Need High-Quality Substrates for Nanofluidics?

We supply cleanroom-ready wafers for single-molecule sensing, nanochannel fabrication, and ion-transport studies.

Choose the following substrate:

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

What to Include in Your Nanofluidics Request

- Material: Si, fused silica, borosilicate glass, SOI, quartz, sapphire, etc.

- Wafer size: 100 mm, 150 mm, other diameters or chips.

- Thickness range and tolerance.

- Surface finish: SSP/DSP, roughness, low particle level requirements.

- Channel or pore depth and width targets (e.g., 20–100 nm channels).

- Bonding method: anodic, thermal, adhesive, plasma-assisted, etc.

- Special needs: alignment marks, through-holes, membranes, coatings.

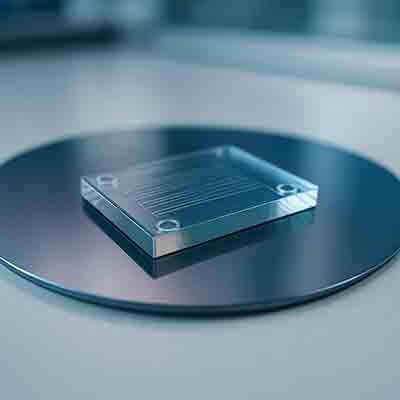

Nanofluidics Substrates & Devices

At UniversityWafer, Inc., we provide high-quality substrates and fabrication-ready wafers designed specifically for nanofluidic applications. Researchers developing nanochannels, nanopores, and lab-on-a-chip devices rely on precise materials to ensure smooth surfaces, accurate feature definition, and compatibility with cleanroom processing. Our silicon, glass, and custom substrates support advanced nanofluidic research in biosensing, DNA analysis, ion transport, and other nanoscale fluid studies.

What is Nanofluidics?

Nanofluidics refers to the study and control of fluid flow through structures with at least one dimension in the nanometer scale (typically 1–100 nm). In such confined geometries, fluids and ions behave very differently compared to macro- or micro-scale flows. Surface effects, electrostatic interactions, molecular confinement, and ionic transport dominate, enabling unique phenomena such as single-molecule sensing, size-based separation, ionic selectivity, and ultra-small volume manipulation.

Why Substrate Quality Matters

Because nanofluidic devices rely on nanoscale features, the underlying substrate’s quality becomes critically important. Surface roughness, defects, thickness uniformity, and flatness all influence how precisely channels or pores can be fabricated and how reliably fluid flows. Using polished, defect-free wafers ensures reproducible channel geometry, stable bonding (for stacked devices), and compatibility with lithography and etching processes.

What We Offer

We offer a wide selection of substrates suitable for nanofluidic device fabrication:

- Silicon wafers — polished Si for top-down nanopatterning and etching.

- Glass & fused silica wafers — for optical transparency and bio-compatibility.

- SOI wafers — precise control of channel depth via device layer thickness.

- Quartz and sapphire — for optical, thermal, and chemical robustness.

- Custom materials and coatings — membranes, nitride, oxide, and 2D materials.

Typical Nanofluidic Applications

Common uses of nanofluidic substrates include:

- Single-molecule analysis & DNA sequencing using nanochannels and nanopores.

- Biosensing & diagnostics in lab-on-chip platforms.

- Ion transport & filtration for separation, desalination, and blue-energy devices.

- Nanoscale fluid dynamics research exploring electrokinetics and confinement effects.

Nanofluidic Device Examples and Research Use-Cases

Below are real-world examples of how researchers use our silicon, glass, and specialty substrates to fabricate nanofluidic devices. These applications highlight common requirements for nanochannels, nanopores, and hybrid micro-/nanofluidic systems.

Example 1 — Nanochannels for DNA Stretching

A biotechnology research group contacted us requesting 100 mm double-side polished silicon wafers for top-down fabrication of nanochannels used in DNA stretching experiments. Their process required extremely smooth surfaces and low-defect wafers to pattern channels between 50–150 nm wide, with tight thickness control for uniform etch depth.

“We are fabricating nanochannels for DNA folding and stretching studies and need high-flatness wafers for uniform etching. Can you recommend appropriate Si wafers for this?”

We supplied DSP wafers compatible with their e-beam lithography and DRIE workflow. The customer reported excellent uniformity across the device arrays.

Example 2 — Nanopores for Single-Molecule Sensing

A physics department building solid-state nanopores reached out for borosilicate glass wafers to integrate with a silicon nitride membrane. Their project aimed to detect individual biomolecules through ionic current measurements, requiring low-stress substrates that withstand thermal and chemical processing.

“We’re drilling nanopores in SiN membranes and need glass wafers for bonding and optical alignment. Do you offer high-purity glass wafers in custom thicknesses?”

We provided custom glass substrates that met their bonding and transparency requirements, enabling clear optical access to the nanopore region.

Example 3 — Hybrid Micro/Nanofluidic Devices

Another customer developing a portable diagnostic device needed silicon wafers for the nanofluidic region and glass covers for optical detection. The device integrated micron-scale reservoirs with 20–80 nm channels, so both mechanical stability and optical clarity were essential.

“Our prototype combines microfluidic reservoirs with nanochannels etched into silicon. We need a wafer stack that bonds reliably without trapping particles.”

We supplied silicon substrates with controlled surface roughness and glass pieces polished to tight tolerances, allowing the team to assemble leak-free stacked structures.

Example 4 — Ion Transport & Energy Harvesting Devices

A materials science team studying ion-selective transport through nanochannels requested wafers with exceptional surface smoothness to minimize scattering effects. Their research focused on ion mobility, electrokinetic flow, and osmotic energy conversion across nanostructured membranes.

“We are investigating blue energy generation using nanochannels and need wafers that ensure uniform channel performance across the device.”

We provided DSP silicon wafers optimized for uniformity and surface chemistry treatments compatible with their experimental needs.

Materials for Nanofluidic Devices

Many nanofluidic chips combine multiple materials to balance optical, electrical, and mechanical requirements. Popular choices include:

- Silicon wafers for nanochannel etching and integration with CMOS processes.

- Fused silica wafers for deep-UV transparency and chemical resistance.

- Borofloat 33 and other borosilicate glasses for bonding and optical access.

- Silicon nitride on silicon for nanopore membranes and dielectric layers.

- Graphene and 2D materials for advanced sensing interfaces.

- Sapphire wafers for high-temperature and high-strength environments.

Key Design & Fabrication Considerations

- Channel dimensions: height/width in the 10–100 nm range require ultra-smooth and flat substrates.

- Surface roughness: low roughness minimizes scattering and adsorption, critical for single-molecule work.

- Surface charge & chemistry: controls electroosmotic flow, ionic selectivity, and biomolecule interactions.

- Bonding method: anodic, thermal, adhesive, or plasma bonding must be compatible with the substrate materials.

- Alignment: accurate front/back alignment is needed for overlay of micro- and nanoscale structures.

Typical Nanofluidic Process Flow

- Start with polished silicon, glass, or fused silica wafers.

- Clean and prepare surfaces (RCA, piranha, or solvent cleaning as appropriate).

- Deposit or grow functional layers (e.g., SiN, SiO₂) if needed.

- Pattern nanochannels or nanopores via e-beam, DUV lithography, or focused-ion-beam.

- Etch structures using RIE/DRIE or wet etching, depending on the material.

- Bond a second wafer or cover plate to enclose channels.

- Dice, package, and connect to microfluidic interfaces and electronics.

Related UniversityWafer Resources

- Nanofabrication wafers and services

- Microfluidics substrates

- SOI wafers for channel depth control

- Complete wafer products overview

- Contact us to discuss your nanofluidic device requirements.