Two-Step Photolithography

A PhD candidate requested a quote for the following.

I am using these silicon wafers in a two step photolithography process, I dont believe the dopant or resistivity will effect this process, but if you have any experience in this process any suggestions for dopant would be fine.

4 Inch P(100) 500um SSP

UniversityWafer, Inc. Quoted:

Si Item #452 - 100mm P(100) 0-100 ohm-cm SSP 500um

Reference #102246 for specs and pricing.

Get Your FAST! Or, Buy Online and Start Researching Today!

Photolithography Process to Etch Quartz Wafers

A research scientist requested a quote for the following.

We have new project that study the best temperature coefficient for small SMD TF, we will use photolithography process to etch the quartz.

The quartz wafer size is not so critical (due to the budget cost is a sensitive factor in this project). The thickness is 0.1mm and DSP.

I have no idea of the cutting angle for achieving the best temperature coefficient. In traditional method, the cutting angle is 2degree at X or Y axis.

Do U have idea? I need the min. qty.

Any available size for selection?

UniversityWafer Quoted:

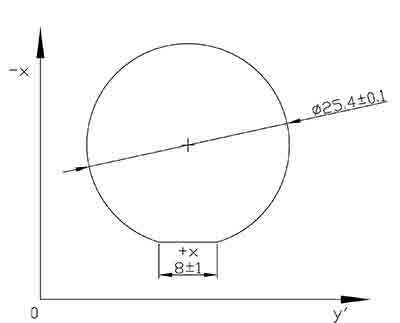

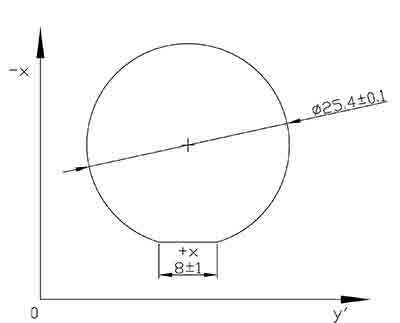

Item #U01-130301-2

25.4mm z-+/-2 deg cut 0.10mm DSP SAW Grade Seedless Single Crystal Quartz

Reference #147879 for specs and pricing.

Through-Etch Photolithography Process

A graduate student studying mechanical engineering department requested a quote for the following.

I am writing this email for asking quotation of wafer but I have no idea which one would be good for my research.. (This is my first time to order wafers) I would like to do photolithography process with the wafer, more specifically, through-etch process. I think ~500um thick wafer would be good. Also, the size, I need 4 inch diameter wafer without any doping. I’ll use the final process from the wafer as gas channel.. Could you please tell me if there is any other concerns for my case? Also, if you have proper ones, please send me the quotation.

Reference #199865 for specs and pricing.

Copper Coated Silicon Wafers for Photolithography

A postdoc requested a quote for the following.

I am looking for copper wafer, 3'' diameter and 1-2mm thickness.

We are doing heat transfer experiment and

we want to use some high heat transfer coefficient material, such as copper, as substrate to fabricate some special device.

We will do photolithography process on the copper wafer, so we want the copper surface to be extremely flat and smooth.

If you have some similar product, could you please provide a quote? We may need 5-10 pieces of it.

If you do not have this product, any related advice will be helpful.

Reference #139968 for specs and pricing.

What is the Photolithography Process?

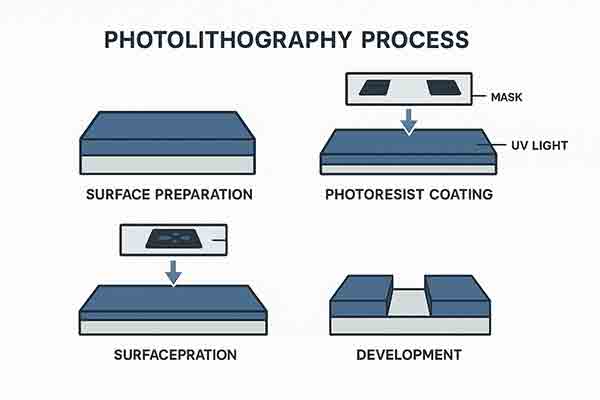

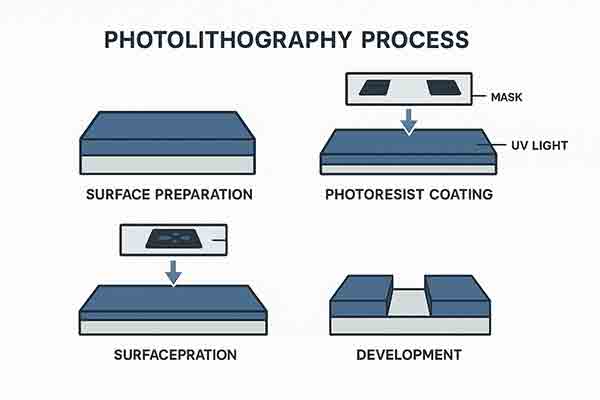

The photolithography process is a critical step in semiconductor manufacturing, used to transfer geometric patterns onto a substrate—usually a silicon wafer—to define micro- and nanoscale features for integrated circuits, MEMS devices, and other microfabricated structures.

🧠 Definition

Photolithography is a light-based patterning process that uses a photoresist material, which changes its chemical properties when exposed to ultraviolet (UV) light. This process enables precise etching or doping of semiconductor materials.

🔬 Steps in the Photolithography Process

1. Surface Preparation

-

Clean the wafer to remove any particles or organic residues.

-

A dehydration bake may be applied to improve resist adhesion.

-

A layer of adhesion promoter (e.g., HMDS) is often applied.

2. Photoresist Coating

-

A liquid photoresist (light-sensitive material) is applied to the wafer surface via spin coating.

-

Spin speeds and viscosity control thickness (typically 0.5–2 microns).

-

A soft bake removes solvent from the resist.

3. Mask Alignment and Exposure

4. Post-Exposure Bake (PEB)

5. Development

-

The wafer is developed using a developer solution, which washes away the soluble photoresist.

-

This reveals the desired pattern on the wafer.

6. Hard Bake

7. Etching or Ion Implantation

8. Photoresist Removal

-

After processing, the resist is stripped (e.g., via ashing or solvents), leaving the desired features on the wafer.

📏 Resolution and Limitations

-

Resolution depends on wavelength of light and numerical aperture of the optics:

Resolution∝λNA\text{Resolution} \propto \frac{\lambda}{NA} Resolution ∝ NA λ

-

Techniques like deep UV (DUV), extreme UV (EUV), immersion lithography, and multi-patterning improve feature size limits.

🏭 Applications

Photolithography Equipment (Spin Coater and Mask Aligner)

A lab manager from a public university requested help with the following.

We're planning to set up a laboratory at the university for manufacturing integrated circuits (ICs) in CMOS technology. The idea is for undergraduates and postgraduates to be able to complete their projects, or parts of them, from start to finish without relying on the charity of local manufacturers. A colleague and I are overseeing the project, and we already have a space reserved and initial funds available, which is a great start.

We need almost everything. Here’s a list I've compiled of the main items we require, which I will attach to the dossier. I don’t think I’ve forgotten anything, but if I have, please let me know.

- Tube Furnace: Necessary for oxidizing wafers and heat treatments. It is important to have precise temperature control to guarantee the quality of the oxide layers.

- Photolithography Equipment (Spin Coater and Mask Aligner): For applying and aligning the photoresist layers, which are essential in the photolithography process to define the IC patterns on the wafer.

- Vacuum Chamber for Vapor Deposition (PVD or CVD): For the deposition of metal or oxide layers. Ideally, the system should be compact enough to fit on a bench and allow for precise depositions.

- Wet Benches: Specific work areas for the wet etching process, where chemical etchings are carried out. These bench systems enhance safety and the handling of chemical products.

- Manual Bonding Machine (Wire Bonder): Equipment for making bond wire connections between the IC and the encapsulation terminals. This equipment helps ensure safer and more reliable connections on a small scale. I won’t let my students suffer so much.

- Encapsulation and Resin Suppliers: Needed to encapsulate and protect the finished ICs. Ideally, we are looking for quality epoxy resins or silicones for small production runs.

- Precision Position: Tools for handling wafers and encapsulated chips, essential for avoiding damage during processes.

- Other universities have already donated some second-hand materials to me, such as analyzers and microscopes. However, for these items, we'll have to purchase or find new donors.

If you can help me, I would greatly appreciate it, as it’s a lot of work, but I really want to bring this opportunity to my students. I lived in London for a while, and a lab colleague strongly recommended you for the wafers, mentioning that you are a fantastic resource in this regard.

Reference #316902 for specs and pricing.