acceptor and donor are discovered and an electrically active role for hydrogen is established. [Sources: 1, 2, 3, 4]

When NTD is applied to a single silicon crystal, the heat treatment can recover the electrical resistance and life of the carrier. If it suffers from a defect in the centre of the crystal (e.g. a centre of mass defect), it can settle at 800 degrees. However, if it is obtained using the FZ-N-TD method, it cannot recover this medium defect and can only restore electrical resistance, carrier and service life. [Sources: 1] -N-TD method on a single silicon crystal (e.g. in a silicon chip).

NTD works best with silicon ingots of less than 1 mm diameter and 0.5 mm thick. To minimize the effects of inhomogeneity, the silicon ingots and bars are rotated so that neutron irradiation is carried out on both sides. The semiconductor wafers are then measured to determine whether residual radiation is present. A silicon ingot with a diameter of 200 mm is irradiated on a wafer that is rotated during irradiation. ources:

[0]: https://nrl.mit.edu/facilities/ntds

[1]: https://patents.justia.com/patent/4910156

[2]: https://en.wikipedia.org/wiki/Doping_(semiconductor)

[3]: https://www.science.gov/topicpages/t/transmutation+doped+ntd

[4]: https://www.freepatentsonline.com/y2020/0005957.html

Number of Protons Neutrons and Electrons in Silicon

The atomic number of silicon is 14, and so the number of protons and electrons in a ![]() chargeless silicon atom is also 14. This means if we have 14 positive charges, then we have to define the number of electrons because electrons are negatively charged. For most of the remaining elements, neutrons outnumber protons, since the additional neutrons are needed to hold the nucleus together, by outcompeting the mutual repulsion from an increasing number of protons concentrated in a very small area.

chargeless silicon atom is also 14. This means if we have 14 positive charges, then we have to define the number of electrons because electrons are negatively charged. For most of the remaining elements, neutrons outnumber protons, since the additional neutrons are needed to hold the nucleus together, by outcompeting the mutual repulsion from an increasing number of protons concentrated in a very small area.