I’m looking for a small quantity of Silicon wafers with thick PECVD oxide on them. Thermal oxide could also serve the purpose. We would like the wafer(s) to be intrinsic FZ if available. We’re looking for 1-3 100mm wafers or 5-10 50.8mm wafers, depending on price. Could you quote us a price and lead time?

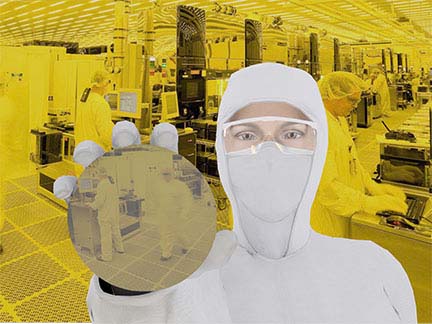

PECVD Oxide on Silicon Wafers

PECVD Coated Silicon Wafers

A PhD in materials science requested a quote for the following.

Reference #320434 for specs and pricing.

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

What is PECVD Oxide on Silicon Wafers and what are they used for?

PECVD Oxide on Silicon Wafers refers to a thin layer of silicon dioxide (SiO₂) deposited on a silicon wafer using Plasma-Enhanced Chemical Vapor Deposition (PECVD). This is a common technique in the semiconductor, MEMS, and microelectronics industries.

What is PECVD Oxide?

PECVD is a low-temperature deposition process that uses plasma energy to enhance chemical reactions, allowing for the formation of silicon dioxide (SiO₂) films on silicon wafers. The process typically involves the following gases:

- Silane (SiH₄) – Source of silicon.

- Nitrous oxide (N₂O) or Oxygen (O₂) – Oxidizing agents.

The chemical reaction is plasma-enhanced, enabling oxide deposition at relatively low temperatures (150-400°C), compared to Thermal Oxide processes, which require much higher temperatures (~900-1200°C).

Properties of PECVD Oxide:

- Low-temperature deposition – Suitable for temperature-sensitive substrates and devices.

- Good step coverage – Conforms well to non-planar surfaces.

- Faster deposition rate compared to thermal oxidation.

- Lower density and higher hydrogen content compared to thermal oxide, which can lead to slightly lower film quality.

- Can be deposited on various materials, not just silicon.

Uses of PECVD Oxide on Silicon Wafers:

1. Dielectric Layer / Insulation:

- Acts as an insulator in semiconductor devices, microelectromechanical systems (MEMS), and integrated circuits (ICs).

- Electrical isolation between different metal layers in multi-level interconnects.

2. Passivation Layer:

- Protects devices from contaminants, moisture, and mechanical damage.

- Reduces surface recombination in solar cells and other optoelectronic devices.

3. Masking Layer for Etching:

- Used as a masking layer during etching processes (e.g., dry etching, wet etching).

- Provides a barrier to prevent etching of underlying silicon.

4. Surface Planarization:

- Helps smooth the wafer surface for subsequent photolithography and device fabrication steps.

5. Optical Applications:

- As an anti-reflective coating or part of multi-layer dielectric stacks in photonic and optoelectronic devices.

6. MEMS and Microfluidics:

- Structural and protective layers in MEMS devices.

- Insulating layer in microfluidic channels.

7. Stress Control:

- Can be tuned to reduce or introduce stress in thin films, depending on the deposition conditions (e.g., gas flow ratios, power levels).

Why Choose PECVD Oxide over Thermal Oxide?

| Feature | PECVD Oxide | Thermal Oxide |

|---|---|---|

| Deposition Temp. | Low (150-400°C) | High (900-1200°C) |

| Deposition Rate | Fast | Slow |

| Conformality | Good | Excellent |

| Film Density | Lower | High |

| Electrical Quality | Moderate | Excellent |

| Applications | Passivation, insulation, MEMS | Gate oxide, high-quality dielectric |

PECVD is preferred when low temperature processing is critical, such as in MEMS, microelectronics, or when other temperature-sensitive materials are already on the wafer.

PECVD Oxide on Silicon Wafers

We have a large selection of silicon wafer diameters with PECVD oxide deposited on them.

Please send us your specs for an immediate quote!