Essential Factors When Selecting Custom Wafer Sizes

- Consider application requirements (MEMS, photonics, power devices)

- Standard sizes include 3-inch, 8-inch (200mm), and 12-inch (300mm)

- Material selection impacts available sizes and specifications

- Cost efficiency improves with larger wafers for high-volume production

- Equipment compatibility should be verified before ordering

Get Your Quote FAST! Buy Online and Start Researching Today!

Selecting the right wafer size for your semiconductor project is a critical decision that impacts manufacturing costs, yield, and performance. Whether you're developing prototypes for research or planning mass production, understanding the factors that influence wafer size selection can save time and resources. This guide will help you understand the important considerations involved in choosing custom wafer sizes for your specific application needs.

At UniversityWafer, we provide a wide range of wafer sizes and materials to meet diverse requirements across industries. From standard silicon wafers to specialized materials like sapphire and silicon carbide, our inventory supports applications from basic research to advanced device fabrication. Our technical experts can guide customers through the selection process, ensuring optimal specifications for each unique project requirement.

Standard Wafer Sizes and Industry Trends

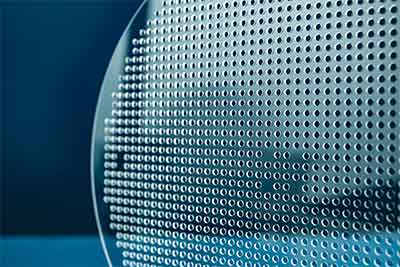

The semiconductor industry has moved toward larger wafer diameters to improve manufacturing efficiency and reduce costs per device. While 300mm (12-inch) wafers are now mainstream in high-volume manufacturing, many applications still use smaller wafers for specialized needs or cost reasons. This shift to larger diameters has been driven by economics, as larger wafers can produce more chips per manufacturing cycle, reducing the overall production cost per chip.

Understanding the standard sizes available in the market is the first step in determining the most appropriate wafer size for your application. Each size offers different advantages in terms of cost, compatibility with equipment, and production volume capabilities. The selection of the right substrate is crucial for ensuring optimal performance of your semiconductor devices. Different substrate materials and specifications can significantly impact device characteristics such as speed, power consumption, and reliability.

Common Wafer Sizes in Today's Market

Today's semiconductor industry uses a range of wafer sizes, each serving different applications and production volumes:

- 3-inch (76.2mm) - Still widely used for research, specialized applications, and legacy production lines. These smaller wafers remain popular in academic settings and for niche technologies where the economics of larger wafers don't apply.

- 4-inch (100mm) - Popular for MEMS, sensors, and specialized devices. This size offers a good balance between cost and usability for many specialized applications and smaller production runs.

- 6-inch (150mm) - Common for power electronics and discrete components. The 6-inch platform provides sufficient area for these typically larger devices while maintaining reasonable processing costs.

- 8-inch (200mm) - Widely used for analog chips, MEMS, RF devices, and many mature technology nodes. This size represents an excellent compromise between manufacturing efficiency and capital equipment costs.

- 12-inch (300mm) - Standard for high-volume advanced logic and memory production. These wafers maximize production efficiency for leading-edge technologies and high-volume manufacturing operations.

Our 3-inch silicon wafers remain popular for research applications and specialized production needs. These smaller wafers offer cost-effective solutions for projects that don't require the higher die counts of larger wafers. They're particularly valuable for university research labs and small-scale prototyping, where budget constraints often limit material expenditures. The lower cost per wafer allows researchers to conduct more experimental iterations while minimizing financial risk during process development stages.

For high-volume production of advanced devices, our 12-inch sapphire wafers provide excellent optical quality and durability. These larger wafers maximize production efficiency for applications requiring sapphire's unique properties, such as LED manufacturing, RF devices, and optical components. The larger diameter allows manufacturers to produce more devices per processing cycle, significantly reducing the cost per device while maintaining the exceptional material properties that make sapphire valuable for these specialized applications.

Material Considerations in Wafer Size Selection

Different semiconductor materials have varying availability in specific wafer sizes. This is due to technical challenges in crystal growth, processing capabilities, and market demand. When selecting a custom wafer size, the material properties and availability must be carefully considered to ensure compatibility with your application requirements. The crystalline structure, thermal properties, and mechanical characteristics of different materials present unique challenges in wafer manufacturing that directly impact available size options.

The choice of material affects not only the available sizes but also the electrical, thermal, and mechanical properties of the final device. Each material has unique characteristics that make it suitable for specific applications, from high-power electronics to optical devices. Understanding these material-specific limitations is essential for making informed decisions about wafer specifications that will ultimately determine device performance, reliability, and manufacturing feasibility.

Silicon Wafers

Silicon remains the most versatile and widely available wafer material across all standard sizes. From 3-inch to 12-inch, silicon wafers can be manufactured with precise specifications for dopant type, resistivity, and surface finish. Silicon's abundance, well-established processing techniques, and excellent semiconductor properties make it the material of choice for most electronic applications. The mature silicon crystal growth technologies, particularly the Czochralski process, enable the production of large-diameter single-crystal ingots with exceptional quality and consistency.

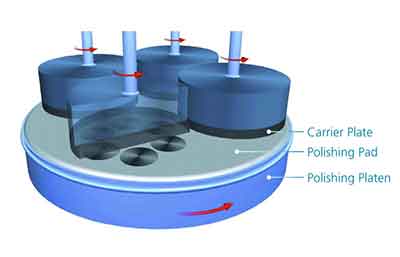

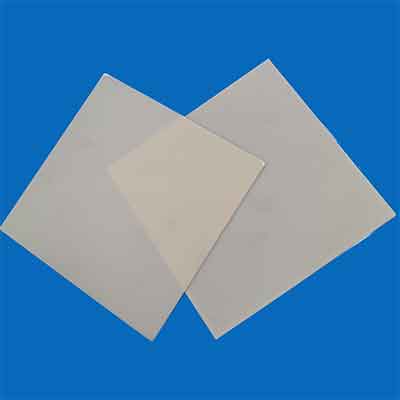

Our polished silicon wafers are available in various specifications, including single-side polished (SSP) and double-side polished (DSP) options. The polishing process is critical for ensuring surface quality needed for successful device fabrication. The choice between SSP and DSP depends on your specific application requirements and processing methods. SSP wafers are typically used when only one side requires a mirror-like finish for device fabrication, while DSP wafers are essential for applications requiring processing on both sides or for optical applications where light transmission through the wafer is necessary.

Compound Semiconductors

Materials like silicon carbide (SiC) and gallium arsenide (GaAs) have different size availability compared to silicon due to the challenges in growing large, defect-free crystals of these materials:

- Silicon Carbide (SiC): Commonly available in 2-inch, 3-inch, 4-inch, and 6-inch diameters, with 8-inch becoming more accessible. The extreme hardness and high melting point of SiC present significant challenges in crystal growth and wafer processing, limiting the maximum practical diameter compared to silicon.

- Gallium Arsenide (GaAs): Typically available in 2-inch, 3-inch, 4-inch, and 6-inch diameters. GaAs crystal growth faces challenges related to maintaining stoichiometry and preventing arsenic loss during the high-temperature growth process, which complicates the production of larger diameter wafers.

- Gallium Nitride (GaN): Often grown on sapphire or silicon substrates in sizes up to 6-inch. The heteroepitaxial growth of GaN introduces additional complexities related to lattice matching and thermal expansion coefficient differences, further constraining available size options.

Our silicon carbide wafers are available in both 4H and 6H polytypes with various specifications. These wafers are ideal for power electronics, high-frequency devices, and applications requiring operation in extreme conditions. The wide bandgap properties of SiC make it superior to silicon for high-temperature and high-voltage applications. The 4H polytype offers higher electron mobility and is preferred for power devices, while the 6H polytype has unique properties that make it suitable for specific optoelectronic applications and some sensing technologies.

Specialized Materials

For specialized applications, materials like sapphire and glass offer unique properties but may have more limited size options:

- Sapphire: Available in sizes from 2-inch to 8-inch, with limited 12-inch availability. Sapphire's extreme hardness (9 on the Mohs scale) and high melting point (2030°C) make large-diameter crystal growth and wafer processing particularly challenging and costly.

- Glass: Available in various sizes and thicknesses, often customizable. Unlike crystalline semiconductors, glass substrates can be manufactured in larger sizes using different production methods, offering greater flexibility in dimensions but different electrical and thermal properties.

- Quartz: Typically available in sizes up to 6-inch. High-purity quartz wafers are essential for specialized applications requiring excellent thermal stability and RF transparency, but the material properties limit cost-effective scaling to larger diameters.

Our gallium arsenide solar cells demonstrate the superior efficiency of compound semiconductor materials in photovoltaic applications. With efficiency ratings up to 24.3% for single-junction cells, these materials are ideal for high-performance solar applications, including space exploration where power-to-weight ratio is critical. The direct bandgap of GaAs allows for much thinner active layers compared to silicon, resulting in lightweight, flexible solar cells that maintain high efficiency even under concentrated sunlight or elevated temperatures, making them particularly valuable for specialized applications despite their higher production costs.

Application-Specific Size Selection

The intended application of your semiconductor devices plays a crucial role in determining the optimal wafer size. Different applications have varying requirements for feature size, yield, and cost considerations. Matching the wafer size to your specific application needs ensures the most efficient use of resources and optimal device performance. Factors such as device complexity, critical dimensions, and process technology node all influence the ideal wafer diameter for a particular application.

When selecting a wafer size for your application, consider factors such as the number of devices needed, the size of individual devices, and the complexity of the fabrication process. The right choice balances technical requirements with economic considerations. For instance, applications requiring advanced lithography with extremely small feature sizes often necessitate larger wafers to maintain process uniformity across the substrate, while simpler devices with larger features may be more cost-effectively produced on smaller wafers.

Research and Development

For research and prototype development, smaller wafers (2-inch to 4-inch) often provide the best balance of cost and usability:

- Lower cost per wafer allows for more experimental iterations, enabling researchers to test multiple process variations without excessive material expenses

- Easier handling in laboratory settings, particularly important in academic environments where specialized wafer handling equipment may be limited

- Compatible with more widely available research-grade equipment, which is typically designed to accommodate smaller wafer sizes

- Sufficient for producing test devices and proof-of-concept demonstrations without the need for large device quantities

Our blog features articles on cutting-edge research applications using various wafer sizes and materials. These resources can help researchers select the most appropriate specifications for their projects, providing insights into the latest developments in semiconductor technology and applications. Many academic institutions leverage smaller wafer sizes to maximize research budgets while still achieving significant scientific breakthroughs, as demonstrated by numerous case studies featured in our educational resources.

Power Electronics

Power devices often use silicon carbide and gallium nitride wafers in 4-inch to 6-inch sizes. These sizes balance manufacturing costs with performance requirements, providing sufficient area for larger power device geometries without the higher expenses of larger wafers. They accommodate the larger device geometries common in power applications, where individual components may require more substrate area than typical integrated circuits. These wafer sizes also provide sufficient thermal management capabilities, critical for high-power devices that generate significant heat during operation. They're compatible with specialized equipment for wide-bandgap materials, which is often optimized for these intermediate wafer sizes.

Our aluminum nitride on silicon wafers provide excellent thermal conductivity for power electronics applications. This material combination is particularly valuable for RF filters, power amplifiers, and MEMS devices requiring superior thermal management. The thermal conductivity of AlN (170 W/(m·K)) makes it an excellent choice for high-power density applications. The aluminum nitride layer effectively dissipates heat generated during device operation, preventing thermal runaway and extending device lifetime under high-load conditions, while the silicon substrate provides mechanical stability and compatibility with standard processing equipment.

MEMS and Sensors

MEMS (Microelectromechanical Systems) and sensor applications often use 6-inch to 8-inch wafers. These sizes provide a good balance between manufacturing cost and yield, critical for the price-sensitive consumer electronics market where many MEMS devices are deployed. They accommodate the relatively large feature sizes of many MEMS devices, which typically don't require the most advanced lithography nodes but benefit from the increased area efficiency. These wafer sizes are compatible with specialized MEMS fabrication equipment, which is often designed specifically for these intermediate wafer sizes. They're suitable for volume production of consumer and industrial sensors, offering sufficient economies of scale without requiring the highest-cost 300mm fabrication facilities.

Our silicon-on-insulator (SOI) wafers are ideal for MEMS applications, providing excellent mechanical strength and electrical isolation. These wafers enable the development of highly efficient RF devices, microprocessors, and photonic integrated circuits. The buried oxide layer in SOI wafers provides unique advantages for device isolation and performance. The thin active silicon layer on top of the insulating oxide allows for complete dielectric isolation between adjacent devices, reducing parasitic capacitance and improving switching speed while simultaneously providing an ideal platform for creating suspended mechanical structures essential for many MEMS devices.

High-Volume Production

For high-volume commercial production of advanced logic and memory chips, 300mm (12-inch) wafers are the industry standard. These wafers maximize die count per wafer, reducing per-die manufacturing costs by as much as 30-40% compared to 200mm wafers for equivalent devices, dramatically improving production economics for high-volume products. They're optimized for leading-edge lithography equipment, which is designed to achieve maximum precision and throughput on 300mm platforms. These large wafers support the most advanced process nodes (5nm and below), where extremely tight process control and uniformity are essential across the entire substrate. They enable economies of scale for high-volume production, with fabrication facilities capable of processing thousands of wafers per week.

Economic Considerations in Wafer Size Selection

The economics of wafer size selection involve balancing initial costs against long-term production efficiency. Understanding these factors is crucial for making informed decisions that optimize your manufacturing budget while meeting technical requirements. The total cost of ownership includes not only the wafer cost itself but also processing expenses, equipment depreciation, yield factors, and throughput considerations, all of which vary significantly with wafer diameter.

While larger wafers generally offer better economics for high-volume production, they also require higher initial investment in materials and equipment. The right choice depends on your production volume, budget constraints, and time-to-market requirements. For startups and smaller companies, the capital expenditure required for larger wafer processing may be prohibitive, making intermediate sizes more economically viable despite slightly higher per-device costs in the long run.

Cost Per Die Analysis

Larger wafers generally result in lower cost per die for high-volume production, but this advantage must be weighed against higher initial costs:

- Wafer Cost: Larger wafers have higher unit costs but provide more usable area. For example, a 300mm wafer costs approximately 2.5 times more than a 200mm wafer but offers 2.25 times more surface area, potentially improving overall economics.

- Equipment Compatibility: Larger wafers require more expensive processing equipment, with 300mm fabrication facilities costing billions of dollars to establish compared to the more modest investment required for 200mm or smaller facilities.

- Yield Considerations: Defect density impacts the percentage of functional dies. As wafer size increases, maintaining consistent yield across the entire surface becomes more challenging, potentially offsetting some of the theoretical area advantages.

- Edge Effects: The proportion of partially usable dies at the wafer edge decreases with larger wafers. On a 300mm wafer, edge effects impact a smaller percentage of the total area compared to smaller wafers, improving overall material utilization.

Our silicon substrates are available in various grades to match your specific application requirements. Whether you need high-resistivity wafers for RF applications or standard silicon for general-purpose devices, we provide options to optimize your cost-performance balance. The selection of appropriate substrate specifications can significantly impact both device performance and manufacturing economics, making it essential to choose the right grade for your specific application rather than defaulting to the highest-specification material unnecessarily.

Volume Considerations

Production volume significantly impacts the optimal wafer size choice. For low volume production, smaller wafers (3-inch to 6-inch) often provide better economics due to lower per-wafer costs and reduced equipment investment. For production runs of a few hundred to a few thousand devices, the higher efficiency of larger wafers rarely justifies the increased capital expenditure.

For medium volume production, 8-inch (200mm) wafers offer a good balance of cost and efficiency, with mature equipment available at reasonable prices and sufficient throughput for many commercial applications. This "sweet spot" size remains popular for analog devices, power semiconductors, and many specialty components.

For high volume production, 12-inch (300mm) wafers maximize production efficiency for millions of devices, with the economics becoming increasingly favorable as production volume increases. The massive scale of consumer electronics manufacturing makes these larger wafers essential for competitive production of advanced processors, memory, and similar high-volume components.

Technical Specifications Beyond Size

When selecting wafer sizes, several technical specifications must be considered alongside diameter. These specifications affect the wafer's compatibility with processing equipment, its mechanical properties, and ultimately the performance of the devices fabricated on it. Parameters such as thickness, flatness, surface roughness, and crystal orientation all interact with wafer diameter to determine overall suitability for specific applications and processes.

Working with a supplier who can provide detailed technical specifications and guidance is essential for ensuring that your wafers meet all requirements for your specific application. Custom specifications can often be accommodated to address unique project needs. The interrelationship between various wafer parameters means that optimizing one characteristic may require adjustments to others, making expert consultation valuable for achieving the best overall performance.

Thickness Considerations

Wafer thickness varies with diameter and application requirements. Standard thickness generally increases with wafer diameter to maintain mechanical stability during processing. The greater surface area of larger wafers requires proportionally greater thickness to prevent warping and breakage during thermal processing steps.

- 3-inch: 375µm ± 25µm

- 6-inch: 675µm ± 25µm

- 8-inch: 725µm ± 25µm

- 12-inch: 775µm ± 25µm

Thinned wafers are available for applications requiring reduced thickness, such as 3D integration, flexible electronics, or improved thermal performance. These specialized wafers undergo additional processing to reduce thickness while maintaining handling capability.

Double-side polished wafers require specific thickness control for optical applications and devices processed on both sides. The precise parallelism between front and back surfaces is critical for many advanced applications, including photonics and MEMS.

Our 12-inch sapphire wafers are available in various thickness specifications to meet optical and mechanical requirements. The optical quality of these wafers is crucial for applications in LED manufacturing, RF devices, and other specialized fields where sapphire's unique properties are beneficial. The exceptional hardness and optical transparency of sapphire make it ideal for these applications, but also require specialized processing techniques to achieve the precise thickness uniformity and surface quality necessary for high-performance devices.

Surface Finish and Polish

Surface finish requirements vary by application. Prime grade wafers are the highest quality with minimal defects, featuring extremely low particle counts, precise flatness, and excellent surface roughness characteristics. These wafers are essential for advanced lithography processes with critical dimensions below 100nm.

Test grade wafers are acceptable for process development and non-critical applications, offering good quality at lower cost. These wafers may have slightly higher defect densities but remain suitable for many research applications and process qualification runs.

Reclaimed wafers are repolished wafers for cost-sensitive applications, providing significant cost savings while maintaining adequate specifications for many purposes. These environmentally friendly options give wafers a second life after initial use.

Surface roughness is typically specified in angstroms (Å), with prime wafers featuring roughness values below 5Å RMS. This parameter is particularly critical for applications requiring atomic-level surface control, such as epitaxial growth processes.

Crystal Orientation and Dopants

Crystal orientation and doping specifications impact device performance. Common crystal orientations include (100), (111), and (110), each offering different surface properties and etching characteristics. The (100) orientation is standard for most CMOS processes, while (111) may be preferred for specific MEMS applications due to its etching properties.

Dopant type can be P-type (boron, gallium) or N-type (phosphorus, arsenic, antimony) dopants, which determine the majority carrier type and electrical characteristics. The selection impacts threshold voltages, junction depths, and other critical device parameters.

Resistivity range can vary from highly conductive (< 0.001 Ω·cm) to semi-insulating (> 10,000 Ω·cm), with the appropriate range determined by application requirements. RF and high-speed applications often require high-resistivity substrates to minimize parasitic effects.

Dopant uniformity is critical for device consistency across the wafer, with tighter specifications required for larger wafers to maintain yield. Radial and angular variations in dopant concentration can significantly impact device performance uniformity.

Equipment Compatibility Considerations

Ensuring your wafer size is compatible with your processing equipment is essential for successful device fabrication. Different equipment types have specific wafer size capabilities, and using incompatible sizes can lead to processing errors, wafer breakage, or equipment damage. Modern semiconductor fabrication involves dozens of different process tools, each with its own handling system and size limitations that must be considered holistically when selecting wafer specifications.

Before selecting a custom wafer size, inventory all equipment that will be used in the fabrication process and verify compatibility. In some cases, adapters or modifications may be available to accommodate non-standard sizes, but these can affect process reliability and yield. Equipment retrofitting to handle different wafer sizes can be extremely expensive and may introduce process variations that impact device performance, making it preferable to select wafer specifications compatible with existing equipment whenever possible.

Fabrication Equipment Limitations

Different equipment types have specific wafer size capabilities. Lithography systems are optimized for specific wafer sizes, with advanced systems designed exclusively for 300mm wafers. The precise optical systems and alignment mechanisms in these tools are calibrated for particular wafer dimensions and cannot easily accommodate different sizes.

Deposition systems have chamber sizes that limit maximum wafer diameter, with tool configurations optimized for specific wafer dimensions to ensure process uniformity. Gas flow dynamics, plasma distribution, and thermal profiles are all designed around specific wafer geometries.

Etching equipment is designed for specific wafer handling, with etch uniformity optimized for particular wafer sizes. The interaction between wafer size and process parameters such as gas flow patterns and RF field distribution significantly impacts etch uniformity.

Inspection tools are calibrated for particular wafer dimensions, with automated handling systems designed around standard sizes. High-resolution inspection equipment requires precise positioning and movement control that depends on consistent wafer dimensions.

Handling Systems

Wafer handling systems must be compatible with your chosen wafer size. Cassettes and carriers are designed for specific wafer diameters, with precise slot spacing and dimensions that cannot accommodate different sizes. The industry standardization of these carriers ensures compatibility across different tools but restricts flexibility in wafer dimensions.

Robotic handlers are programmed for particular wafer dimensions, with end effectors and movement patterns optimized for specific sizes. The precision required for wafer handling increases with wafer size, as larger wafers are more susceptible to flexing and damage during transport.

Edge grippers are sized for specific wafer thicknesses and diameters, with mechanical designs that cannot easily adapt to different dimensions. The grip force and contact area must be carefully controlled to prevent damage while ensuring secure handling.

Vacuum chucks are designed for particular wafer sizes, with vacuum channel patterns optimized for specific diameters to ensure proper wafer holding during processing. Uniform vacuum distribution becomes increasingly challenging with larger wafer sizes, requiring more sophisticated chuck designs.

Custom Wafer Specifications and Services

For projects requiring non-standard specifications, custom wafer services provide tailored solutions. These services allow researchers and manufacturers to obtain wafers that precisely match their unique requirements, even when these fall outside standard industry offerings. Custom specifications might include unusual diameter-thickness combinations, specific crystal orientations, special doping profiles, or unique surface treatments that aren't readily available as standard products.

Working with a supplier experienced in custom wafer fabrication ensures that your specific needs are met without compromising quality or reliability. Custom solutions may involve special material combinations, unique dimensions, or specialized processing steps. The expertise required for successful custom wafer manufacturing extends beyond standard production capabilities, requiring deep understanding of material properties, processing limitations, and application requirements to deliver specifications that truly meet customer needs.

Custom Diameter Options

While standard diameters are most common, custom sizes can be manufactured for specialized applications. Non-standard diameters are available for specific research or legacy equipment needs, including intermediate sizes like 5-inch or 7-inch wafers that may be required for compatibility with specialized equipment or historical process flows.

Partial wafers (quarter or half wafers) are available for smaller scale projects, providing cost savings while maintaining the same material properties and specifications as full wafers. These options are particularly valuable for research applications with limited material requirements.

Custom shapes such as non-circular substrates are available for specialized applications, including rectangular, square, or custom-shaped wafers for specific device geometries or equipment compatibility requirements.

Custom Processing Services

Beyond basic wafer specifications, custom processing services enhance versatility. Custom doping profiles with tailored dopant types and concentrations, including gradient doping, buried layers, or specialized dopant combinations not available in standard products, can be created. These custom profiles can be essential for optimizing specific device characteristics.

Epitaxial layers with custom epitaxial growth on various substrate types, with precise control of layer thickness, composition, and doping, are available. These epitaxial structures can be designed to exact specifications for particular device requirements.

Specialized coatings such as metal, oxide, or nitride films can be deposited to specification, including unusual materials or multilayer stacks with precisely controlled thicknesses and compositions. These coatings may serve as diffusion barriers, optical filters, or electrical contact layers.

Patterned wafers with pre-patterned features for specialized applications, including alignment marks, test structures, or device-specific geometries that simplify subsequent processing steps, are also available.

At UniversityWafer, we offer silicon carbide wafers with custom specifications, including various diameters, polytypes, and doping levels. These can be tailored to your specific power electronics or high-frequency device requirements, ensuring optimal performance in demanding applications. Our custom SiC wafers are available with different surface finishes, crystal orientations, and micropipe densities to address the precise needs of advanced power devices, RF components, and high-temperature electronics that leverage SiC's exceptional thermal and electrical properties.

Conclusion

Selecting the right wafer size involves balancing technical requirements, economic considerations, and equipment compatibility. By understanding the factors that influence wafer size selection, you can make informed decisions that optimize your semiconductor fabrication process. The ideal wafer size depends on your specific application, production volume, and budget constraints. Careful consideration of all these factors will lead to the most efficient and cost-effective manufacturing solution for your particular needs.

At UniversityWafer, we provide a comprehensive range of wafer materials and sizes to meet diverse application needs. From standard silicon wafers to specialized materials like sapphire and silicon carbide, our inventory supports applications from basic research to advanced device fabrication. Our technical team is available to help you select the optimal wafer specifications for your specific project requirements. With decades of experience serving both academic and industrial customers, we understand the unique challenges of different applications and can provide expert guidance throughout the selection process.

FAQs About Custom Wafer Sizes

Frequently Asked Questions

What is the most cost-effective wafer size for small-scale production?

For small-scale production or research applications, 3-inch to 6-inch wafers typically offer the best balance of cost and usability. These sizes require less expensive processing equipment while providing sufficient area for most prototype and low-volume applications. The per-wafer cost is significantly lower than larger diameters, allowing for more experimental iterations within a fixed budget.

Can I order partial wafers for research projects?

Yes, we offer quarter and half wafers for research projects with limited budget or material requirements. These partial wafers maintain the same specifications as full wafers while reducing costs for smaller-scale experiments. This option is particularly popular among university researchers and startups with constrained budgets who need high-quality materials for proof-of-concept work.

How does wafer size affect device yield?

Larger wafers generally provide more usable dies per wafer, improving overall yield efficiency. However, as wafer size increases, the risk of process variations across the wafer may also increase, potentially affecting uniformity. The optimal size depends on your specific process capabilities and device requirements. Advanced process control techniques become increasingly important with larger wafers to maintain consistent device characteristics from center to edge.

What wafer size is recommended for MEMS applications?

MEMS applications commonly use 6-inch (150mm) or 8-inch (200mm) wafers, which provide a good balance between manufacturing cost and yield. These sizes accommodate the relatively large feature sizes of many MEMS devices while remaining compatible with specialized MEMS fabrication equipment. The mechanical properties and thickness uniformity of these intermediate-sized wafers are well-suited to the precise dimensional control required for successful MEMS fabrication.

Are custom wafer thicknesses available?

Yes, we offer custom wafer thicknesses to meet specific application requirements. Whether you need ultra-thin wafers for 3D integration or thicker substrates for mechanical stability, we can provide silicon and other materials with custom thickness specifications. These non-standard thicknesses can be critical for applications like backside illuminated sensors, stacked die packages, or devices requiring specific thermal characteristics.