I want to quote two inch fused Quartz wafer 1mm thick, single and double side polished wafer both. The Fused Quartz wafer will be used as substrate for MEMS fabrication.

JGS2 Fused Silica Wafers Optical Grade

JGS2 Fused Silica Wafers Applications

JGS2 Fused silica wafers optical and mechanical properties, as well as its high chemical durability make it advantageous to use

in advanced optical systems. Our JGS2 fused silica scratch/dig and tolerances are made to order for precision research and production of aspherical lenses and window mirrors made of fused silica in high-power laser projects.

JGS2 Fused Silica works great in Carbon based Micro Mlectromechanical Systems (C-MEMS). JGS2 Wafers have allowed researchers to fabricate strong, inexpensive and biocompatible micro devices for specific applications.

Buy JGS2 Fused Silica Wafers & Start Researching Today!

Get Your JGS2 Fused Silica Quote FAST!

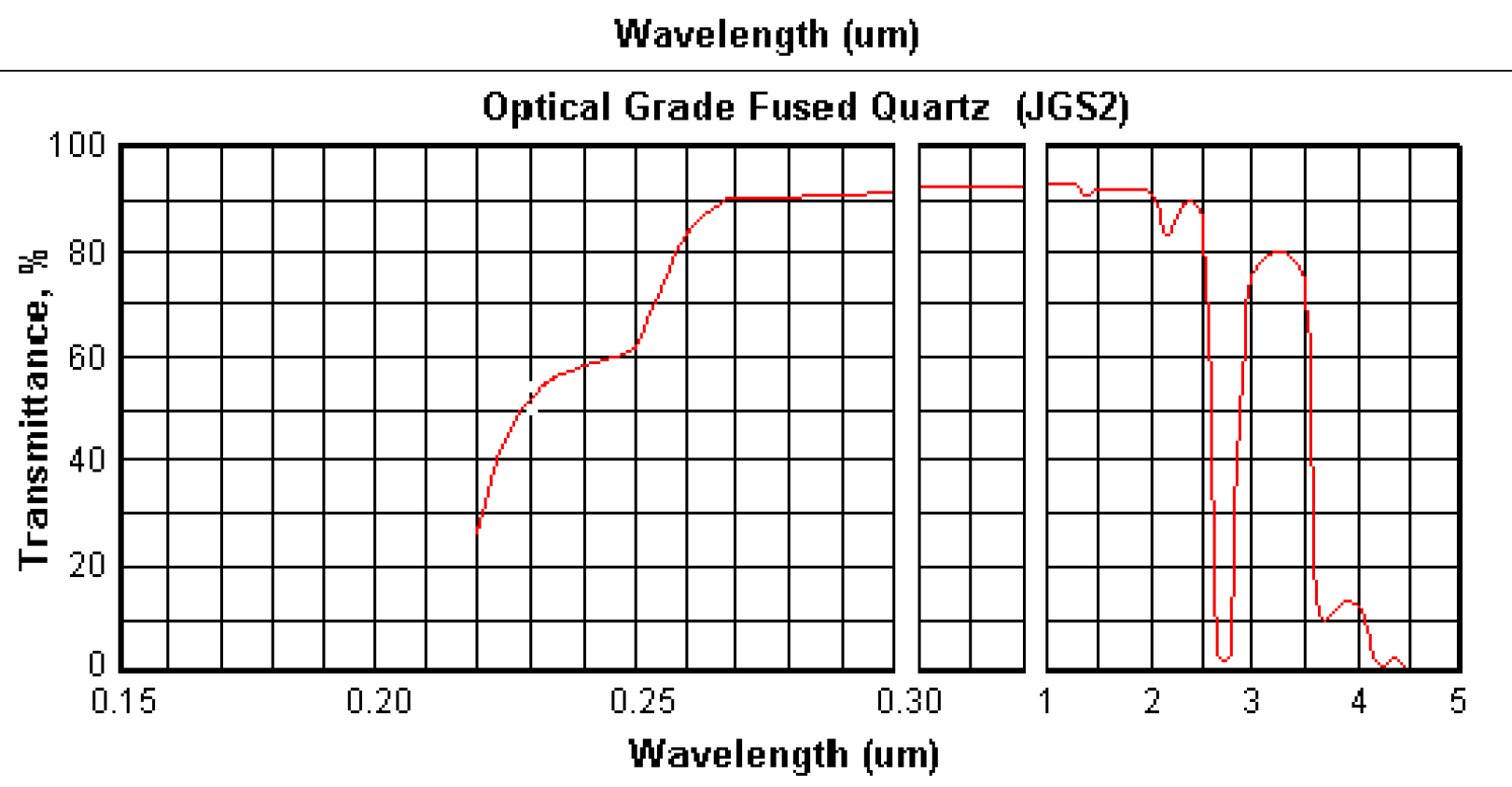

JGS2 Fused Silica Transmission Curve

JGS2 Fused Silica Used to Fabricate MEMS Devices

A MEMS university researchers requested the following quote:

What Is JGS2 Fused Silica Used For?

Fused silica has excellent optical properties and very low impurity content. It is very cheap compared to other types of optical grade quartz glass and is particularly suitable for applications requiring high-precision, high-transmission. JGS2 wafers are ideal for use as protective barriers for electronic sensors. In addition to being very inexpensive, JGS2 is also highly durable.

The JGS2 grade is the equivalent of Homosil 1, 2, and 3 (Heraeus) and Dynasil 1000, 5000, and 6000. Both are optically clear and possess excellent UV and visible transmission. The optical properties of JGS2 are almost identical to those of JGS1. However, larger pieces will have bubbles. This means that applications requiring high-purity performance should avoid this grade.

JGS2 Fused Silica wafers are transparent across the entire spectral range. In particular, they have no band gaps in the visible range. In addition, they exhibit excellent optical properties in the deep-UV and IR range. Despite its low price, JGS2 is still relatively expensive, and is used in many different applications. It is a superior choice over Silicon and Calcium Fluoride.

JGS1 and JGS2 are a class of fused silica. They are very similar to Suprasil 1 and 2, Spectrosil A and B (Saint-Gobain), and Dynasil 1100 and 4100. Their main characteristics are their high transparency in the ultraviolet and low IR regions and low haze, but they are not laser-damaging.

What Does JGS2 Optical Grade Fused Silica Mean?

When you need a substrate that can handle very high temperatures and work as an insulator in semiconductors, then JGS2 Grade Fused Silica Wafers is the right choice.

JGS2 Fused Silica is fabricated by refining gas with a raw crystal. JGS2 contains many metal impurities. JGS2's absorption peaks (hydroxyl content 100-200ppm) at 2730nm. JGS2 works great the wave band range of 220-2500 nm.

| Parameter Value | JGS2 |

| Max Size | <300mm |

| Tramission Range (medium transmission ratio) | 0.26~2.10um (Tavg>85%) |

| OH-Content | 150ppm |

| Fluorescence (ex 254nm) | Strong v-b |

| Impurity Content | 20-40 ppm |

| Birefringent constant | 4-6 nm/cm |

| Melting Method | Oxy-hydrogen melting |

Where Can You Buy JGS2 Fused Silica?

A large selection of fused silica windows JGS2 Optical Grade can be found here.

What Grades of Fused Quartz are Available?

Other fused silica wafer grades and their applications include:

JGS2 Fused Silica Optical and Mechanical Properties

JGS2 Fused Silica wafers have outstanding optical and mechanical properties. This material is transparent in the visible range and exhibits low absorption in the ultraviolet and IR wavelengths. Among its many uses, this material is often used in photovoltaic cells, solar panels, and semiconductors. It is also used for making precision instrumentation, including aspherical lenses and window mirrors. Its unique characteristics make it a great choice for carbon-based micromechanical systems.

Compared to other types of glass, JGS2 has very good thermal conductivity and high chemical purity. Its high temperature resistance makes it a preferred material in the optical industry. Its excellent physical and chemical properties make it a popular choice in optics and high-tech applications. As with other types of glass, it is extremely resistant to chemical and thermal shocks and is also non-hygroscopic.

As a chemical compound, silica is a compound of silicon and oxygen. This combination makes fused silica an ideal optical material. It is resistant to heat, has a wide operating temperature range, and is extremely laser-damaging. There are several types of JGS, including the UV and IR grades. These materials are available from several manufacturers and are equivalent to Suprasil 1 and 2 (Heraeus), Spectrosil A and B (Saint-Gobain), and Dynasil 4100 and 1110 (4100).

JGS1 Fused Silica is an excellent optical material due to its high chemical purity. It is also resistant to heat and cold. Its softening point is 1730degC. When it is heated to 1450degC, it is extremely stable and resists cracking. Its low impurity content also helps it withstand rapid temperature changes. Unlike most glass, it is resistant to chemicals and is thermal shock-resistant.

JGS2 is a high-quality material that is used in optical components. Its low impurities and excellent chemical purity make it an excellent choice for a variety of applications. While JGS1 is mainly used for optical applications that operate in the visible and ultraviolet wavelengths, it is also used in IR spectral range. It is an excellent alternative to other types of glass in the pharmaceutical and chemical industries.

Fused silica is a high-purity, low-refractive material with excellent optical properties. Its low impurity content makes it an ideal choice for a variety of applications. Its ultralow thermal expansion coefficient and excellent chemical resistance make it a great choice for optical components. These qualities make JGS2 wafers ideal for many different applications. This is why JGS2 Fused Silica is a superior choice for use in the pharmaceutical and chemical industries.

This high-grade fused silica wafer is a high-purity material that has been ground and polished to optical grade on both sides. It is used in a variety of optical applications, and it is compatible with most types of lasers and other components. Aside from being a highly efficient material, it is also extremely durable. Further, it can withstand very high temperatures without any degradation. Moreover, it can be used in a number of optical systems that operate at high temperatures.

JGS2 Fused Silica wafers have excellent optical and chemical properties. They are excellent in resisting heat and impact and are chemically pure. They are also resistant to alkali and acid solutions. Unlike other glass, JGS2 has a high thermal expansion coefficient. However, they do not resist extreme temperatures, making them a good choice for a variety of applications. Aside from being very durable, they are inexpensive.

JGS1 Fused Silica is a high-purity material that is ideally suited for optical applications. It is a chemically pure material and is very resistant to alkali and acid. It is used in many high-tech processes such as semiconductor fabrication and glass manufacturing. The JGS2 Fused Silica is the best option for optical applications where you need a high-purity material.

Its optical properties are exceptional. Its high transmittance in visible and infrared ranges makes it an excellent choice for a wide range of applications. Moreover, it exhibits low thermal expansion, making it an excellent choice for high-speed communication. And it is inexpensive compared to other optical grade quartz glass. It can also be used as a protective barrier for electronic sensors and detectors. For many other applications, JGS2 Fused Silica is a great choice.