I dont have precise requirements for these specifications. I’ll glue the chips to silicon wafers for etch tests anyway. It would be cool to have 4 inch wafers as carriers for etching tests, to see how an etching process would behave on a full wafer. Quote: 10 wafers optical grade, X Cut.

Lithium Tantalate (LiTaO3) for Research and Production

100mm LiTaO3 Substrates Used for Etching Tests

An associate professor researching Si3N4-based nonlinear integrated photonics requested the following quote:

Reference #304096 for specs and pricing.

Get Your FAST! Or, Buy Online and Start Researching Today!

Lithium Tantalate (LiTaO3) Wafers in stock:

- LiTaO3 optical grade, X-cut, 10x10x0.5mm, DSP

- LiTaO3 saw grade, X-cut, 10x10x0.5mm, SSP

- LiTaO3 saw grade, X-cut, 3" Dia x 0.5mm wafer, SSP

- LiTaO3 optical grade, Y-cut, 10x10x0.5 mm, DSP

- LiTaO3 saw grade, Y-cut, 10x10x0.5mm, SSP

- LiTaO3 Saw grade, Y-cut wafer with 128 degree off , 3" dia x0.5 mm , SSP-1

- LiTaO3 Saw grade, Y-cut wafer with 36 degree off , 2" dia x0.5 mm , SSP-1

- LiTaO3 Saw grade, Y-cut wafer with 36 degree off , 3" dia x0.4 mm , SSP

- LiTaO3 Saw grade, Y-cut wafer with 36 degree off , 4" dia x0.35 mm , SSP

- LiTaO3 Saw grade, Z-cut, 10x10x0.5 mm, SSP

- LiTaO3 optical grade, Z-cut, 10x10x0.25 mm, DSP

- LiTaO3 optical grade, Z-cut, 10x10x0.5 mm, DSP

- LiTaO3 optical grade, Z-cut, 10x10x1.0 mm, DSP

- LiTaO3 optical grade, Z-cut wafer, 2" Dia x 0.5mm , DSP

- LiTaO3 optical grade, Z-cut wafer, 3" Dia x 0.5mm , DSP

- LiTaO3 saw grade, Z-cut, 3"Dia x0.5mm wafer, SSP

🧪 Lithium Tantalate (LiTaO₃) Wafers for Photonics, SAW, and MEMS Applications

UniversityWafer, Inc. offers high-quality Lithium Tantalate (LiTaO₃) wafers in a variety of orientations, cuts, and specifications for researchers and commercial device manufacturers. LiTaO₃ is widely used in acousto-optic, piezoelectric, and electro-optic applications due to its exceptional crystal and dielectric properties.

🔍 Available Specifications

| Property | Options & Values |

|---|---|

| Orientation | X-cut, Y-cut, Z-cut, 36° Y-cut, 128° Y-cut |

| Diameter | 2", 3", 4", 6" |

| Thickness | 200 µm – 1000 µm |

| Polish | Single or Double Side Polished (SSP/DSP) |

| Surface Roughness | < 1 nm Ra (DSP available for optical-grade applications) |

| Material Type | Congruent or Near-Stoichiometric |

| Resistivity | High-resistivity dielectric substrate |

| Crystal Type | Single-crystal, Y/LT grown |

| Usage | Epi-ready, SAW-ready, optical-quality |

📦 Custom specs available on request – fast lead times and academic discounts offered.

🔬 Key Features of LiTaO₃ Wafers

-

High thermal and mechanical stability

-

Excellent piezoelectric coupling (ideal for SAW/BAW devices)

-

Low dielectric loss and broad optical transmission range

-

Strong nonlinear optical behavior for harmonic generation

-

Ideal for MEMS resonators, electro-optic switches, and IR detectors

⚙️ Common Applications

-

📱 RF Filters: Used in smartphones, 5G, and WiFi SAW/BAW devices.

-

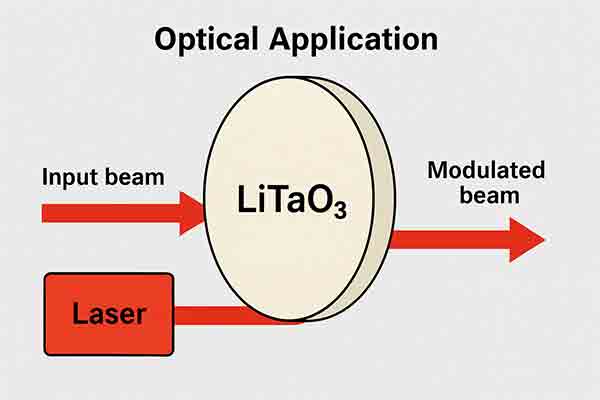

💡 Electro-Optic Modulators: Telecom-grade modulators and Pockels cells.

-

🔁 Frequency Converters: SHG and THG in nonlinear optics.

-

📷 Pyroelectric IR Sensors: Thermal and motion detection.

-

⚙️ MEMS/NEMS: Piezo-actuators, resonators, and gyroscopes.

🏭 Why Order From UniversityWafer, Inc.?

-

✅ ISO and RoHS compliant partner fabs

-

✅ Academic and volume discounts

-

✅ Quick turnaround and global delivery

-

✅ Technical support for device R&D

Lithium Tantalate (LiTaO3) Wafers for Research and Production

LiTaO3 is a perovskite with unique optical properties.

Used in:

- Non-linear Optics

- Passive infrared sensors

- Motion detectors

- Terahertz generation and detection

- Surface acoustic wave applications

- Cell phones

- Pyroelectric nuclear fusion

Please let us know what specs and quantity you would like us to quote?

What are Lithium Tantalate (LiTaO3) Substrates Used For?

Lithium Tantalate (LiTaO₃) is a ferroelectric and piezoelectric single-crystal material that’s widely used in optoelectronic, photonic, and RF (radio frequency) semiconductor devices due to its unique electro-optic, acousto-optic, piezoelectric, and nonlinear optical properties.

🔬 Material Properties of LiTaO₃

| Property | Value / Description |

|---|---|

| Crystal system | Trigonal (R3c space group) |

| Melting point | ~1650 °C |

| Transparency range | 0.25–5.5 µm (UV to mid-IR) |

| Dielectric constant (ε) | ~43 along z-axis |

| Electro-optic coefficient | High (used in modulators and Pockels cells) |

| Piezoelectric coefficient | Strong (used in SAW and BAW filters) |

| Coercive field | Lower than LiNbO₃ (good for stable ferroelectric behavior) |

⚙️ Semiconductor & Device Applications

Lithium Tantalate is not a "semiconductor" in the conventional sense (like silicon or GaN), but it's a critical substrate and functional material in many semiconductor-adjacent technologies.

📡 1. RF Filters (SAW & BAW Devices)

-

SAW (Surface Acoustic Wave) and BAW (Bulk Acoustic Wave) filters for mobile phones, IoT, and 5G.

-

Excellent for high-frequency signal filtering due to low acoustic losses.

-

Z-cut and 36° Y-cut LiTaO₃ are popular in SAW applications.

🔁 2. Electro-Optic Modulators

-

Pockels effect in LiTaO₃ allows high-speed modulation of light.

-

Used in fiber optic telecom and Q-switching in lasers.

💡 3. Nonlinear Optical Devices

-

Used for frequency doubling (e.g., 1064 nm → 532 nm).

-

Less prone to photorefractive damage than LiNbO₃ at higher power levels.

🧠 4. Pyroelectric and Infrared Sensors

-

Converts IR radiation into an electrical signal.

-

Used in motion detectors, thermal cameras, and spectroscopy.

🧬 5. Thin Film Piezoelectric Layers (in MEMS)

-

Used in MEMS actuators, gyroscopes, and sensors.

-

Thin films of LiTaO₃ are being explored for integration on CMOS-compatible platforms.

🔄 Comparison with Lithium Niobate (LiNbO₃)

| Feature | LiTaO₃ | LiNbO₃ |

|---|---|---|

| Electro-optic effect | Lower than LiNbO₃ | Higher |

| Piezoelectricity | Better for SAW due to higher stability | More prone to photorefractive damage |

| Thermal stability | Higher | Lower |

🧩 Common Substrate Forms

-

X-cut, Y-cut, and Z-cut wafers: orientation defines acoustic and optical properties.

-

Standard wafer sizes: 2"–6", polished or double-side polished, epi-ready available.

🛠️ Industry Use Cases

-

Telecom: RF front-end filters in smartphones (especially LiTaO₃ SAW filters).

-

Defense & Aerospace: Optical modulators and IR sensors.

-

Photonics research: Nonlinear optical generation and quantum optics.

-

Consumer electronics: Motion and IR detection in security systems.