Aluminum Nitride X-Ray Diffraction (XRD) Data

- Home

- About Us

- Substrates

- Silicon Wafer

- Silicon Wafer Diameters

- 25.4mm Silicon Wafer

- 50.8mm Silicon Wafer

- 76.2mm Silicon Wafer

- 100mm Silicon Wafer

- 125mm Silicon Wafer

- 150mm Silicon Wafer

- 200mm Silicon Wafer

- 300mm Silicon Wafer

- 450mm Silicon Wafers

- 1 Inch Silicon Wafer

- 2 Inch Silicon Wafer

- 3 Inch Silicon Wafer

- 4 Inch Silicon Wafer

- 5 Inch Silicon Wafer

- 6 Inch Silicon Wafers

- 12 Inch Silicon Wafers

- Silicon Wafer Types

- P-Type Silicon

- N-Type Silicon

- Undoped Silicon

- Float Zone

- Silicon Wafer Flats

- Single Side Polished Silicon Wafers

- Double Side Polished Silicon Wafers

- As-Cut Silicon Wafers

- Lapped Silicon Wafers

- Etched Silicon Wafers

- Low Total Thickness Variation Silicon Wafers

- Porous Silicon

- Thin Film

- Ultra-Flat Silicon Wafers

- Silicon Wafer Grades

- Silicon Wafer Mobility Calculator

- Soft Lithography

- PDMS Micro-fluidic Chip Platforms

- Platinized Silicon Wafer

- Epitaxial Silicon Wafers

- Silicon Wafer Surface Roughness

- Silicon Wafer Uses

- Semiconductor and Related Device Manufacturing

- Gold Coated Silicon Wafers

- X-ray diffraction @ zero background specimen holder

- Diced Silicon Wafers

- Wafer Bonding

- Wafer Preperation

- Wafer Processing

- Polyelectrolyte Multilayer Modified Silicon

- Chemical Mechanical Polishing (CMP)

- Silicon Wafer Microfluidics

- Thinnest Silicon Wafers

- Annual Volume of Silicon Wafer Production

- Plasma Etching Silicon Wafers

- Silicon Wafer Annealing

- Direct Radioactive Nuclide Electricity

- Polycrystalline Silicon

- Substrates 2d Materials

- Zinc Oxide on Silicon

- FTIR Undoped Silicon

- High-Pressure Synthesis Experiments

- Silicon Pillars

- PDMS Microstructures

- Silicon Mirros

- Ar Ion Evaporator Deposited Metal Contacts

- Silicon Ingots

- PTFE

- Silicon Wafer Sorting

- Black Silicon Wafers

- Ultra-Flat Silicon Wafers

- Diced Silicon Wafers

- Silicon Wafer Bonding

- Silicon Wafer Fabrication

- Cleaving Silicon Wafers

- Silicon Wafer Orientation

- Ultra-Thin Silicon Wafers

- Custom Silicon Wafers

- Silicon Wafer Suppliers

- Partical Count

- Silicon Wafer Diameters

- Aluminum

- Glass Wafers

- Fused Silica Wafers

- Gallium Nitride Wafers (GaN)

- Germanium Wafers

- Graphene

- Silicon Carbide (SiC)

- Sapphire (Al2O3) Wafers

- Quartz Single Crystal

- Solar Wafers

- TEOS Oxide

- Silicon on Insulator Wafers

- Thermal Oxide

- Silicon Wafer

- Blog

- Wafer Store

- Contact Us

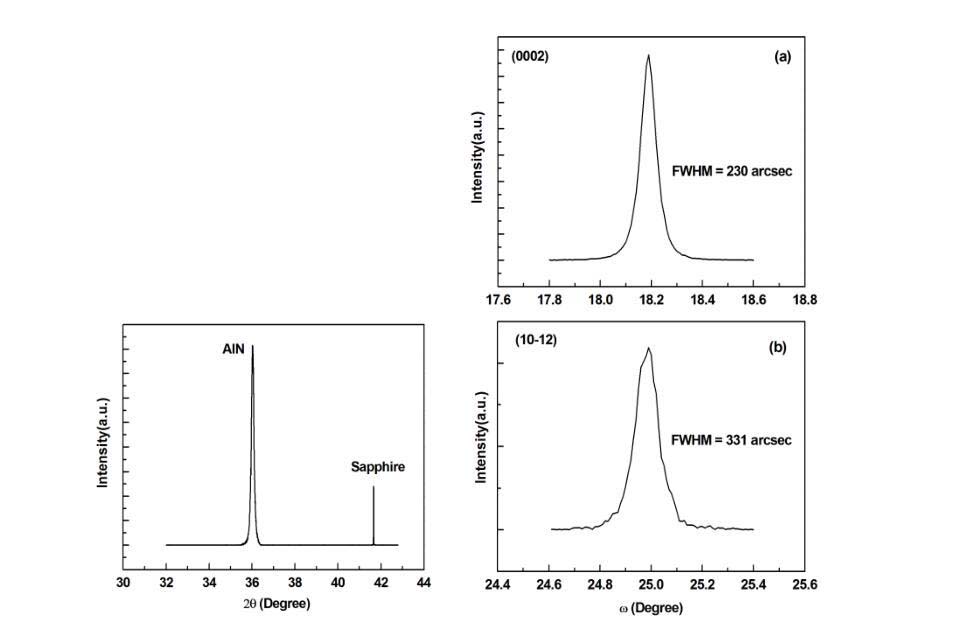

Aluminum on Sapphire X-Ray Diffraction Data

X-ray diffraction (XRD) is a well-known method often used to determine thin layers and crystalline Oris.

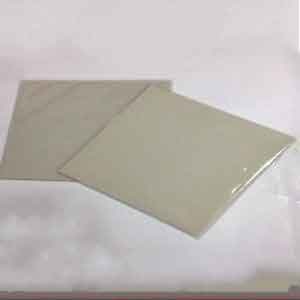

Below are just some of the AlN wafers we have sold.

1. 25 nm AlN/Silicon, 2 inch wafers,qty. 10pcs Fill out form for pricing

2. 25 nm AlN/Sapphire, 2 inch wafers,qty. 10pcs Fill out form for pricing

thicker AlN (> 1 µm) XRD data, like FWHMs of symmetric and skew(or a)symmetric rocking curves? - Pls see attachment

Get Your Quote FAST! Or, Buy Online and Start Your Research Today!

Aluminum Nitride XRay Diffraction Data

Aluminum Nitride XRay Diffraction data are useful in analyzing the structural properties of AlN thin films. They help determine the crystalline quality of the materials. The diffraction peaks of aluminum nitride were measured on Mo/sapphire, Mo/SiO 2 and Si substrates. It was found that the diffraction peak of AlN on Mo/sapphire was much stronger than that of AlN thin film on the SiO 2 sandstone substrate.

XRD measurements of AlN were performed on pure Al at 200-300W power. The pressure  of 1mTorr was selected because it was the best compromise between relative (002) XRD peak intensity and film stress. The 2:1 Ar/N 2 flow ratio was applied to all experiments. The lower pressure was used for sample M15 because of the higher crystalline structure of the material.

of 1mTorr was selected because it was the best compromise between relative (002) XRD peak intensity and film stress. The 2:1 Ar/N 2 flow ratio was applied to all experiments. The lower pressure was used for sample M15 because of the higher crystalline structure of the material.

XRD measurements were performed on single locations on a single sample, which is known as the rocking curve. The sample was fixed at the 2nd peak position and was subsequently shook across the o axis to measure the film's stress. By combining the diffraction data with SEM analysis, the biaxial stress of the film was calculated from XRD measurements.

XRD measurements of AlN were obtained by using a reactive sputtering technique, which was done on a sapphire substrate. The AlN layer was grown with a preferred Ori in the (110) plane. In contrast, Mo layers without AlN depositions were used to measure the diffraction data of AlN. The analysis showed that the two materials were in close proximity to each other and had similar diffraction patterns.

The results from the ALN XRD data were interpreted according to the rocking curve. For instance, the XRD diffraction peak was observed in the region of the sample with the 2nd at the (002) peak position. This result showed that the material had high crystalline structure with low atomic number. The results were analyzed using the diffraction method. Aside from diffraction, the diffraction pattern showed the structural characteristics of AlN.

The ALN XRD data were obtained from a series of measurements. In this study, the Mo electrode was grown on an AlN substrate with the preferred Ori in the (110) plane. The AlN film was grown on AlMo in a different way with the sputtering parameters. The result showed that the Mo films had improved surface roughness compared to pure aluminum. The aluminum films were found to have a better surface roughness.

XRD data of aluminum nitride are important in evaluating the mechanical properties of the material. By using a variety of techniques, the ALN can be analyzed in many different ways. One of these methods is XRD, where the sample is prepared by electrolysis. In another method, the samples are pyrolyzed at different temperatures. The high temperature used for the procedure causes the thin film to decompose.

XRD data are a crucial part of materials analysis. The results obtained from ALN XRD data are used to determine the mechanical properties of the material. The XRD data can also be used to estimate the stress and strain in the material. The diffraction data of aluminum nitride are a great reference for many types of research. This type of diffraction data is a valuable tool for measuring the mechanical properties of the material.

In addition to XRD data, ALN is also useful in determining the strength of the material. The XRD data of aluminum nitride is very sensitive to stresses. It provides the optimum conditions for a material's mechanical performance. A variety of other tests have been performed. The ALN XRD data are an invaluable source of information for researchers. If you're interested in studying the properties of ALN, check out the references below.

XRD data for aluminum nitride can also be used for quality assessment. This is useful for evaluating the quality of the material and determining how the various properties can be optimized. Using the data from aluminum nitride will help you understand the structure of the material. You can determine the crystalline Ori of the material in this way. The atomic structures of this material are very similar to those of the pure metal.

What is the Difference Between Sapphire and Alumina?

When comparing sapphire with alumina, the latter is more durable. Sapphire is one of the hardest natural materials known to mankind and has a high melting point of more than 2000degC. It is also chemically inert, meaning it is resistant to many types of chemicals. Unlike alumina, sapphire has a wide range of colors and transmits ultraviolet, visible, infrared, microwaves, and x-rays.

The difference between alumina and sapphire lies in the process of crystallization. Alumina is a single crystal of alumina and has a uniform Ori. When compared to sapphire, the latter is more resistant to heat than alumina. In addition to the differences between alumina, there are many similarities between the two materials. Artificial sapphire is a synthetic sapphire that is grown under careful control in a lab.

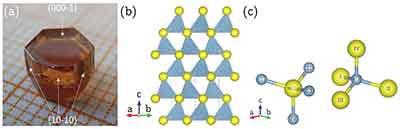

The structure of sapphire is hexagonal, and it belongs to the R3c space group. Its crystalline structure is a single crystalline form of corundum, which is also known as alumina or alpha-alumina. The crystalline structure is formed by intercalating aluminum planes with oxygen planes. In sapphire, two-thirds of the sites are vacant, and its aluminum/oxygen ratio is 2:1. The oxygen atoms have six Al neighbours, while the aluminum atoms are paired with six oxygen atoms. Ultimately, a sapphire can be cut along its rhombohedral planes, which make it cleavable.

What is Aluminum Nitride Used For?

What is aluminum nitride used in? In technical terms, aluminum nitride is the solid nitride  of aluminium. This material is highly thermally conductive and electrically insulating. It has a band gap of approximately six eV at room temperature, which makes it useful in optoelectronics. It is a synthetic material that is produced by carbothermal reduction of aluminium oxide. It requires hot pressing and sintering aids to produce a dense and technically-grade material.

of aluminium. This material is highly thermally conductive and electrically insulating. It has a band gap of approximately six eV at room temperature, which makes it useful in optoelectronics. It is a synthetic material that is produced by carbothermal reduction of aluminium oxide. It requires hot pressing and sintering aids to produce a dense and technically-grade material.

Aluminum nitride is an extremely versatile material, with a high thermal conductivity and electrical insulation. Because of its low coefficient of thermal expansion, it is often used in semiconductors and high-power electronics. While its properties make it suitable for high-power electronic applications, it is also used in a variety of other applications. The following are some common examples of what aluminum nitride is used for.

Aluminum nitride is a type of technical ceramic material. It has excellent electrical insulation and thermal conductivity, making it a suitable medium for a wide range of electrical components. It is also an ideal heat sink, as it has a thermal conductivity similar to silicon. This makes it a staple of the semiconductor industry, but its other uses include LED lighting technology and a variety of other applications.

The most popular application for aluminum nitride is in the Microelectronic industry. Its properties include high thermal conductivity, low thermal coefficient, and electrical insulation. These qualities make it a perfect material for semiconductors. In addition, it is extremely resistant to corrosion and has high thermal shock resistance. It also has a very high sintering temperature. However, it is unstable in hydrogen and carbon dioxide atmospheres. It is not reactive with normal semiconductor processes and will degrade slowly in mineral acid and strong alkalis.

Aluminium nitride is a technical ceramic material that has excellent electrical insulation and thermal conductivity. It is used for high-power electronics, semiconductors, and LED lighting. The properties of aluminum nitride allow it to resist corrosion and to resist extreme temperatures and pressures. There are also a number of other uses for this material, including automotive components, and in aerospace. If you're wondering, what is aluminium nitride, read on.

Aluminium nitride is a thermoplastic material with excellent thermal and electrical insulation. It is also widely used in mobile phones. The high thermal conductivity of aluminum nitride makes it an excellent material for various applications. It is also a popular material in aerospace and medical industries. Its use is limited only by its availability and its low cost. It is not suitable for use in high-temperature electronics.

The high-purity aluminum nitride powder has excellent electrical insulation properties and thermal conductivity. This material is used in high-speed radios, cellular phones, and semiconductors. It is a stable, lightweight material that can withstand extremely high temperatures. Despite its high thermal and electrical resistance, it can be corrosive, which makes it a desirable material for electronic devices.

Aluminium nitride has high thermal and electrical conductivity and is used for a variety of different applications. It is commonly used in mobile phones as an RF filter. It is also used in aerospace and military applications as a piezoelectric material. Its high electrical resistivity makes it an excellent material for a variety of aerospace and military applications. Although it is toxic, it is safe for people and is a good choice for many industries.

Aside from aerospace applications, it is also used in electronics and power semiconductors. Its high thermal and electrical properties make it an excellent choice for a wide range of applications. It also offers good electrical insulation, making it suitable for a variety of extreme environments. If you're unsure about what aluminum nitride is, you can always start by reading about the properties and advantages of this material.

Aluminum nitride is a ceramic with a high coefficient of thermal expansion. Its properties make it a perfect material for conductive and non-conductive applications. This makes it the ideal material for heating and cooling equipment. This material also has excellent chemical resistance. It's widely used in aerospace and military applications. There are several other uses for aluminum nitride. The benefits of this compound are many.

What is AlN X-Ray Diffraction (XRD)?

In extreme cases where no other reflections are present in the XRD data, the preferred Ori of the TC reaches the maximum value of n. This position corresponds to the pressure load of the powder data at 36.04 degrees on the film. The observed RD peaks can be assigned to either Wurtzite or AlN, but not to both. [Sources: 3, 5]

The discrepancy in the actual size shows, however, that the grains on the film surface may not be entirely made of AlN, which contains an oxide shell that cannot be examined in the X-ray image. The average grain size obtained from the X-ray diffraction data for Wurtzite and Aln is also consistent with the actual grain size of the powder data and the grain-to-film ratio. [Sources: 0]

X-ray and neutron diffraction we investigate the properties of amorphous Al2O3 samples produced by anodic oxidation of aluminium foil. X-rays and neutrons of the samples and examine their properties by X-ray, neutron and electron microscopy. X-rays and neutron diffractors, but also by using a high-resolution electron microscope. [Sources: 7]

A microstructural analysis of the grazing angle and the swing curve of the Al2O3 samples is performed. With X-ray and neutron diffraction, the Obob gives us a high-resolution image of a rock with an angle of 1.5 degrees, in order to determine the shape and structure of its surface and its structural properties. [Sources: 5]

The rock shows a widening of the Raman peak, which is explained by the presence of a large amount of carbon dioxide (CO 2) in the Aln, as shown in d. It is clear that there is a good correlation between the simulated and experimental data, as Fig. 8 (b) shows spectro- scopic ellipsometry data for a simulated curve with samples produced at 400 degrees Celsius (Fig. 8 (b)). A much smaller sample (d) of alN is observed and shown as a red dot with a high resolution X-ray and neutron diffraction image. [Sources: 2, 5, 8]

The J cm2 sample (B) has two diffraction peaks (33 ° C and 36 ° C), which correspond to the aln 100 and 002 Oris. The 2nd XRD peak is used to measure the grating constant of the AlGaN layer at different surface alignments, as shown in the image from Fig. 1. Since the Al GaN layers studied here are measured differently, they can also be calculated by measuring the difference between their surface Ori and the X-ray and neutron peaks. A film was made with the same material as in Table 1, but with a slightly different Ori (e.g. 100 degrees). [Sources: 2, 4]

The J cm2 sample (A) is indicated as implanted or annealed, and the X-ray and neutron tips of the AlGaN layer in different Oris. The sample has been implanted, but is not shown in the figure below (Fig. 1), as it has not yet been implanted and annesced. [Sources: 7]

The BET technique was used for structural analysis of the sample, and abstract copper alumina had Nbsp instrumental analysis in XRD, SEM and EDS. The BET techniques were used in the structural study of this sample and abstract copper-alumina was analyzed in both RD and SEM using an NSPI instrument, but not in E DS. [Sources: 7]

The microstructure of sintered composites was characterized by the use of NSPI instruments and Nbsp instrumental analysis in XRD, SEM and EDS. [Sources: 6]

To describe the crystal structure of the samples in detail, we measured the rock curve of each sample as shown in Figure 3. The Raman spectrum of these samples was measured to detect the presence of a high degree of scattering, or "Raman scattering," in the Aln foil. These results suggest that ramen scattering is a viable method to detect the structure of sintered composites, especially those with large numbers of nanoscale crystals. Aln films produced by PLD to study the chemical composition and properties of AlN films in a variety of materials were measured in XRD, SEM and EDS. [Sources: 2]

The X-ray examination was performed at a strip angle of 1.5 degrees with a TFT equipped with an X-ray spectrometer (X-ray spectrometer) and a high-resolution XR - RTIR (X-ray spectrometry). The T FT worked in N-type depletion mode, indicating that AlN films grown in RT had electron conduction channels, even at a gate bias of zero volts. The estimated band gap of the Aln films at 0.21 n / m2 (0 - 79% Al) is 0.82%, and the deposited films were shown preferentially at 002% and were in line with the RD and FTIR results. [Sources: 1, 5]

Sources:

[0]: https://onlinelibrary.wiley.com/doi/full/10.1002/pssb.201900400

[1]: https://www.x-mol.com/paperRedirect/5648956

[2]: https://www.hindawi.com/journals/jspec/2013/103602/

[3]: https://aip.scitation.org/doi/10.1063/5.0011331

[4]: https://www.nature.com/articles/s41598-019-52067-y

[5]: https://cyberleninka.org/article/n/1263142

[6]: http://profile-football.com/kbuiexqix/zro2-powder.html

[7]: http://storeew.pondybiz.com/eof25r/al2o3-structure.html

[8]: https://journals.sagepub.com/doi/full/10.1177/096369351802700601