Do you also have ITO deposited glass and FTO deposited glass?

If yes, I need 1/2 inch by 1/2 inch around 500 pieces.

Fluorine-doped Tin Oxide (FTO) Substrate

FTO Deposited Glass Wafers

A postdoc requested a quote for the follwoing.

UniversityWafer, Inc. Quoted:

FTO Glass Substrate (TEC 15) 1" x 1" x 2.2 mm, R:12-14 ohm/sq

ITO Coated Glass Substrate 10mm x 10 mm x 0.7 mm, R:9-15 ohm/sq,Nominal ITO film thickness: 180 nm

Reference #139874 for specs and pricing.

FTO Conductive Transparent Substrates

A PhD candidate requested a quote for the following.

The dimensions don't really matter to me. I just need conductive, transparent substrates that will be diced into pieces ranging from 1cm x 1cm to approx. 1" x 2". The thickness is not really important either, just thick enough that they can be handled easily without breaking, maybe around 1 mm. It

It doesn't specifically have to be ITO/FTO as I specified, it just needs to be high conductivity, highly transparent and be chemically stable in mild acid and base solutions for durations of up to maybe a day.

Reference #103101 for specs and pricing.

Get Your FAST! Or, Buy Online and Start Researching Today!

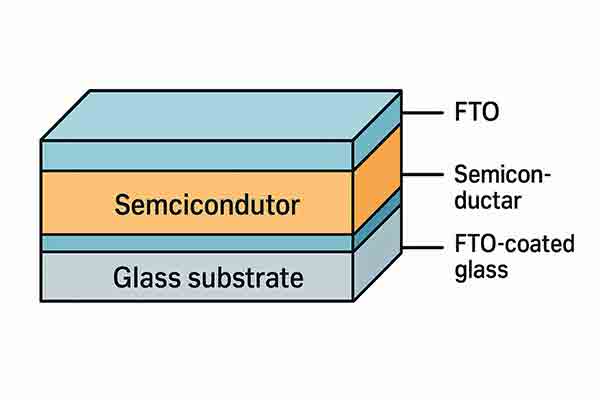

What are FTO Substrates and What are its Semiconductor Applications?

FTO Substrates refer to Fluorine-doped Tin Oxide coated glass.

-

FTO stands for Fluorine-doped Tin Oxide (SnO₂:F).

-

It’s a transparent conducting oxide (TCO) — meaning it allows light to pass through while also

conducting electricity.

conducting electricity. -

Typically, it’s a thin film of tin oxide (SnO₂) that's doped (i.e., intentionally modified) with a small amount of fluorine to improve its electrical conductivity without significantly sacrificing transparency.

- The substrate usually refers to the underlying material — most often glass, sometimes plastic or other surfaces.

Why FTO is special:

-

It’s highly transparent (~80% or more in visible range).

-

It’s chemically stable (better than Indium Tin Oxide, or ITO, in harsh conditions).

-

It’s conductive with relatively low sheet resistance (typical: 10–20 ohms/sq).

-

It tolerates high processing temperatures (>500°C), which is important for certain semiconductor fabrication steps.

Applications of FTO Substrates in Semiconductors:

| Application | Role of FTO Substrate | Why FTO is used | Image |

|---|---|---|---|

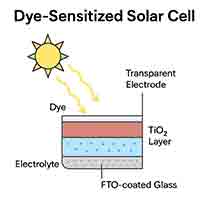

| Solar cells (Dye-Sensitized Solar Cells, DSSCs) | Acts as the transparent electrode where photoelectric conversion happens. | High transparency + electrical conductivity. |  |

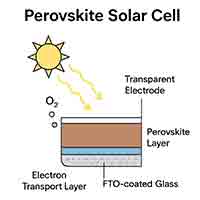

| Perovskite Solar Cells | Front electrode and sometimes as a bottom substrate for spin-coating layers. | Stability against halides and processing temperatures. |  |

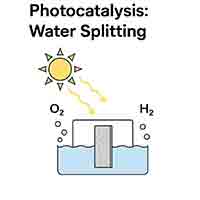

| Photocatalysis (e.g., water splitting) | Conductive support for photocatalyst layers like TiO₂. | Chemically stable in aqueous and oxidative environments. |  |

| Electrochromic devices (smart windows) | Conductive layer where voltage changes optical properties. | Durability under cycling. |  |

| Sensors | Base layer for biosensors, gas sensors, etc., for electrochemical or photoelectrochemical detection. | Good combination of transparency, conductivity, and chemical inertness. |  |

| OLEDs / Displays | Alternative transparent anode in displays when stability matters. | When stability is more critical than conductivity. |  |

Quick real-world example:

In a dye-sensitized solar cell, you have a sandwich structure:

Glass → FTO → TiO₂ layer → Dye → Electrolyte → Counter electrode

Here, the FTO provides both the light entrance path and the electric contact to collect generated charges.