Remote Epitaxy That Bonds Graphene to Silicon & Gallium Arsenide

Wafers for Remote Epitaxy

Researchers from MIT have created a Graphene film that bonds Silicon and Gallium Arsenide wafers easily and inexpensively.

UniversityWafer, Inc. and our partners can produce small pieces as well as 2" Gallium Nitride Templates using remote epitaxy.

Let us know how this new service can help you!

Get your Quote FAST!

Powering the Next Generation Electronics With Remote Epitaxy

Watch the video below! Let us know if you have any questions.

What are the Step to Fabricate Remote Epitaxy?

The first steps in the Remote Epitaxy process involve the growth of an epitaxial seed layer. Using ultrathin graphene as a template, researchers are investigating the potential of this growth method to produce nanoscale graphene layers. These films can be deposited onto freestanding GaN substrates and have crystalline qualities. These films can also be transferred to foreign substrates. The epilayers formed by this method are heteroepitaxy and homoepitaxy.

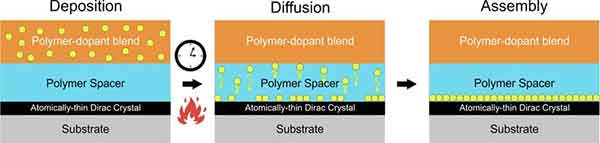

The process uses a thick wafer substrate coated with a graphene-like material to facilitate the removal of the epitaxial layer. This keeps the original substrate wafer intact while reducing the costs of the chip. It is also possible to stack the films into a multifunctional device and then stack them in a different pattern. The process can be repeated hundreds of times without reprocessing. This technology is widely used in semiconductor manufacturing and is particularly useful in the manufacture of compound semiconductors.

Remote Epitaxy can be applied to different materials. Graphene is used for the epitaxial layer and is an ideal substrate for this application. The substrates used for this process include silicon, carbon, and polysilicon. The thin films can be stacked into heterogeneous multifunctional devices. This technology has a wide range of applications and has been shown to significantly reduce the cost of chip production.

Graphene is one of the most recent substrates used for Remote Epitaxy. Graphene allows lifting off the epitaxial layer and reusing the substrate. It is important to note that this technology is very expensive and requires extensive research. In this case, the cost of a single chip can be cut by half. By the same token, the process allows for the production of flexible devices.

The second type of substrate used in Remote Epitaxy is graphene. The graphene-coated substrates are extremely inexpensive and can be reused for another process. The use of a thin graphene-coated substrate is an advantageous aspect in Remote Eptaxy because it allows for the reuse of non-silicon substrates. It also reduces costs for the production of chip-sized semiconductors.

In contrast, remote epitaxy uses a thick wafer substrate and an intermediate layer of graphene to support the epitaxial layer. The thin film grows on top of the substrate, leaving the original wafer intact. The process also allows for the production of free-standing films, which are stacked together to create a heterogeneous multifunctional device. There are many advantages to using this technique in semiconductor manufacturing.

Unlike traditional methods, Remote Epitaxy requires the use of thick wafer substrates for the growth of semiconductor crystals. Unlike traditional processes, it is a non-toxic process. It is ideal for applications in semiconductors, as it does not require any chemicals. This process also enables the development of devices that have multiple functions. For example, in the manufacturing of high-speed electronic components, the technology allows for the fabrication of a thin conductive film.

Remote epitaxy uses a thin wafer substrate with a layer of graphene to enable the epitaxial growth. This method can also be used on a heterogeneous multifunctional material. The process is advantageous because it uses a thin substrate to produce chips. While the process does not require the use of a thin wafer, the technology does not involve the use of a thick substrate with graphene.

The process relies on a thick wafer substrate with an intermediate layer of graphene, which is a very flexible material. In this way, it is possible to remove and reuse the epitaxial layer without damaging the substrate. The process can also be performed with a thin film of a non-silicon material. During this process, the film is transferred from one substrate to another. It is not necessary to remove the original substrate, which allows for a flexible device to be manufactured on the same wafer.

Unlike with conventional lithography, Remote Epitaxy does not require a thin-film substrate. Instead, it uses a polycrystalline substrate. Using this method, thin-films are grown on a polycrystalline substrate. The results are very similar to those of the epitaxial process. Despite the similarities between the two processes, the process is more complicated. In some cases, it is impossible to transfer an epitaxial GaN film to a monolayer graphene surface.

Remote Epitaxy Could Revolutionize the Semiconductor Industry

The new technology, called remote epitaxy, is a great step forward for a number of technologies. The process allows researchers to create flexible wearable electronics, and has the potential to revolutionize the semiconductor industry. By heating graphene on a gallium nitride substrate, they can create a replica of a semiconductor substrate. Then, the film can be peeled off and the silicon is ready for use.

The new technology, called remote epitaxy, is a great step forward for a number of technologies. The process allows researchers to create flexible wearable electronics, and has the potential to revolutionize the semiconductor industry. By heating graphene on a gallium nitride substrate, they can create a replica of a semiconductor substrate. Then, the film can be peeled off and the silicon is ready for use.

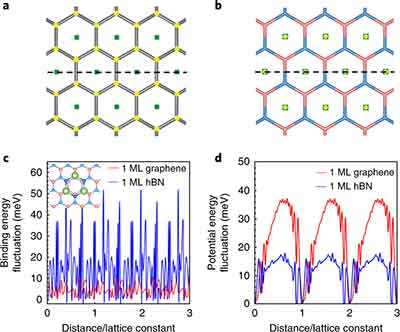

Currently, the process is only able to create monolayers of semiconductor materials. However, when graphene is deposited on top of a high-cost wafer, it can interact with the underlying material and assemble into a single-crystalline pattern. Eventually, remote epitaxy could revolutionize the semiconductor industry and drive down costs for consumers. Until then, however, many of these applications have been hampered by expensive wafers and processes.

Medical Devices Fabricated Using Remote Epitaxy

Despite the low cost of the process, it is still an expensive option. However, if silicon is a cheaper, more abundant material and is suited for remote epitaxy, the technique could make new flexible medical devices. This could make medical devices more versatile and more functional than ever before. If the process is successful, it could also be used to create biocompatible, stretchy electronics that can be applied to human tissue. Further, it could be applied to other applications, such as solar-powered skins and virtual reality contact lenses.

Fabricatin Flexible Semiconducting Films Using Remote Epitaxy

For example, researchers can now produce flexible semiconducting films using remote epitaxy. The technique is more flexible than traditional IR lithography, and Kim and his team are working with six major companies in Korea, Japan, and the United States. The technology is already in use in several fields, including photonics, wearables, and IoT. The potential for remote epitaxy is great. It could be a game changer in the future.

What Materials are Used with Remote Epitaxy to Grow 2D Materials

Using remote epitaxy to grow 2D materials is a great way to reduce the cost of semiconductor materials. The process can be adapted to other materials, such as silicon or graphene. Nevertheless, it requires very low-cost silicon wafers. This technology is also more efficient than other types of wafers. This method is also a better alternative to manufacturing silicon-based electronics. If this technique is used in other industries, it could make the process even more affordable.

The technique is also useful for making single-crystalline overlayers. The top layer can be dictated by the top layer, or by a wafer. In both cases, a wafer has two different ionic charges, and one can create a single-crystalline overlayer on it. This is the most common method for forming semiconductors. Its versatility allows it to be used in other applications, such as solar cells and nanotubes.

Graphene-Based Electronics Remote Epitaxy Benefits

This process is also more efficient in manufacturing graphene-based electronics. It allows researchers to create multiple thin flexible films on a single wafer. The cost of the wafer can vary, and it is often costly. As a result, remote epitaxy has been more widely adopted in many industries. This is good news for many sectors, including the semiconductor industry. The technique is a breakthrough for the manufacturing of flexible, wearable, and modular electronic devices.

Remote Epitaxy Through Graphene

Unlike the traditional method, remote epitaxy can be used to manufacture a variety of materials. Graphene, for instance, is a miracle material, which was accidentally synthesised in Manchester in 2008. The process is so complicated and costly, it is prohibitively expensive. The process, however, has a wide range of applications, from solar cells to high-performance optoelectronic devices. These materials can be produced in large amounts and used to manufacture electronic components.

Graphene can be manufactured on different types of substrates, and is a new way to manufacture semiconductor devices. The technique has the potential to create devices with many uses. A poly-domain graphene can be used for the overlayer. This process is more versatile than conventional semiconductors. The technology can also be used for other materials such as graphene, including metals. Its versatility is unmatched and has been proven useful in the manufacturing of electronic products.

Creating Semiconductor Films Using Remote Epitaxy

Remote epitaxy has been used to create semiconductor films. The technique is particularly useful in the semiconductor industry, as it allows the manufacture of multiple layers of materials. The process is ideal for obtaining ionically-conducting materials, and is an excellent tool for the manufacturing of devices with semiconductor-grade silicon and germanium. This technology is an excellent solution for duplicating semiconductor materials. The process is not applicable for silicon or germanium, which are ionically neutral.

Remote Epitaxy Research

In this lecture I will discuss emitaxation-based material-based layer transfer and its applications in materials science and engineering. In a paper published today in the journal Nature, researchers have shown that they can use "remote epitaxial" to produce freestanding films from functional materials, and in a presentation at the American Chemical Society's (ACS) annual meeting in Washington, D.C., they will discuss their work on flexible semiconducting films. Researchers have used Remote Epitaxa to create flexible semiconductor films from a chemical compound of oxygen known to have a wide range of electrical and magnetic properties, as well as a number of other useful properties such as thermal stability, electrical conductivity, magnetic conductivity and conductive properties of materials, and energy storage and transmission. With this paper, published today in the journal Nature, researchers show that we can use "remote" epitaxy to produce flexible and functional films with a high degree of freedom and flexibility, and to produce freerands of films without functional material. [Sources: 2, 4, 5, 6]

When researchers grow semiconducting films, they can peel them off graphene - coated wafers - and reuse them, which can be expensive depending on how they are made. A single crystalline film can easily be detached from a slippery graphene surface, and the graphene-coated substrate can then be reused to create another single crystalline film. While growing the semiconductor films themselves, researchers can peel them off and reuse them on a wafer that is expensive depending on the type of manufacture, or reuse them on another wafer. [Sources: 0, 2]

The demand for non-Si electronics has increased significantly in recent years, as current and next generation electronics require new functionalities that can never be achieved with Si-based materials. This means that new features are needed all the time, and they will increase significantly over time, requiring new functionalities that are never achieved with Si-based materials such as semiconductors. In fact, it has increased significantly in recent decades, because current or next-generation electronics require new functions and capabilities that can always be achieved with novel materials - but not with the same efficiency as using a Si-based material or semiconductor. [Sources: 1, 7]

Growing different crystalline materials on top of each other is not an easy task, as the grid parameters must be adapted to the interface between epilogue and bulk material, which cannot be done in the same way as at the interfaces between epilogue and bulk material. [Sources: 9]

Traditional epitaxy techniques, in which materials grow on a wafer at high temperatures, combine materials to match their crystalline patterns, Kim said. But traditional epitaxial techniques, which allow the material to grow at high temperature in an openafer, combine the materials so that their crystals and patterns match, he said, and they can be combined in the same way, matching the crystalline pattern of their materials. Traditional epitaxy technique that cultivates materials at high prices "It combines materials in a single - atomic - thick layer of a single wafer, but it doesn't bond them in a way that they match the" crystalline "patterns of each material," Kim said. At higher temperatures, they combine the material not in a 1: 1 ratio, but in a 1: 1 ratio. It cannot be combined with any material to match the crystals or patterns of the individual materials. [Sources: 2, 4]

It is imperative to investigate how distant heteroepitaxial relationships are determined by the underlying wafer substrate in the presence of mono, has been discovered in distant epitaxy respectively. Cs, corrected by scanning transmission electron microscopy, revealed the existence of a single - atom-thick - layer of the same material on two different wafers at a ratio of 1: 1. [Sources: 1, 8]

These results show that flexible electronics can be remotely produced from combinations of materials with different functionalities that were previously difficult to combine in one device. These thin, flexible devices could consist of layers that encompass computer systems and produce self-fed, stacked chips with a variety of functions and capabilities, such as sensors, actuators, and sensors. [Sources: 2, 4]

The so-called remote epitaxy technique is attractive because it can coat a substrate with graphene and transfer it to another graphene layer. The concept proposes a method to copy and glue any type of monocrystalline film as a 2D material onto the substrate below, then release it quickly and transfer it to the substrate of interest. This allows semiconductor films to be copied onto an underlying substrate, and this technique, known as "remote epitaxial techniques," is attractive because it can coat or transfer graphene to any substrate, graphene layers, etc. [Sources: 1, 6]

According to Kim, the group's technology allows manufacturers to use graphene as an intermediate layer, allowing them to copy and paste a wafer, separate the copied film from the wafers and reuse it many times over. [Sources: 3]

In a distant epitaxy, researchers can use different reusable wafers to make a series of different films and stack them, "says Kim, a postdoctoral researcher in the Department of Materials Science and Engineering at the University of California, San Diego. In the past, the researchers had to produce them with a different but reusable wafer and stack them in one layer due to the high production costs. The researchers could have produced them by using multiple layers of graphene and stacking them together in a layer using a computer, and they can now do so in two or three layers using a new technology. He said the researcher could have done it with another reusable wafer, he could have built it and stacked it, or all at once with an intermediate layer. [Sources: 2, 4]

Sources:

[0]: http://www.bu.edu/eng/departments/mse/news/mse-colloquium-series-spring-2018-and-other-events/mse-colloquium-jeehwan-kim-massachusetts-institute-of-technology/

[1]: https://www.universitywafer.com/graphene-remote-epitaxy.html

[2]: https://www.sciencedaily.com/releases/2020/02/200207095424.htm

[3]: https://m-cacm.acm.org/careers/216200-not-stuck-on-silicon/fulltext

[5]: https://www.thegraphenecouncil.org/blogpost/1501180/Graphene-Updates?tag=Jeehwan+Kim

[6]: https://optoelectronics.ece.ucsb.edu/index.php/node/711

[7]: http://physics.snu.ac.kr/boards/colloquium?md=v&bbsidx=5319

[9]: https://physicsworld.com/a/transparent-graphene-could-advance-non-silicon-electronics/

Epitaxial Graphene

We are all aware of monolayer films of graphite. Epitaxial graphene is a two-dimensional version of this  material. This material has been observed on a variety of surfaces, including Ni, Pt, and Ru. Until 2001, it was not considered a viable technology for practical applications. In 2003, it was deemed a promising material for electronics, but it was only in 2004 that the scientific evidence supporting its application was backed up by experiments. A patent for a new type of electronic device was issued in June 2003, and epitaxial-graphene-based electronics has been on the market since.

material. This material has been observed on a variety of surfaces, including Ni, Pt, and Ru. Until 2001, it was not considered a viable technology for practical applications. In 2003, it was deemed a promising material for electronics, but it was only in 2004 that the scientific evidence supporting its application was backed up by experiments. A patent for a new type of electronic device was issued in June 2003, and epitaxial-graphene-based electronics has been on the market since.

The epitaxial-graphene process was first developed in 1962 by D.V. Badami, who studied samples using X-ray diffraction. He determined that the c-axis of graphite ran through a hexagonal SiC crystal. A few years later, Van Bommel and colleagues carried out electron-diffraction experiments and showed that epitaxial-graphene is a structure that develops on the surface of a hexagonal SiC crystal.

In the early 1960s, D.V. Badami conducted the first experimental work on graphitization of SiC crystals. Then, he used X-ray diffraction to reveal that graphite is a chiral material. Another research team led by Van Bommel et al. investigated hexagonal SiC crystals and found that they had a unique graphite structure on the surface.

The epitaxial graphene research team at Georgia Tech led by Walt de Heer, has discovered a new way to create graphene on silicon carbide. This method is known to be more efficient than conventional methods, and it has been deemed a breakthrough by the industry. Besides its practical use, epitaxial graphene also has potential as a new electronic material. With the growing trend of using single-crystal substrates, this material is a promising alternative to traditional silicon materials.

The epitaxial graphene is a composite of two non-interacting graphene sheets. One sheet is highly charged, while the other is less charged. Several studies of epitaxial graphene have shown that it exhibits anomalous phase-transition-like properties. Its electrochemical properties show a high degree of tunable symmetry between epitaxial graphene layers. This makes it a superior candidate for many applications.

Because of its extraordinary properties, epitaxial graphene is a promising candidate for applications in electronics. Its low-energy atoms and high-vacuum conditions make it a useful material in many applications. Its crystalline structure allows it to be used in a wide range of temperature and pressures. The main drawback of epitaxial graphene is its instability. This material is unstable and can only be grown in a vacuum.

This research focuses on the chemistry behind the formation of epitaxial graphene. Its structure has an electric field of a single atom, so the material can be shaped into various shapes. The electrochemical effect of the graphene is a great example of a semiconductor. Its magnetic properties allow it to store and transmit current. Its unique electrical properties allow it to be used in a wide range of applications.

Its unique properties make it an excellent material for a variety of applications. Its properties can be controlled through the use of nanoscale devices. The graphene on silicon carbide is not an ultrathin material. Its structure is multilayered. Its band structure is related to the Dirac cone. Hence, it is useful for many different industries. If you are in the market for a graphene-based device, then this is the material for you.

For the fabrication of electronics, epitaxial graphene is an excellent choice. It is an ideal material for semiconductor applications. Its electrical properties are similar to the electrical properties of silicon. Because of its superior electrical properties, this material is an excellent candidate for electronics. The use of silicon in a semiconductor requires an atom-level oxygen barrier to prevent the flow of current. In this case, this layer is characterized by a thin film of carbon on the surface.

In addition to semiconductor applications, epitaxial graphene has been studied for its unique electronic properties. Initially, researchers were interested in its properties, but they were not satisfied with the results. The materials in question were amorphous and had low mobility. In contrast, graphene on silicon carbide had a higher temperature and reduced resistance. The materials in question have a much lower mobility than their counterparts.

Video: Defining Epitaxial Graphene