Silicon Nitride (SiN) Depostion on Glass Wafers

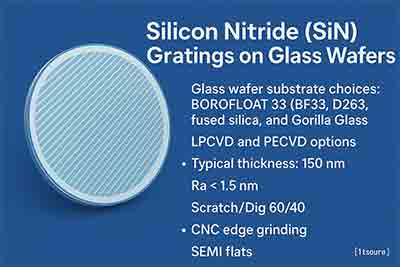

UniversityWafer, sells Borofloat 33 and other glass wafers that are deposited with Silicon Nitride (SiN) grating.

For example, our SiN coated BF33 wafers work great for Ion-sensitive field-effect transistors (ISFET's). Other glass wafers that work include:

Researchers have used the following item with great success!

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

Fabricating Silicon Nitride Waveguides and Photonic Devices

A researcher contacted us for the following help:

Our lab wants to make silicon nitride waveguides and photonic devices. Can I get a quote for 150 nm stoichiometric silicon nitride on glass wafers? (fused silica, borofloat33, and other kinds of glass wafers are fine, as long as the surface flatness is fine).

Dimensions say 4 inch glass wafers (100mm). Thickness doesn’t matter that much, depending on what options you have. The normal option like ~ 500 um would work. The deposited layer we want 150 nm of stoichiometric silicon nitride film. Quantity say 25 pcs. Please let me know if there are other options as well.

Basically we want the nitride to be deposited via LPCVD process (not PECVD), and the refractive index to be 2.00 with a reasonable tolerance, say+_0.05. Is this doable from UniveristyWafer?

UniversityWafer Replied:

We do have in stock the polished Silica (fused quartz) wafers described in GX32. We shall have the Silicon Nitride layer grown on them and we are waiting for a quote from the Nitride film grower for doing that.

The question arose if this should be a stoichiometric Si3N4 layer or a so-called Low-Stress Silicon Nitride layer which is a mixture of Si(x)N(y) compounds. When deposited on monocrystalline Silicon or monocrystalline Silicon with a Thermal Oxide (SiO2) layer, Si3N4 film has a residual stress in tension of about 1,000 MPa. When that is objectionable, one deposits Si(x)N(y) so composed as to have residual stress within ±100MPa.

If one wants to deposit a Silicon Nitride film on a polished Silica or Fused Quartz wafer, which is a polycrystalline surface, it is unclear what residual stress will result. This is what I am reviewing with the nitride film grower and is a cause of the delay.

If you wanted a Nitride film on a Silicon wafer with an SiO2 coating, then I could quote immediately (and it would cost less). If you want a Nitride film on a (more expensive) polished Silica or Fused quartz wafer then I have to review the matter more carefully, and this takes time.

LPCVD stands for Low Pressure Chemical Vapor Deposition and is the preferred method of depositing Silicon Nitride films. The process grows Silicon Nitride on both sides of the substrate wafers. An alternative is PECVD which is a process akin to sputtering, which deposits the Nitride on one side only.

The reactors for growing Silicon Nitride films, process 25 wafers at a time. Therefore it costs as much to process 25 as to process 10 wafers. All you would save is the cost of 15 substrates. But we shall send you a quotation for both 10 and for 25 wafers.

We offer (see minor correction to the wording of specifications):

Item Qty. Description

GX32. 25 Silica (fuzed quartz) wafers, per SEMI, P/P 4"Ø×450±15µm, SEMI Flat (one),

Both-sides-polished, TTV<0.5µm,

With LPCVD Super Low Stress Silicon Nitride, 150nm thick, on both wafer sides,

Residual Film stress <100 Mpa Tensile,

Sealed in Empak or equivalent cassettes

After a long review, it turns out that stoichiometric Si3N4 deposited on fused quartz wafers, does crack.

The only thing that will stay intact is Super Low Stress Silicon Oxide, which is a mixture of Si(x)N(y) compounds with Residual Stress < 100 MPa in tension. This is what we offer.

What are Silicon Nitride Grating Glass Wafers used for?

Silicon Nitride Grating Glass Wafers are specialized materials that find applications in various industries, primarily in the fields of photonics, telecommunications, and integrated optics. They consist of a silicon nitride (Si3N4) grating pattern on a glass substrate. These wafers have unique properties such as low optical loss, high thermal stability, and excellent mechanical strength, making them suitable for multiple purposes. Some common uses include:

Optical filters: Silicon Nitride Grating Glass Wafers can be used as optical filters in wavelength division multiplexing (WDM) systems, which allow multiple optical signals to be combined and transmitted over a single fiber. They can separate specific wavelengths of light to optimize the performance of optical communication systems.

Biosensors: Due to their biocompatibility and low optical loss, these wafers can be utilized in biosensing applications. They can help detect and monitor biological molecules, such as proteins, DNA, or RNA, which can be crucial for medical diagnostics and research.

Integrated optics: Silicon Nitride Grating Glass Wafers can be employed to create integrated optical devices, such as waveguides, splitters, and couplers. These devices can be used to manipulate light signals in various optical systems, including telecommunications, sensing, and computing.

Diffraction gratings: The grating pattern on the wafers can be used as a diffraction grating, which can separate light into its constituent wavelengths. This property can be utilized in spectroscopy, an analytical technique used in various scientific and industrial applications, such as material characterization, chemical analysis, and environmental monitoring.

Micro-electromechanical systems (MEMS): The unique mechanical and thermal properties of Silicon Nitride Grating Glass Wafers make them suitable for use in MEMS applications, such as accelerometers, gyroscopes, and pressure sensors.

In summary, Silicon Nitride Grating Glass Wafers are versatile materials with applications in various industries, primarily in photonics, telecommunications, and integrated optics. Their unique properties make them valuable for optical filters, biosensors, integrated optical devices, diffraction gratings, and MEMS.

Silicon Nitride Grating Glass Wafers

Experimentally, a compact polarization beam splitter (PBS) based on a silicon nitride silicon insulator platform was demonstrated in combination with a recently proposed augmented low-energy photodiodes (LAD). The unit is a microprocessor - a controlled spectrophotometer with 512 detectors integrated into a single silicon chip photodiode array. P - sup - gt - lt and LT-gt - p - t as well as a guided waveguide structure for the detection of light from the photoderms. We have produced an integrated silicon-illuminated photode array detector, which is used with a high-speed photometry instrument as a combined backward-backward spectroscopy method for high-speed photometry instruments. This unit is the result of the development of a new microprocessor - controls - one - microchip spectrometer (MOSFET) to integrate 512 detectors on a single silicon chip array (photodicode) and integrate these detectors into the same chip. [Sources: 2, 5]

The microfabricated structure is a silicon nitride membrane substrate that is flexible enough to be used in a variety of applications such as photodiodes. [Sources: 1]

The silicon nitride ceramic is processed in such a way that the isalon produced from the ceramic becomes soft at about 1,000 degrees. The silicon-rich silicon nitride film is sensitive to XeF-2 etching and can be removed with an etching interferometric modulator. [Sources: 2, 3]

The silicon-rich silicon nitride composition can be adjusted to maximize the refractive index and minimize wavelength absorption (908b). By changing the concentration of silicon, nitrogen and hydrogen (see e.g.), the wavelength of the absorption for the 1.9 nm and 2.830 nm waveguides can be adjusted from 3.2 to 2.830 nm. [Sources: 6]

As described below, we have discovered, for example, that silicon-rich silicon nitride can be easily removed by using XeF 2 caustic agent to remove the sacrificial layer [102]. As described, the use of silicone-212, 232, 213, 213, 114, 119, 126, 127, 138, 136, 137, 155, 203, 204, 208, 212, 212, 212, 212, 212, 212, 212, 212, 212, 212, 212, 212, 212, 212, 212, 212, 212, 212, 212, 212, 212, 212, 212, 212, 212, 212, 212, 212, 212, 212, 212, 212, 212, 2 [Sources: 3]

The native silicon dioxide layer is located on the exposed surface at a certain level, at which a number of cavities (703) are formed in a replacement handling structure (400). In this version, the replacement grip structure corresponds to a silicon layer and the silicon nitride layer. The silicon oxide layer at the top of the cavity forms at specified levels, while the spare parts form structures at 400 levels that lie at specified levels. In the absence of another layer (200), a native silicon-nitrite layer forms at the bottom of a cave with a certain amount of silicon oxides. The structure of the replacement handles in the given levels is formed by a number of cavities (700). [Sources: 4]

Like silicon oxides, the silicon nitride layer also offers an extremely smooth and uniform interface, which makes it possible to observe color interference under the microscope. In this embodiment, the first layer of silicon dioxide has a vertical thickness of about 1 micrometer and a surface area of less than 100 nanometers. The second layer, silicon oxide, has a vertical thickness of about 1 micrometer, and the silicon nitride layer has a vertical thickness of about 100 nanometers, as indicated by the ellipsometry analysis that was taken into account in the design of the replacement handle structure. [Sources: 1, 4]

Ring-to-ring compression tests compared the thickness of the supporting thick silicon ring and the free-standing ultra-thin silicon. The results indicate that the waveguide structure effect is dominated by this effect, and no significant difference between PVD and PECVD - deposited SiO 2 - has been observed. In addition, the sensitivity is increased from an average of 22% to 30% from 9 pm to 11 pm, with an average of 30-40% for both the silicon nitride and the silicon oxide layer. [Sources: 0, 6]

The breaking force of the supporting thin silicon is significantly lower than that of the free-standing silicon, but not as strong as the strong force of the silicon oxide. [Sources: 0]

We are presenting here the use of silicon nitride substrates as a means of overcoming these obstacles. The substrate consists of an amorphous, low-stress silicon nitride mounted on a silicon wafer, and the oxide layer is produced by stripping off its oxide layers. This etching layer - stop layer embeds the silicon advantageously - is rich in silicone nitride, which can then be removed with the help of a thin layer of etching stops, as in the case of graphene. [Sources: 1, 3]

In addition, silicon-rich silicon nitride has a refractive index that is about half the wavelength of the process. In addition, it has an optical conductivity of about 1.5 micrometers per square centimeter, which is equivalent to that of a silicon wafer. [Sources: 6]

In this graph we can see that a sufficiently low optical absorption can be achieved with silicon-rich silicon nitride, which has a refractive index of 2.75 at 830 nm. [Sources: 6]

Sources:

[0]: https://onlinelibrary.wiley.com/doi/full/10.1002/inf2.12087

[1]: https://kundoc.com/download/silicon-nitride-membrane-substrates-for-the-investigation-of-local-structure-in-_5a532726d64ab25d7d7543de.html

[2]: https://worldwidescience.org/topicpages/p/pecvd+silicon+nitride.html

[3]: https://patents.google.com/patent/US7382515B2/en

[4]: http://www.freepatentsonline.com/y2020/0021079.html

[5]: https://suranafashion.com/cecv/photodiode-array-spectrometer.html

[6]: https://www.google.com/patents/US20070122077