JGS3 Fused Silica Wafers Full Spectrum

Where Can I Buy Infrared Optical Glass JGS3 Fused Silica Substrates?

JGS3 in stock items can be purchased online.

Glass is a common optical material, but it has a high OH content which can distort the image.

Problem: Glasses have a high OH content which can distort the image. This makes them unsuitable for many optical applications.

Solution: JGS3 Fused Silica is one of the most commonly used optical materials due to its low OH content. It is suitable for optical applications due to its low OH-content, and it is extremely transparent in the visible and ultraviolet spectrums. Its excellent bending resistance to shock and temperature make it an excellent material for photovoltaics and solar cells.

Get Your JGS3 Fused Silica Quote FAST!

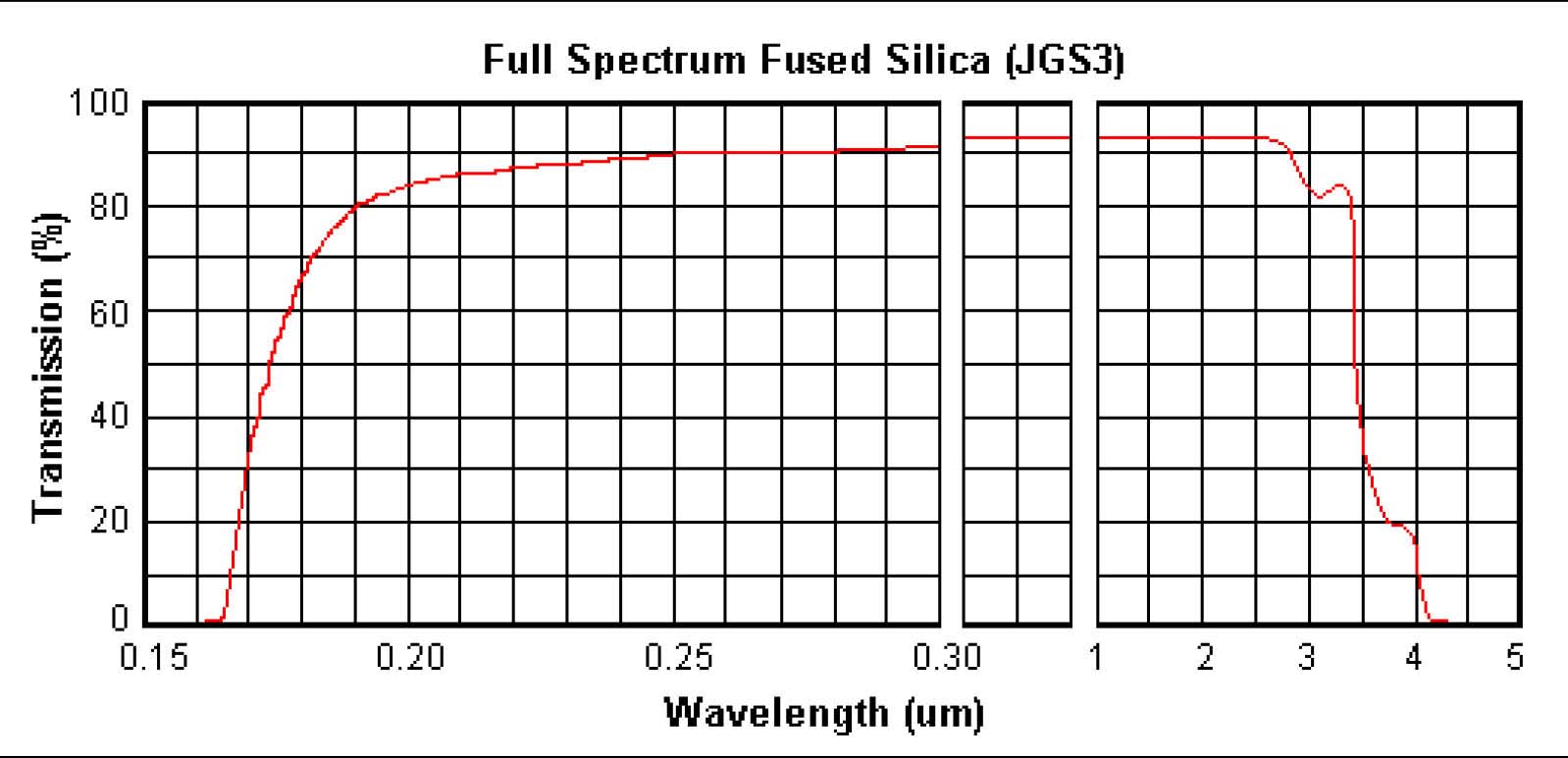

JGS3 Fused Silica Transmission Curve

What Is JGS3 Fused Silica Used For?

JGS3 Fused Silica is one of the most commonly used optical materials due to its high transparency and low OH content. It is suitable for optical applications due to its high OH-content, and it is extremely transparent in the visible and ultraviolet spectrums. Its excellent bending resistance to shock and temperature make it an excellent material for photovoltaics and solar cells.

Due to its outstanding physical and chemical properties, JGS3 Fused Silica is an excellent choice for optical applications. The low OH content and low inclusion and bubble content make it an attractive material for high-end optics. Its low OH content makes it suitable for a wide range of electronic components. Its excellent thermal and radiation resistance make it a good candidate for a variety of applications.

The highest grade of JGS3 Fused Silica is used in optical applications. Its high transparency and low OH content make it an excellent choice for these applications. Because of its spectral range, JGS3 is very chemical and thermal shock resistant. It is also very hard and resistant to abrasion. In addition, it is highly compatible with various electronic components. Its high quality also makes it a popular choice for high-end optical systems.

Fused Silica is the glassy form of quartz. It is tough and hard and has a very low expansion. It is known for its use in wristwatches and electronic systems. Its high IR absorption makes it a good material for optical components. And thanks to advances in raw material beneficiation, it can even be transparent. It is used for a variety of high-performance applications.

What are 5 JGS3 Fused Silica Substrate Applications?

JGS3 fused silica substrates have a range of applications due to their excellent optical and thermal properties. Here are five common applications:

-

Laser optics: JGS3 substrates are used in high-power laser applications due to their ability to withstand high temperatures and their low coefficient of thermal expansion, which ensures stability and accuracy in laser optics.

-

Optical filters: JGS3 is an excellent material for producing optical filters, due to its high optical transmission in the ultraviolet, visible, and infrared regions.

-

Semiconductor processing: JGS3 substrates are used in the manufacturing of semiconductor devices because of their ability to withstand high temperatures and their low thermal expansion coefficient. They are also used as a substrate material in the deposition of thin films.

-

UV lithography: JGS3 substrates are used in the semiconductor industry for UV lithography applications due to their high transmission in the UV region, which enables high-resolution imaging.

-

Biomedical applications: JGS3 substrates are used in various biomedical applications such as microscopy, spectroscopy, and imaging due to their high transparency in the ultraviolet, visible, and near-infrared regions. They are also biocompatible and can withstand sterilization processes.

What Does JGS3 Full Spectrum Fused Silica Mean?

When you need a substrate that can handle very high temperatures and work as an insulator in semiconductors, then JGS2 Grade Fused Silica Wafers is the right choice.

JGS3 windows are fabricated with very high-purity sand in a vacuum pressure furnace, also called electrofusion method. JGS3 has a transmittance over 85% and its application range is in the 260-3500 nm range of optical materials.

| Parameter Value | JGS3 |

| Max Size | <200mm |

| Tramission Range (medium transmission ratio) | 0.185~3.50um (Tavg>85%) |

| OH-Content | 5ppm |

| Fluorescence (ex 254nm) | Strong v-b |

| Impurity Content | 40-50 ppm |

| Birefringent constant | 4-10 nm/cm |

| Melting Method | Electrical Method |

What other Fused Silica Wafer Grades are Available?

Other fused silica wafer grades and their applications include:

What is JGS3 Fused Silica?

JGS3 Fused Silica is an insulating glass that possesses excellent optical properties in the ultraviolet and visible spectral ranges. Its high OH-concentration causes absorption bands that range from 1.2 to 1.5 mm. It is highly transparent in the IR and deep UV spectral regions. However, it is more expensive than Silicon and Calcium Fluoride. Its optical properties are similar to those of ZnS Multi-spectral grade and Heraeus Suprasil 300.

As a result of its high OH-content, JGS1 wafers have very high transparency and a wide spectral range. It is also chemically resistant and can withstand temperature changes up to 1000 degrees Celsius without cracking. In addition, JGS3 is extremely durable and has excellent optical properties, including design compressive strength. It is more resistant to chemical and heat shocks than other types of glass.

JGS3 Fused Silica is made from naturally occurring crystal quartz. It is produced using an electric vacuum furnace, which provides a low water content of less than 5 parts per million. The low inclusion, bubble, and striae content make it ideal for optics. The material is also non-hygroscopic and thermal shock resistant. It is extremely hard and is therefore a superior choice for optical applications.

The advantages of JGS3 Fused Silica are vast. Its high transparency is unmatched, and it has low OH content. It is also suitable for high-temperature applications. Its low OH-content makes it a highly versatile material. It has exceptional transparency in the ultraviolet and visible ranges. Further, its high OH-content makes it a good candidate for optical components. It can also be used in photovoltaic and solar cells.

The highest quality JGS3 Fused Silica is the best material for optical applications. Its high transparency is the hallmark of high-end optics. Its low OH content makes it highly attractive to manufacturers and consumers. Its good thermal and radiation resistance makes it a popular choice for many other applications. In addition, it's compatible with a variety of electronic components. Regardless of its application, JGS3 Fused Silica is highly versatile.

The benefits of JGS3 Fused Silica are mainly derived from its excellent optical properties. Its low OH-content makes it a good candidate for optical systems. It is highly transparent in the visible and UV wavelength range. It is also very resistant to shock. Its high OH-content also allows it to resist bending. This material is an excellent material for photovoltaics. If you're considering using it in lasers, you should make sure that it meets the minimum requirements of the industry.

The highest purity JGS3 Fused Silica is the most popular choice for high-end optical devices. Due to its high OH-content, JGS3 is the ideal choice for semiconductors. Its low OH-content and high transparency make it ideal for semiconductor and optical applications. This material is also excellent for machining in the pharmaceutical and chemical industries. You can find it in your local market. In addition, JGS3 is a popular choice for high-end glass.

High transparency: This material has the highest transparency. The high OH-content of JGS3 makes it a great choice for high-end optical devices. Its low OH-content makes it a good candidate for use in optical materials. It is also ideal for a wide range of applications. Among its uses are in a variety of industries. For example, optical parts for semiconductor manufacturing are made of glass that can withstand a higher OH-content.

The highest transparency and low OH-concentration of JGS3 Fused Silica are common in semiconductor applications. Its low OH-content is beneficial for optical parts in the semiconductor industry. It is transparent over a wide spectral range of wavelengths, including the visible and deep UV. Despite the high OH-content, JGS3 Fused Silica has a high degree of transparency.

A thin fused silica wafer is a transparent, amorphous material that has high transmittance and low thermal expansion. Its thermal expansion coefficient is small, and it can withstand extreme temperature changes. A glass heated to 1100°F will not explode in water at room temperature. Additionally, JGS3 Fused Silica has high light transmittance throughout the visible and infrared spectral ranges.

JGS3 Fused Silica for Optical Coatings

JGS3 fused silica is a popular substrate material for optical coatings due to its excellent optical and thermal properties. Here are some of the benefits of using JGS3 fused silica for optical coatings:

-

High transparency: JGS3 fused silica has high transparency across a wide range of wavelengths, making it an ideal substrate for optical coatings that require high transmission.

-

Low thermal expansion: JGS3 fused silica has a low coefficient of thermal expansion, which means that it is less likely to expand or contract with temperature changes. This property is important for optical coatings that require stability over a range of temperatures.

-

High laser damage threshold: JGS3 fused silica has a high laser damage threshold, which means that it can withstand high laser powers without being damaged. This is an important property for optical coatings used in high-power laser applications.

-

High chemical resistance: JGS3 fused silica has excellent chemical resistance, which makes it suitable for use in harsh environments or with corrosive chemicals. This property is important for optical coatings used in industrial or research applications.

-

High surface quality: JGS3 fused silica can be manufactured with a high surface quality, which is important for optical coatings that require a smooth and uniform surface. This property ensures that the coating will be free of defects and will have a high optical performance.

Overall, JGS3 fused silica is a reliable and versatile substrate material for optical coatings, offering excellent optical, thermal, and chemical properties that make it suitable for a wide range of applications.